5 Axis CNC Machining Services

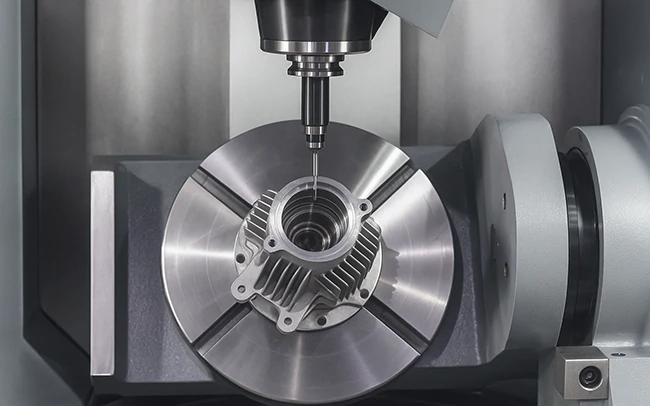

We provide advanced 5-axis CNC machining services, delivering everything from complex prototypes to precision production parts with lead times as fast as 3 days.

- Precision tolerances as tight as ±0.005 mm for metals and ±0.01 mm for plastics.

- Custom 5-axis machining for prototyping and high-volume production.

- 10K+ CNC parts made monthly

- ISO 9001:2015 Certified

Start a New 5 Axis CNC Machining Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable 5 Axis CNC Machining Services Provider from China

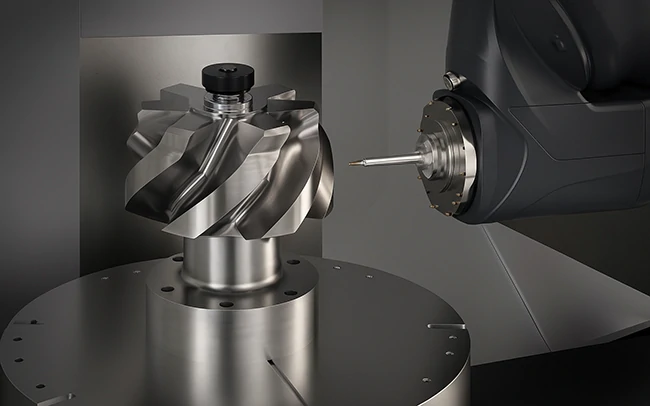

Robotika is a professional CNC machining manufacturer in China. With over a decade of manufacturing experience, Robotika serves global clients across diverse industries. Our 5-Axis CNC Machining services are designed to handle highly complex geometries, intricate curves, and multi-surface details that are difficult or impossible to achieve with conventional 3-axis or 4-axis machining. By enabling cutting on five sides of a part in a single setup, we minimize repositioning, reduce machining time, and ensure superior accuracy across critical dimensions. Our experienced engineering team offers DFM (Design for Manufacturability) feedback, material selection guidance, and process optimization to enhance part quality and production efficiency. Whether it’s a functional prototype, a complex aerospace component, or a high-aesthetic consumer product housing, our 5-axis CNC solutions deliver unmatched versatility, speed, and repeatability.

In addition to metal and plastic machining, we also take on precision plastic injection molding projects, offering a one-stop manufacturing solution for clients in automotive, aerospace, medical devices, electronics, and industrial equipment sectors. By combining cutting-edge machinery with strict quality control, we ensure every part meets international standards and exceeds customer expectations.

Our 5 Axis CNC Machining Services Capabilities

Robotika offers advanced 5-axis CNC machining services powered by high-performance 5-axis CNC machines, high-precision spindles, precision tooling & holders, and automatic tool changers (ATC). We work with various materials, including aluminum, stainless steel, titanium, brass, copper, engineering plastics (such as PEEK, ABS, Delrin, Nylon), and composite materials. We also offer a wide range of surface finishing options for our machined parts, such as anodizing, powder coating, bead blasting, polishing, electroplating, and passivation, enhancing both appearance and performance. Our machining operations can achieve tolerances as tight as ±0.005 mm for metals and ±0.01 mm for plastics, supported by strict quality inspection using automated coordinate measuring machines (CMMs) and advanced metrology tools. This ensures every part we deliver meets the most demanding dimensional accuracy and consistency standards.

5-Axis CNC Machining Capabilities

Maximum Build Size

Our up to 4000×1500×600 mm, suitable for small to medium-sized applications.

Material Compatibility

We capable of machining aluminum, stainless steel, brass, copper, carbon steel, and engineering plastics (POM, ABS, Nylon, PEEK, etc.), meeting various industrial and custom production needs.

Machining Accuracy

Our standard tolerance controlled within ±0.01mm, ensuring high precision for mechanical components, electronic parts, and industrial applications.

Surface Finishing Options

We supports anodizing, polishing, sandblasting, powder coating, electroplating, laser engraving, and more for enhanced durability and aesthetics.

Delivery Time

Our standard 5-Axis CNC machining lead time is 5-7 days, with expedited service available for urgent projects.

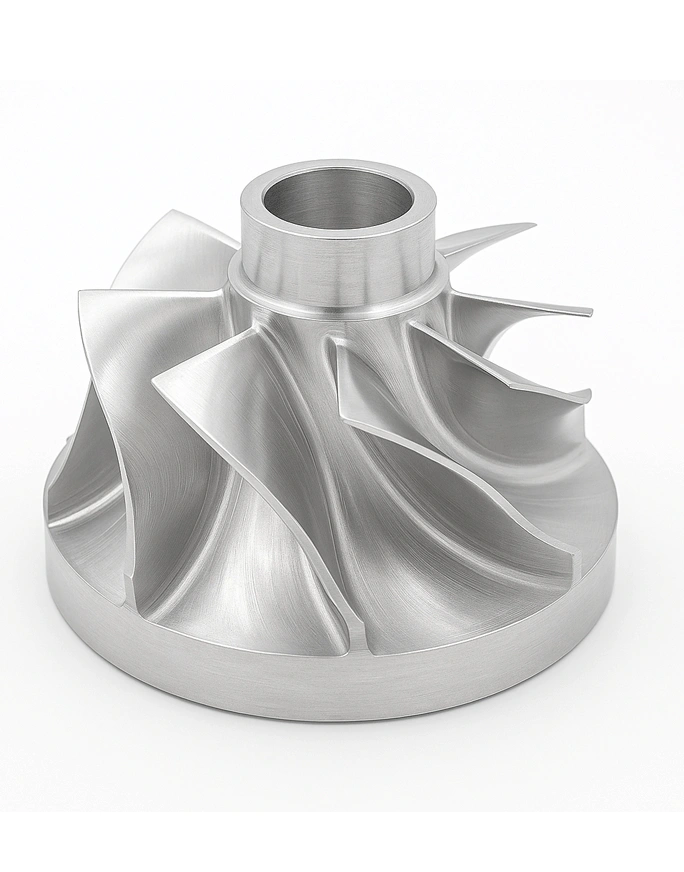

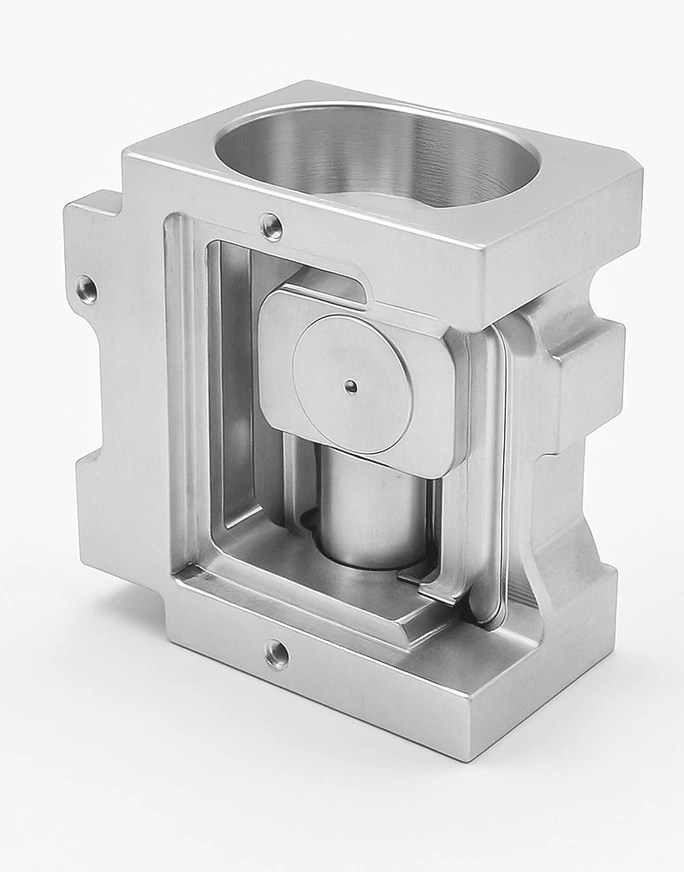

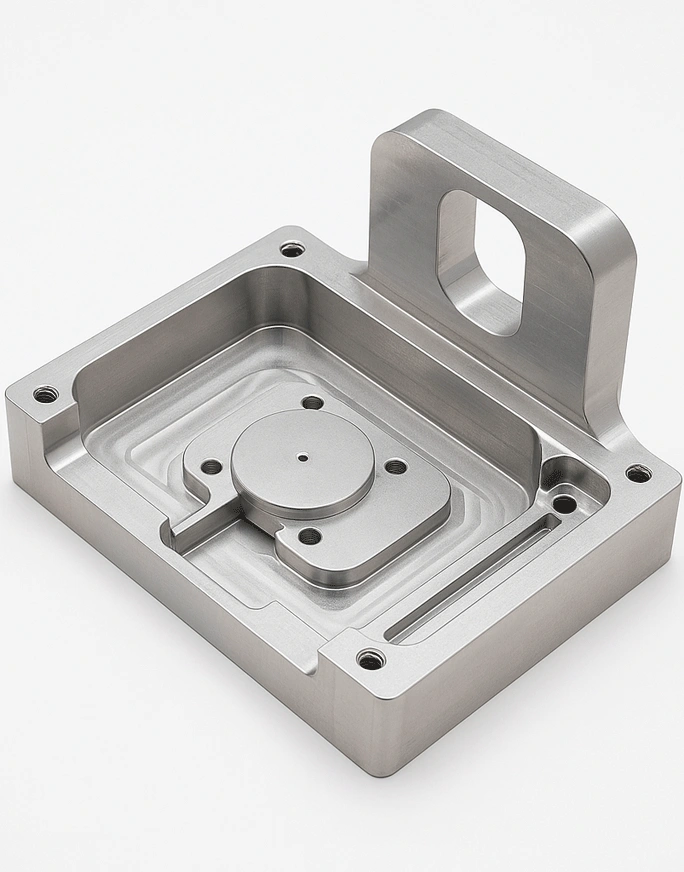

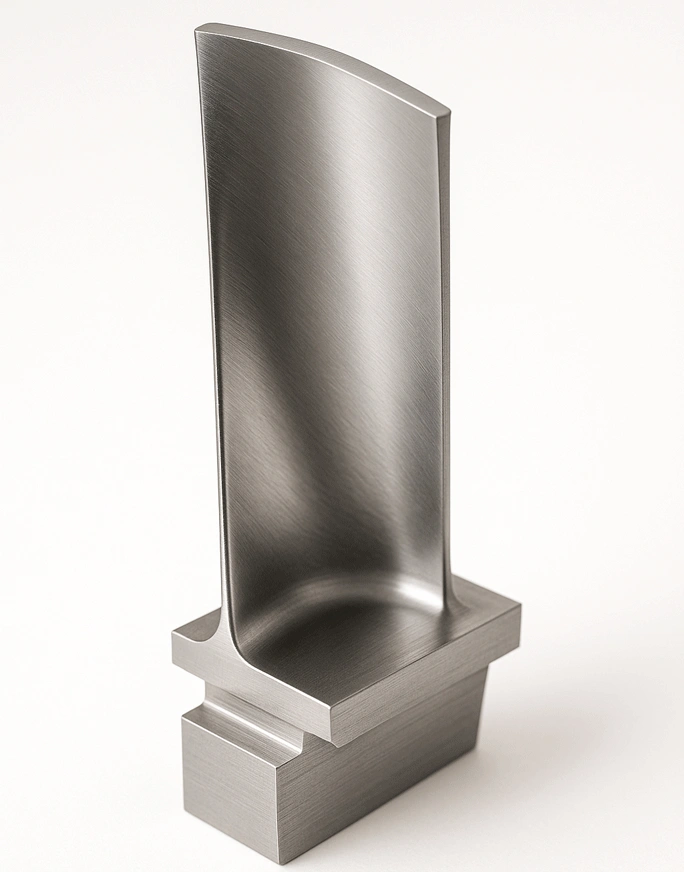

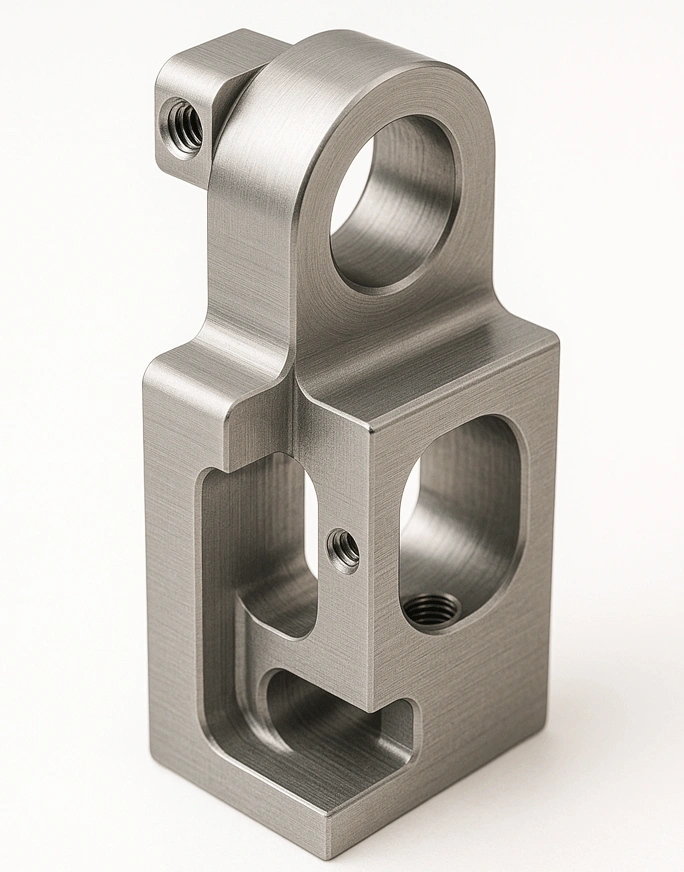

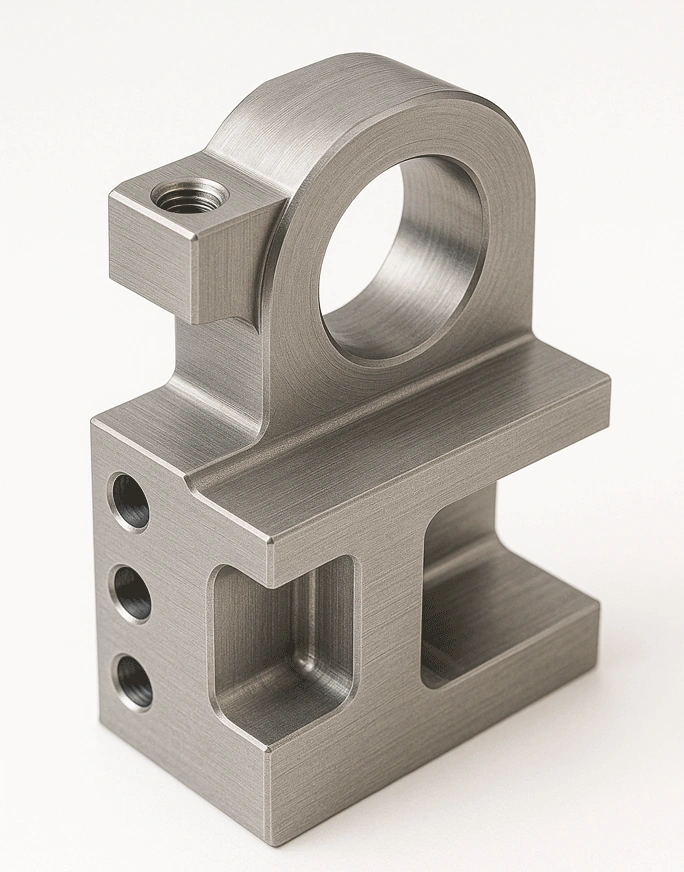

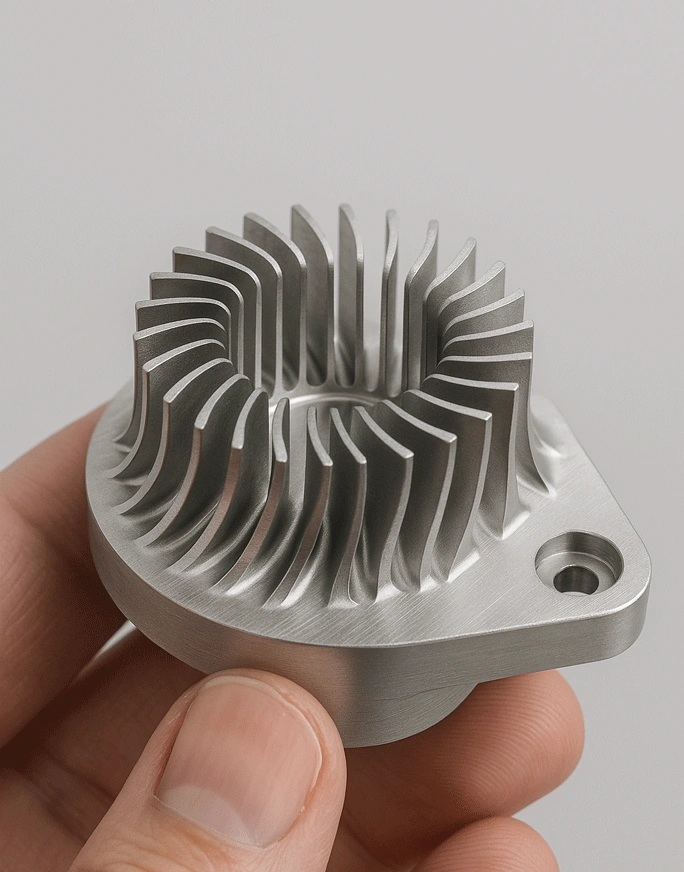

Our Latest 5-Axis CNC Machining Products We have Manufactured

Our complex geometries machined in a single setup, delivering superior accuracy, surface quality, and dimensional consistency.

5-Axis CNC Machining Tolerance

| Part Type | Tolerance Range |

|---|---|

| Aluminum Alloys | ±0.01 mm – ±0.02 mm |

| Stainless Steel | ±0.01 mm – ±0.02 mm |

| Brass / Copper | ±0.01 mm – ±0.015 mm |

| Titanium Alloys | ±0.01 mm – ±0.02 mm |

| Engineering Plastics | ±0.02 mm – ±0.05 mm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

5-Axis CNC Machining Materials

Aluminum

Aluminum is lightweight, corrosion-resistant, and offers excellent machinability, making it ideal for 5-axis CNC machining of complex geometries. It is widely used in aerospace components, automotive parts, and electronic housings. For example, 7075 aluminum is often chosen for aircraft structural parts requiring high strength.

- Mill Lead Time: As fast as 3 days

- Finishes: Anodized, bead blasted, polished.

Stainless steel

Stainless steel provides high strength, corrosion resistance, and durability, suitable for precision 5-axis CNC machining. It is used in medical devices, food processing equipment, and marine parts. For instance, 316 stainless steel is preferred for surgical instruments due to its biocompatibility.

- Mill Lead Time: 5–7 days

- Finishes: Passivated, polished, bead blasted.

Titanium

Titanium is strong, lightweight, and highly corrosion-resistant, ideal for high-performance 5-axis CNC applications. It is commonly used in aerospace, medical implants, and motorsport components. For example, Ti-6Al-4V is popular for aircraft turbine blades and bone screws.

- Mill Lead Time: 7–10 days

- Finishes: Polished, bead blasted, anodized (color).

Brass

Brass offers excellent machinability, corrosion resistance, and an attractive finish, making it perfect for decorative yet functional 5-axis CNC parts. It is often used for plumbing fittings, musical instruments, and precision gears. For example, brass CNC machining is popular for high-end valve components.

- Mill Lead Time: 3–5 days

- Finishes: Polished, nickel plated, raw.

Copper

Copper provides superior electrical and thermal conductivity, making it well-suited for specialized 5-axis CNC machining projects. It is widely used in heat exchangers, electrical contacts, and custom conductive components. For example, copper is often machined into intricate cooling plates for electronics.

- Mill Lead Time: 3–5 days

- Finishes: Polished, raw, nickel plated.

Tool Steel

Tool steel offers exceptional hardness, wear resistance, and dimensional stability, ideal for precision molds, dies, and cutting tools in 5-axis CNC machining. For instance, D2 steel is commonly used for stamping dies that require long service life.

- Mill Lead Time: 5–7 days

- Finishes: Ground, polished, heat-treated.

ABS

ABS is impact-resistant, easy to machine, and maintains good dimensional stability, making it ideal for 5-axis CNC machining of complex shapes. Commonly used in automotive dashboards, electronic housings, and appliance components due to its strength and surface quality.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, painted, polished.

PC

PC offers high impact strength, transparency, and heat resistance, perfect for 5-axis CNC machining of functional and aesthetic parts. Used in safety goggles, machine guards, and electronic device covers for its durability and clarity.

- Mill Lead Time: 3–5 days

- Finishes: Polished, frosted, painted.

PMMA

PMMA provides excellent optical clarity and weather resistance, making it suitable for precise 5-axis CNC machining of display panels, lighting covers, and signage. Often chosen for high-end retail displays and LED light diffusers.

- Mill Lead Time: 3–5 days

- Finishes: Polished, frosted.

Nylon

Nylon combines high wear resistance, toughness, and chemical stability, making it ideal for gears, bushings, and industrial parts via 5-axis CNC machining. Often used in mechanical assemblies and automotive components.

- Mill Lead Time: 3–5 days

- Finishes: Raw, polished.

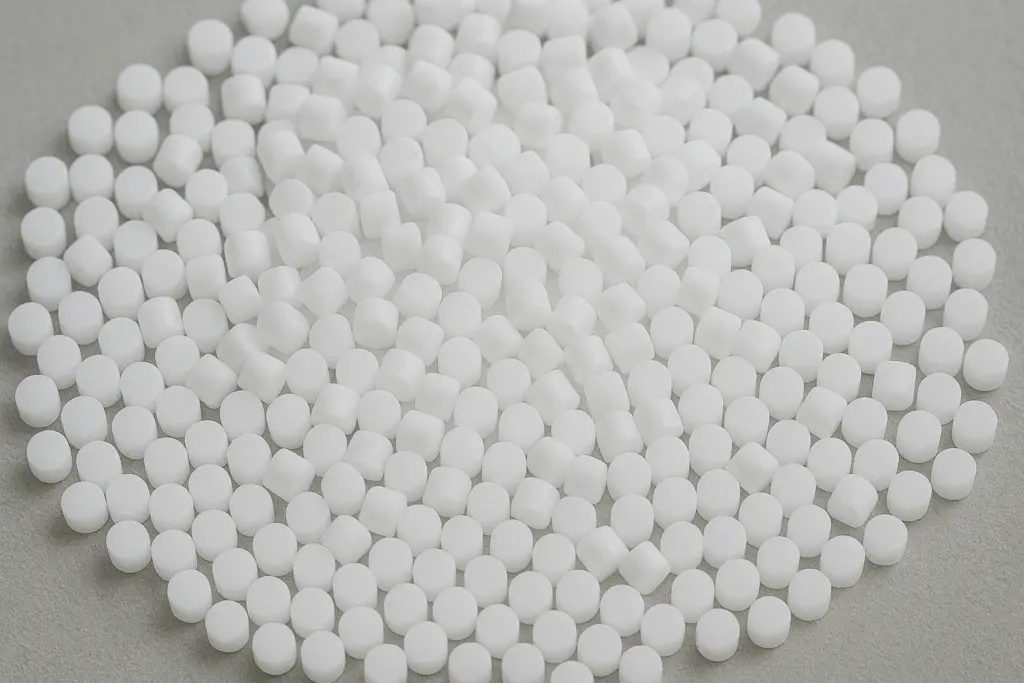

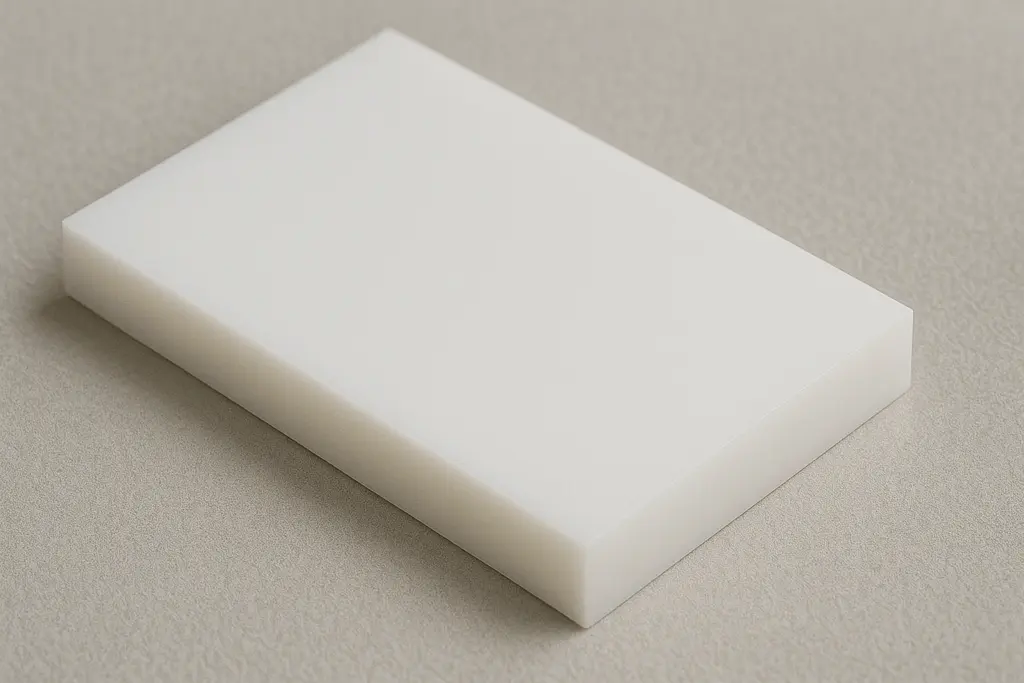

POM

POM offers excellent stiffness, low friction, and high machinability, perfect for precision 5-axis CNC parts such as bearings, rollers, and pulleys. Commonly used in conveyor systems and precision mechanical components.

- Mill Lead Time: 3–5 days

- Finishes: Raw, polished.

PEEK

PEEK has outstanding heat, chemical, and wear resistance, making it suitable for demanding 5-axis CNC applications in aerospace, medical, and electronics. Often used in surgical implants and high-performance seals.

- Mill Lead Time: 5–7 days

- Finishes: Raw, polished.

PTFE (Teflon)

PTFE has exceptional chemical resistance and low friction, perfect for 5-axis CNC machining of seals, gaskets, and non-stick components. Widely used in chemical processing equipment and food-grade applications.

- Mill Lead Time: 5–7 days

- Finishes: Raw.

PEI

PEI offers high strength, heat resistance, and dimensional stability, ideal for aerospace and automotive 5-axis CNC parts. Commonly used in aircraft interior components and electrical connectors.

- Mill Lead Time: 5–7 days

- Finishes: Raw, polished.

PVDF

PVDF combines chemical resistance, UV stability, and strength, ideal for 5-axis CNC machining of outdoor equipment and chemical handling systems. Often used in valves, fittings, and semiconductor components.

- Mill Lead Time: 5–7 days

- Finishes: Raw.

PPS

PPS offers excellent dimensional stability and high-temperature performance, making it suitable for precision 5-axis CNC parts in automotive and electronics. Used for pump components and electrical insulators.

- Mill Lead Time: 5–7 days

- Finishes: Raw.

Finishing Options for 5-Axis CNC Machining

| Name | Applicable Materials | Colors | Can Be Applied with |

|---|---|---|---|

Anodizing (Type II, Type III)

Anodizing (Type II, Type III)

|

Aluminum, Titanium | Clear, Black, Red, Blue, Gold, Custom | Aerospace brackets, automotive housings, electronic enclosures |

Powder Coating

Powder Coating

|

Aluminum, Steel, Stainless Steel | Wide range (RAL/Pantone colors) | Machinery covers, outdoor equipment, automotive parts |

Bead Blasting

Bead Blasting

|

Aluminum, Stainless Steel, Titanium | Natural matte (depends on base material) | Painting, Spray Coating |

Polishing

Polishing

|

Aluminum, Stainless Steel, Brass, Copper | Mirror-like natural metal | Consumer product housings, decorative metal parts, mold cavities |

Electroplating (Nickel, Chrome, Zinc)

Electroplating (Nickel, Chrome, Zinc)

|

Steel, Stainless Steel, Brass, Copper | Silver (Nickel/Chrome), Yellow/Silver (Zinc) | Aerospace engine parts, valve seats, precision shafts |

Passivation

Passivation

|

Stainless Steel | Natural stainless steel | Medical devices, food processing equipment, marine components |

Brushing

Brushing

|

Aluminum, Stainless Steel, Brass | Silver, Gray, Custom tones | Control panels, appliance trims, automotive interior parts |

Vapor Polishing

Vapor Polishing

|

Polycarbonate (PC), Acrylic (PMMA) | Clear, Transparent | Polycarbonate safety shields, acrylic display covers |

Black Oxide

Black Oxide

|

Carbon Steel, Alloy Steel, Stainless Steel | Black | Gears, tooling components, firearm parts |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

5-Axis CNC Machining Design Guide

In this guide to 5-axis CNC machining, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

5-Axis CNC Machining Service FAQs

What’s the typical lead time for 5-axis CNC parts?

Standard lead time is 5–7 days, but we can deliver urgent orders in as fast as 1–3 days depending on complexity.

What materials can you machine?

We work with aluminum, stainless steel, titanium, brass, copper, engineering plastics like PEEK, ABS, Delrin, and more.

Can you make both prototypes and production parts?

Yes, we handle everything from one-off prototypes to high-volume production runs.

What’s your tolerance capability?

We can achieve ±0.005 mm for metals and ±0.01 mm for plastics, verified by CMM inspection.

Do you provide finishing services?

Yes, we offer anodizing, powder coating, bead blasting, polishing, electroplating, passivation, and more.

What files do you need for a quote?

3D CAD files (STEP, IGES, or STL) and a 2D drawing with dimensions and tolerances work best.

Can you ship internationally?

Absolutely — we ship to clients worldwide via DHL, FedEx, UPS, or freight forwarders.

Are You Looking for 5-Axis CNC Machining Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.