Quality Parts Made Easier, Faster

Create precision parts quickly and affordably with Robotika. Choose from CNC machining, vacuum casting, and rapid tooling with various materials and finishes. Get instant quotes, expert DFM feedback, and reliable low-volume production.

- 10+ years industrial experience

- 100+ plastic and metal materials available

- Parts delivered in as fast as 7 day

- 24/7 engineering support

Get Instant Pricing, Project Lead Time, and DFM Feedback

STEP | STP | SLDPRT | STL | DXF | IPT | X_T | X_B | 3DXML | CATPART | PRT | SAT | 3MF | JT files

- All uploads are secure and confidential.

Custom Production Services

Scale your production with Robotika’s strong production capability. Enjoy various manufacturing processes, flexible order volumes, and expert engineers. From prototyping to custom part production, we deliver quality at a reasonable price.

- Complete manufacturing equipment

- Fast and affordable parts in just a few days

- ISO 9001:2015, ISO 13485, ISO 14001, and IATF 16949 certified

Innovative Companies We Support

Our Manufacturing Capabilities

Explore Our Solutions by Industry Needs

Robotika empowers engineers and designers to turn concepts into reality with advanced manufacturing solutions. We leverage cutting-edge technology to provide on-demand CNC machining services for a wide range of industries.

Aerospace

We offer CNC machining services for the aerospace industry, delivering precise, lightweight, and high-strength components for flight systems.

Automotive

At Robotika, we provide automotive CNC machining services tailored to the automotive sector's high standards.

Communication

Robotika delivers CNC machining solutions for the communication industry, focusing on stable dimensional control and consistent batch production.

Electronics

Robotika supplies CNC-machined components for the electronics industry, supporting efficient assembly integration and demanding production environments.

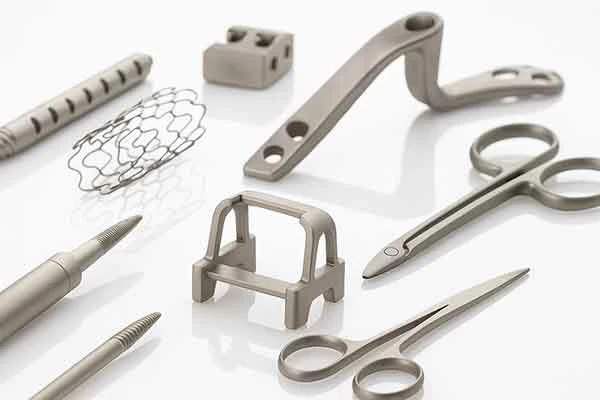

Medical Devices

Robotika provides CNC machining services for medical device manufacturers, delivering clean, traceable, and highly controlled components.

Industrial Equipment

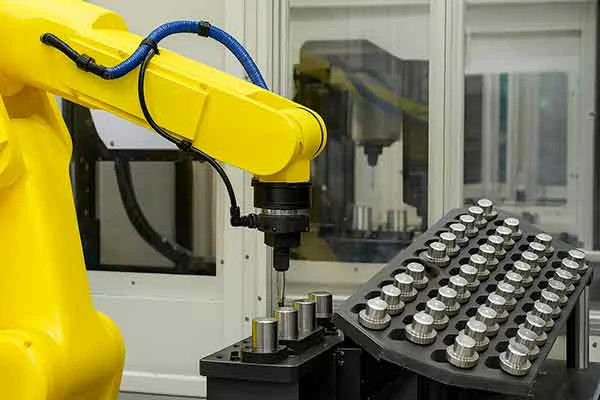

Robotika supplies CNC-machined parts for industrial equipment, built to perform reliably under heavy loads and continuous operation.

Robotics

Robotika focuses on CNC-machined parts for robotics equipment, supporting complex mechanisms, tight assembly fits, and long-term operational stability.

Consumer Products

At Robotika, we provide precision CNC machining services tailored to the consumer products sector's high standards.

New Energy

Robotika addresses the needs of the new energy industry with CNC machining for structurally critical and thermally demanding components.

Semiconductor

Robotika serves the semiconductor industry with high-precision CNC machining for ultra-clean, dimensionally controlled components.

Automation

We provide CNC machining services for the automation industry, supplying components for accurate alignment, reliable motion, and high-cycle operation.

Explore Our Recent Study Case

Discover how Robotika helps clients turn complex ideas into successful products with our latest case studies.

Services that Meet Your Parts Needs

Requirement Analysis

We gather detailed project requirements and technical specifications to fully understand your goals, ensuring that every step of the manufacturing process aligns with your expectations.

Material Selection

Our experts recommend the most suitable plastic or metal materials, carefully balancing mechanical performance, cost efficiency, and final product aesthetics to maximize overall project value.

Process Evaluation

We carefully evaluate manufacturing options, including CNC machining, injection molding, and casting, providing insights to choose the most effective process for your design.

Quote & Timeline

Receive fast, transparent quotations and highly realistic lead time estimates, helping you efficiently plan detailed production schedules with confidence and avoid costly project delays.

DFM Optimization

We refine your design through Design for Manufacturability analysis, reducing potential defects, streamlining production, and improving product performance and long-term reliability.

Material Compatibility Assessment

Optimize material selection to enhance performance, durability, and cost-effectiveness, ensuring a perfect match with the design.

Manufacturing Process Integration

Tailor your design to the most efficient manufacturing processes, increasing production efficiency, reducing waste, and optimizing cost-effectiveness.

Tolerance and Fit Analysis

Refine tolerances and fits to ensure perfect assembly, minimizing rework and defects, boosting product quality, and enhancing reliability.

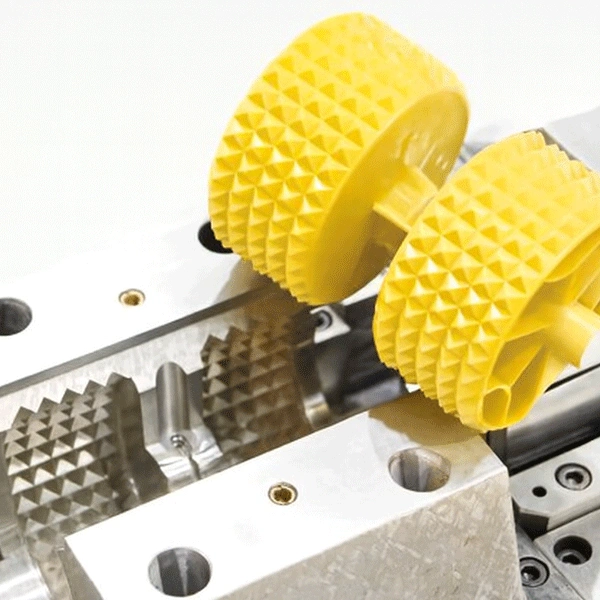

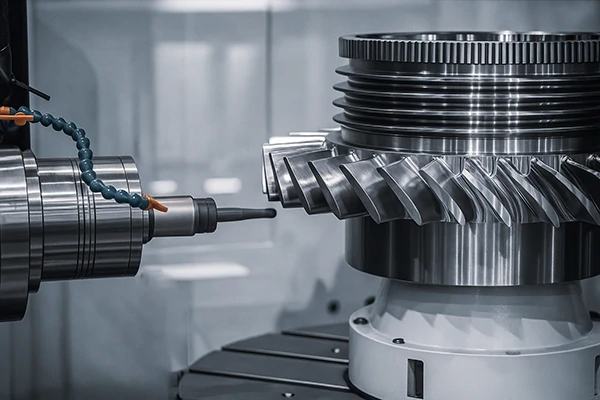

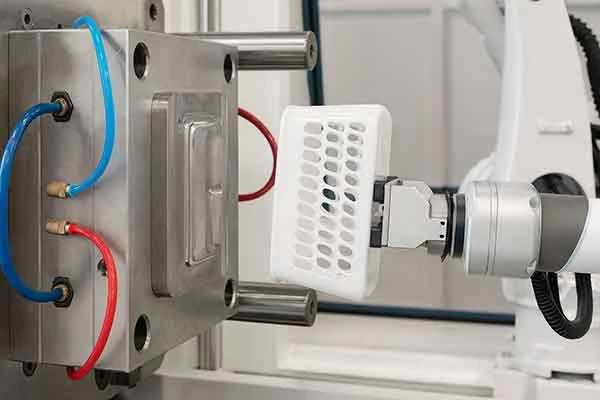

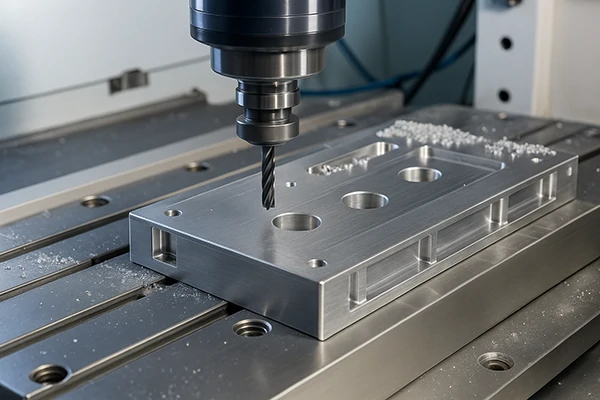

CNC Machining

We deliver accurate prototypes with CNC machining, allowing customers to validate performance, tolerance accuracy, and product functionality before mass production.

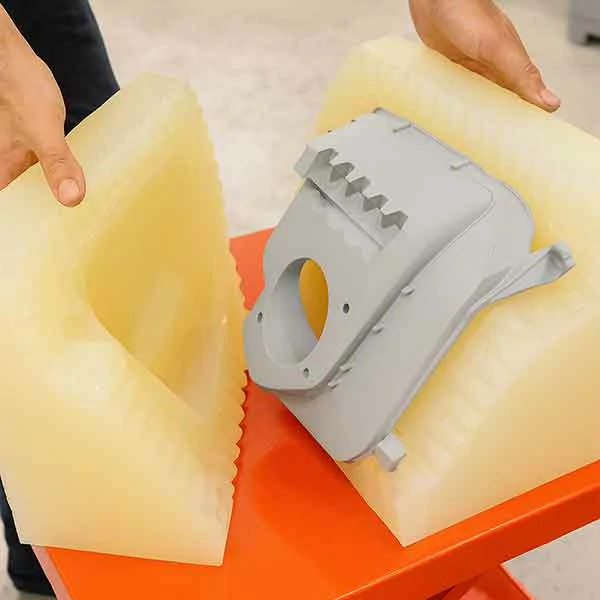

Vacuum Casting

Our advanced vacuum casting process enables rapid, highly affordable replication of plastic parts, closely and accurately matching end-use materials for functional testing and market evaluation.

Prototype Tooling

Bridge tooling creates short-run molds for realistic prototype testing, helping validate manufacturability and design efficiency before committing to full-scale production.

Functional Testing

Each prototype undergoes functional, dimensional, and appearance testing, ensuring the design meets real-world application requirements and customer performance standards.

Low-Volume Manufacturing

We provide bridge production solutions, producing small batches efficiently to validate market response and support pilot product launches before scaling up.

Mass Production

Our modern production lines deliver consistent, high-volume output with strict, advanced process control, ensuring stable quality and highly cost-effective manufacturing at global scale.

Quality Control

Through CMM inspection and ISO-certified systems, we maintain rigorous dimensional accuracy and product reliability, minimizing defects and ensuring customer satisfaction.

Cost Optimization

We carefully identify the most efficient materials and optimized processes, significantly reducing waste and overall costs while consistently maintaining high quality and fast delivery times.

Sandblasting

We enhance product appearance and texture with sandblasting, ensuring smooth surfaces that improve functionality and deliver a refined final finish.

Anodizing

Our anodizing process strengthens parts against wear and corrosion while offering customizable colors, creating durable and visually appealing components.

Polishing & Plating

We provide polishing and plating options that enhance durability and deliver premium aesthetics, ensuring your parts stand out in competitive markets.

Laser Marking

We add permanent logos, text, or serial numbers with precision laser marking, boosting product traceability, branding, and professional presentation.

Engineering Improvement

We analyze design and manufacturing performance, proposing improvements to enhance durability, efficiency, and competitiveness.

Cost Reduction

Our team identifies opportunities for material savings and process efficiency, lowering overall production costs without sacrificing quality or reliability.

Efficiency Boost

We streamline workflows and optimize cycle times, enabling faster production, reduced lead times, and greater responsiveness to customer needs.

Long-Term Support

Robotika builds lasting, trusted partnerships worldwide, offering ongoing expert support for design updates, product scaling, and long-term future project success.

Why Choose Robotika for Your CNC Machining Business

Create precision parts quickly and cost-effectively with Robotika. Choose from CNC machining, vacuum casting, and tooling services with various finishes. Get instant quotes and expert DFM feedback today.

10+ Years Experice

With over a decade of industry expertise, Robotika consistently delivers reliable CNC machining solutions trusted by global clients.

Advanced R&D and Manufacturing Capabilities

We leverage advanced R&D and state-of-the-art equipment to provide innovative manufacturing solutions for diverse customer requirements.

Professional Quality Certifications

ISO Certified processes and rigorous inspections guarantee precision, compliance, and consistent quality for every CNC-machined part.

Competitive Pricing

Our optimized workflows and material sourcing strategies ensure cost-effective CNC machining without compromising quality or speed.

Engineering Support & DFM Analysis

Robotika’s engineers provide DFM guidance, reducing risks, improving manufacturability, and ensuring efficient product development.

Fast Turnaround

Rapid quoting and efficient production systems enable quick production as fast as 7 days, helping clients meet urgent deadlines with confidence.

Your Ultimate CNC Machining Manufacturer

Robotika has a team of over 30 quality engineers who conduct comprehensive inspections at every stage of production, pre-production, production, and final inspection, to ensure a 90% first-pass pass rate.

Comprehensive Inspection Documentation

We provide detailed inspection reports, such as First Article Inspection (FAI), RoHS Compliance Certificates, dimensional measurements, and functional test results, to support your quality management.

Advanced Inspection Equipment

We use over 20 inspection tools, including CMMs, 2D measuring instruments, XRF analyzers, gauges, micrometers, and calipers, to check part dimensions, material quality, and surface finish.

Certified Manufacturing Partner

Robotika holds ISO 9001:2015, ISO 13485, and ISO 14001 certifications, making it a trusted partner for quality-critical industries such as automotive, medical devices, and consumer electronics.

How to Work With Robotika

Discover how easy it is to collaborate with Robotika, with streamlined steps from CAD upload to final delivery.

1. Upload a CAD File

Easily upload your CAD drawings and share project details to start your CNC machining process with Robotika.

2. Receive Instant Quote & DFM Analysis

Get fast, transparent quotations with expert DFM analysis, helping you reduce risks and optimize designs before production begins.

3. Prototype or Sample Production

We produce accurate prototypes or small-batch samples, allowing you to validate fit, function, and material quality before scaling.

4. Parts Delivered

Finished parts undergo strict quality inspection and are delivered on time, ensuring precision, consistency, and project success.

CNC Machining Manufacturer FAQs

What file formats do you accept for quotes?

We accept STEP, STP, SLDPRT, STL, DXF, IPT , X_T, X_B, 3DXML, CATPART, PRT, SAT, 3MF and JT files drawings. Just upload your CAD file and we’ll handle the rest.

How fast can I get a quote?

Most quotes are ready within hours. For complex projects, it may take up to 24 hours.

What is your typical lead time?

Prototypes can be shipped in as fast as 3–5 days. Production orders usually take 2–3 weeks depending on quantity and complexity.

Do you have a minimum order quantity (MOQ)?

No MOQ. We handle everything from one-off prototypes to full-scale production runs.

How do you ensure part quality?

All parts go through strict inspections, including CMM checks and ISO-certified processes, before shipping.

Can I request material certificates or inspection reports?

Yes. We provide material certifications, inspection reports, and even first article inspection (FAI) on request.

Do you ship internationally?

Absolutely. We ship worldwide with DHL, FedEx, UPS, and sea freight, depending on your project needs.

What payment methods do you accept?

We accept wire transfer (T/T), PayPal for small orders, and flexible terms for long-term partners.

What Clients Are Saying

Start Your CNC Machining Journey With Robotika

Contact us for design assistance, free quote, and expert advice today. We will reply you in 24 hours.