Custom 2K Injection Molding Services

We deliver end-to-end 2K injection molding solutions for global industries from automotive and medical devices to consumer electronics, with lead times as fast as 7 days.

- Tolerances down to +/- 0.02 mm

- Rapid tooling production as fast as 2 weeks

- Production-Grade Tooling

- Extensive range of injection molding materials

Start a New 2K Injection Molding Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

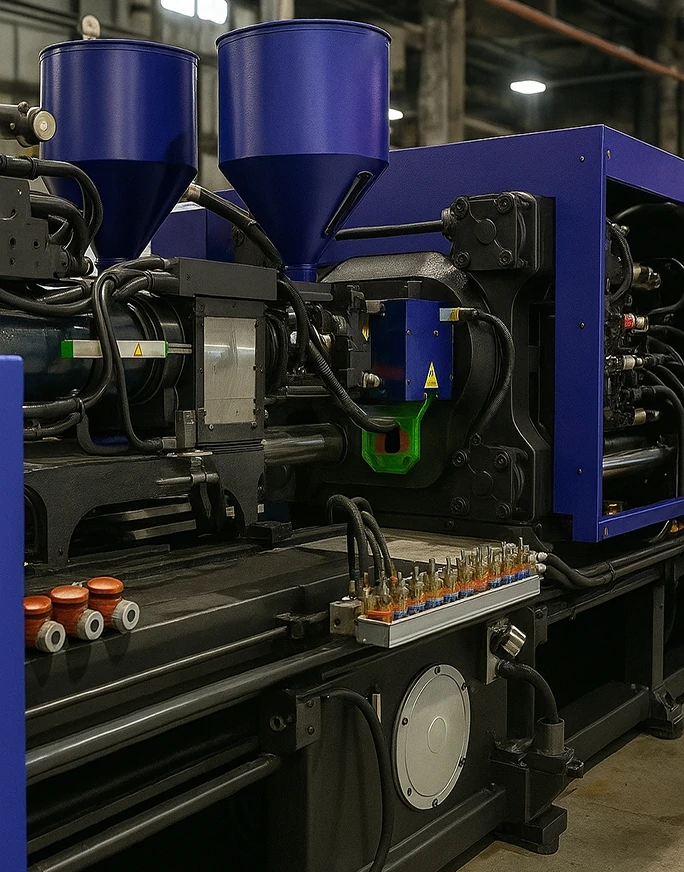

Reliable 2K Injection Molding Service Supplier from China

Robotika is a specialized 2K injection molding manufacturer in China. With over a decade effort, Robotika produces hundreds of thousands of injection-molded parts annually for customers worldwide. We are able to turn around rapid prototypes and high-volume production runs with tight tolerances—helping clients move from concept to market faster. We offer professional DFM (Design for Manufacturability) guidance, material selection support, and process optimization strategies to achieve the best balance between cost, durability, and appearance. Whether your project requires complex part geometries, strict dimensional control, or flawless cosmetic finishes, our engineering team ensures accuracy, repeatability, and full traceability—helping you avoid design pitfalls, reduce lead times, and ensure consistent part quality from prototype to production.

Our capabilities serve industries such as automotive, medical devices, consumer electronics, and industrial equipment. From startups to global OEMs, clients rely on us for flexible order volumes, competitive pricing, and responsive technical support throughout the product development lifecycle.

Our 2K Injection Molding Capabilities

Our capabilities cover multi-material & multi-color 2K injection molding—enabling us to deliver complex, functional, and visually appealing parts for a wide range of industries. We work with engineering-grade thermoplastics, elastomers, and specialty polymers, including ABS, PC, PP, PEEK, TPE, TPU, and glass-fiber reinforced materials, to meet both structural and cosmetic requirements.

To enhance performance and visual appeal, we offer a variety of post-molding surface treatment options, such as texturing, polishing, painting, laser marking, and plating. With precision manufacturing processes and advanced quality inspection, we can achieve tolerances of ±0.05 mm for production parts and ±0.02 mm for high-precision prototypes—ensuring every component meets strict dimensional accuracy and functional reliability standards.

2K Injection Molding Capabilities

Maximum Part Size

1200 × 1000 × 500 mm

Minimum Feature Size

5 × 5 × 5 mm

Minimum Wall Thickness

0.5 mm to 5 mm

Ribs/Gussets

thickness ranging from 0.5 mm to 3 mm

Mold Cavities

single-cavity molds, multi-cavity molds, and family molds

Mold Cavity Tolerances

R+/- 0.05 mm

Secondary Operations

Mold texturing, pad printing, laser engraving, threaded inserts, and basic assembly

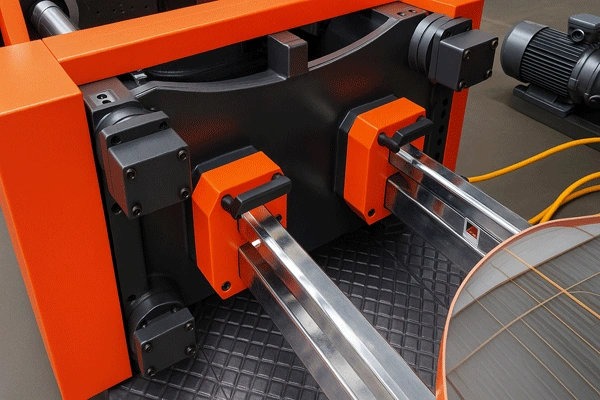

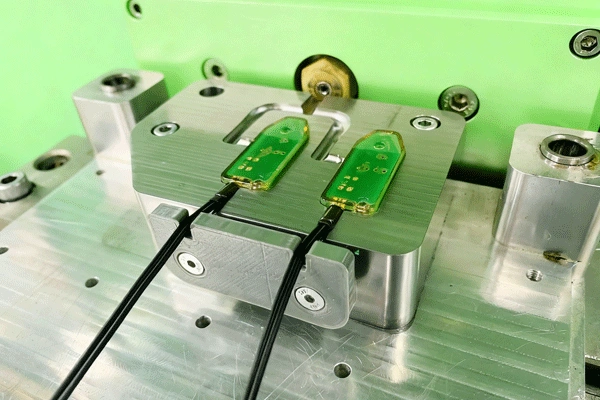

Our 2K Injection Molding Products We have Manufactured

From concept validation to mass production, each part reflects our tooling precision and molding expertise.

2K Injection Molding Tolerance

| Part Type | Tolerance Range |

|---|---|

| General Dimensions | ±0.05 mm – ±0.10 mm |

| Critical Dimensions | ±0.02 mm – ±0.05 mm |

| Part-to-Part Alignment (Between Two Materials) | ±0.05 mm – ±0.10 mm |

| Wall Thickness | ±0.05 mm – ±0.10 mm |

| Flatness/Warpage | ≤0.3 mm / 100 mm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

2K Injection Molding Materials

ABS

ABS (Acrylonitrile-Butadiene-Styrene) is one of the most commonly used plastics in 2K injection molding thanks to its toughness, dimensional stability, and ease of processing. It bonds well with other plastics like PC or elastomers such as TPE, creating durable, functional, and aesthetic dual-material parts. ABS is frequently applied in automotive interior panels, electronic housings, appliance handles, and consumer products requiring both strength and surface quality.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, textured, polished.

PP

PP (Polypropylene) is a lightweight, flexible, and chemically resistant material widely used in 2K molding. It is often combined with soft elastomers like TPE or TPU to achieve a balance of rigidity and elasticity. PP is ideal for caps, seals, automotive trims, packaging parts, and household products, offering excellent fatigue resistance. Its versatility and cost-effectiveness make it a popular choice for high-volume and consumer-oriented applications.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, matte, polished.

PE

PE (Polyethylene) is a versatile thermoplastic suitable for 2K molding due to its toughness, impact resistance, and strong chemical tolerance. It is commonly combined with elastomers to create flexible closures, seals, and packaging components. PE also finds use in consumer goods, storage products, and industrial containers where durability and resilience are important. Its low cost and ease of molding make it suitable for both high-volume production and daily-use products.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, matte, polished.

PS

PC (Polycarbonate) stands out in 2K molding for its outstanding transparency, toughness, and impact resistance. It is often paired with ABS to form strong yet visually appealing dual-shot components. PC’s high clarity makes it ideal for transparent covers, lenses, lighting housings, and medical devices. Its combination of strength and visual quality ensures reliable performance in demanding industries like automotive, electronics, and healthcare.

- Mill Lead Time: As fast as 4 days

- Finishes: Polished, textured, UV-coated.

PEEK

PEEK (Polyetheretherketone) is a top-tier engineering plastic offering unmatched strength, heat resistance, and chemical stability. In 2K molding, it is used for aerospace, medical, and industrial applications where performance is critical. PEEK parts are often paired with softer plastics or elastomers for added grip or protection. Common uses include surgical instruments, aerospace brackets, and industrial seals. Its reliability in extreme conditions makes it a premium material for specialized industries.

- Mill Lead Time: As fast as 7 days

- Finishes: Raw, polished, machined.

POM

POM (Polyoxymethylene, Acetal) is an engineering plastic that offers excellent dimensional stability, wear resistance, and low friction, making it well-suited for precision 2K molded parts. It is often paired with elastomers or rigid substrates for added functionality. POM is widely applied in gears, fasteners, mechanical components, and automotive fuel system parts, where long-term reliability is essential. Its ability to maintain strength and precision under stress makes it a preferred choice.

- Mill Lead Time: As fast as 4 days

- Finishes: Raw, polished, textured.

PA

PA (Nylon, PA6/PA66) is a high-strength plastic commonly used in 2K molding for its toughness, wear resistance, and thermal stability. It is often combined with elastomers like TPE to add flexibility in functional areas. Nylon is widely applied in automotive under-the-hood components, electrical housings, and industrial fasteners, where both mechanical strength and heat resistance are critical. Glass-filled grades further improve rigidity and dimensional stability for demanding applications.

- Mill Lead Time: As fast as 4 days

- Finishes: Raw, polished, glass-filled.

TPU

TPU (Thermoplastic Polyurethane) is a highly elastic and durable plastic ideal for soft-touch applications in 2K molding. It bonds effectively with rigid substrates like ABS and PC, creating dual-shot products that combine strength and flexibility. TPU is widely used for grips, seals, phone cases, and protective casings due to its abrasion resistance and clarity. It is also a favored choice in sports equipment and wearables requiring both comfort and durability.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, polished, textured.

Finishing Options for 2K Injection Molding

| Name | Description | Can Be Applied with | Applicable Materials | |

|---|---|---|---|---|

|

Polishing | Creates a smooth, glossy surface finish, often used for clear or cosmetic parts. | Manual or automated polishing tools | PC, ABS, PMMA, Transparent Plastics |

|

Texturing (Etching / EDM Texture) | Adds matte, leather-like, or patterned textures for grip or appearance. | Chemical etching, EDM, mold surface treatment | ABS, PC+ABS, PP, TPE |

|

Painting / Spray Coating | Applies decorative or protective color layers for enhanced aesthetics. | Spray coating, robotic painting lines | ABS, PC, PP, Nylon |

|

UV Coating | Increases scratch resistance and UV/weather durability. | Spray & UV curing process | PC, ABS, PMMA |

|

Laser Etching / Marking | Adds permanent logos, codes, or patterns without damaging the part. | Laser engraving systems | ABS, PC, Nylon, Metal Inserts |

|

Plating (Chrome, Nickel, etc.) | Provides metallic appearance, surface hardness, and corrosion resistance. | Electroplating or vacuum plating | ABS, PC+ABS, PBT |

|

Anodizing | Creates a corrosion-resistant and decorative oxide layer on aluminum inserts. | Electrochemical anodizing | Aluminum inserts in 2K molded parts |

|

Hot Stamping / Foil Stamping | Transfers metallic or glossy foil onto the part surface for branding or accents. | Heat and pressure stamping | ABS, PC, PP |

|

Pad Printing / Silk Screen Printing | Prints detailed graphics, texts, or logos on molded surfaces. | Pad printing machines, screen printers | ABS, PC, PP, PBT |

|

Bead Blasting | Creates a uniform matte finish to improve grip or prepare for coatings. | Sandblasting / bead blasting equipment | ABS, PC, Aluminum inserts |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

2K Injection Molding Design Guide

In this guide to 2K injection molding, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

2K Injection Molding Service FAQs

What is the minimum order quantity (MOQ) for 2K Injection Molding?

Our minimum order quantity for 2K Injection Molding depends on the complexity of the part and the materials used. Feel free to contact us for a personalized quote.

How long does it take to produce a 2K Injection Mold?

Production times typically range from 4 to 6 weeks, depending on the part complexity and tooling requirements. We’ll provide you with an accurate timeline during the quoting process.

What’s the cost of creating a custom 2K Injection Mold?

The cost depends on the design, materials, and part volume. After reviewing your specifications, we’ll provide you with a detailed cost estimate.

What are your payment terms for 2K Injection Molding orders?

We typically require a 50% deposit before production, with the balance due upon completion of the project. Specific terms can be adjusted based on your order volume and requirements.

Can you handle both small and large production runs?

Yes, we are equipped to handle both small-scale prototyping and large-volume production, providing flexible solutions for projects of all sizes.

Do you offer post-production services like assembly or packaging?

Yes, we can assist with post-production services such as part assembly, packaging, and custom labeling to streamline your supply chain.

Are You Looking for 2K Injection Molding Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.