Custom CNC Machining Services

We offer a full range of CNC machining services, delivering everything from rapid prototypes to high-quality production parts.

- Tolerances down to ±0.0002″ (0.005mm)

- Parts as Fast as one day

- 50+ Material Options

- ISO 9001:2015, IATF 16949:2016 Certified

Start a New CNC Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable CNC Machining Service Provider from China

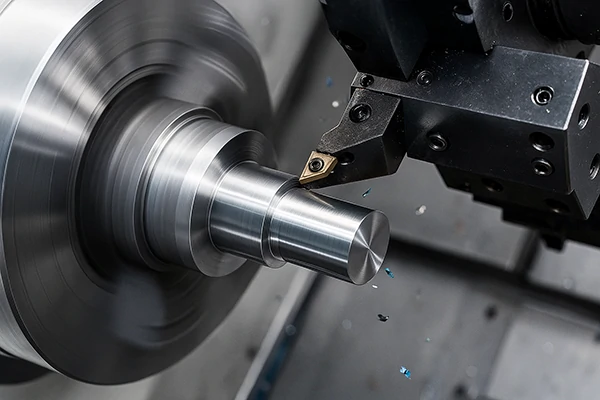

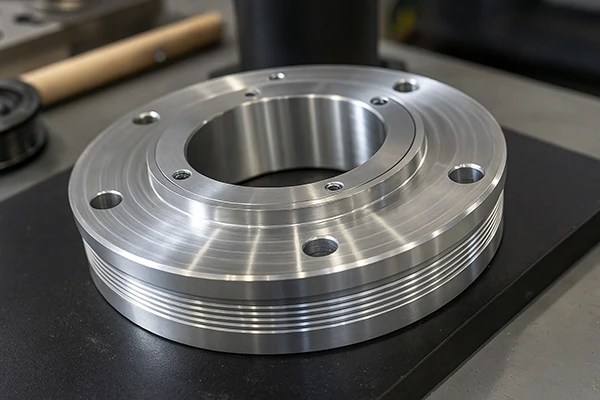

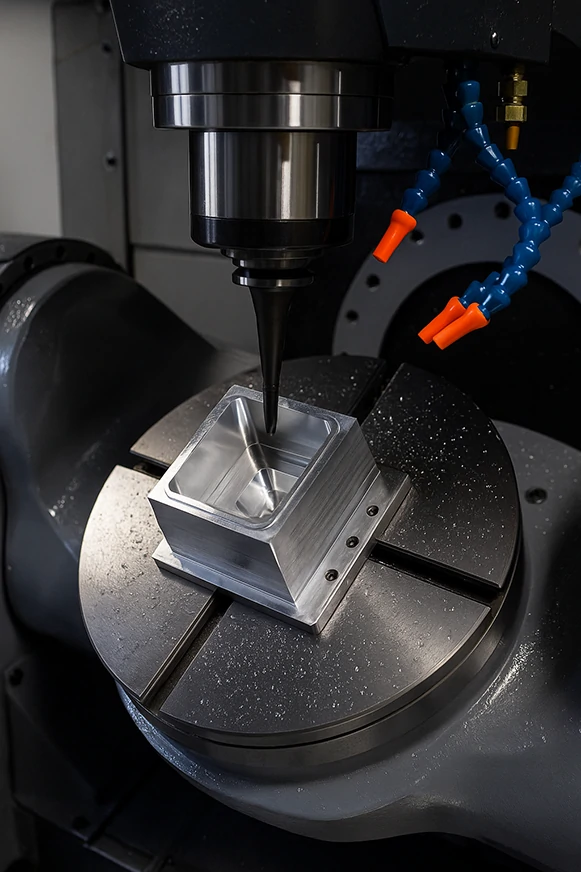

Robotika is a precision CNC machining manufacturer in China, offering rapid and reliable CNC milling and turning services for both plastic and metal components. Equipped with advanced 3-, 4-, and 5-axis machining centers, we are capable of delivering quick-turn prototypes and high-accuracy end-use parts with tight tolerances. From early-stage design to final inspection, our CNC machining services are designed to solve real-world manufacturing challenges. We provide professional DFM (Design for Manufacturability) feedback, material selection advice, and machining strategies to optimize both cost and performance.

With over 10 years of experience in CNC manufacturing, Robotika produces more than 100,000 machined parts annually for customers worldwide. Our capabilities serve a wide range of industries, including automotive, medical devices, electronics, aerospace, and industrial automation. From startups to global OEMs, clients rely on us for flexible production volumes, competitive pricing, and responsive support throughout the product development lifecycle.

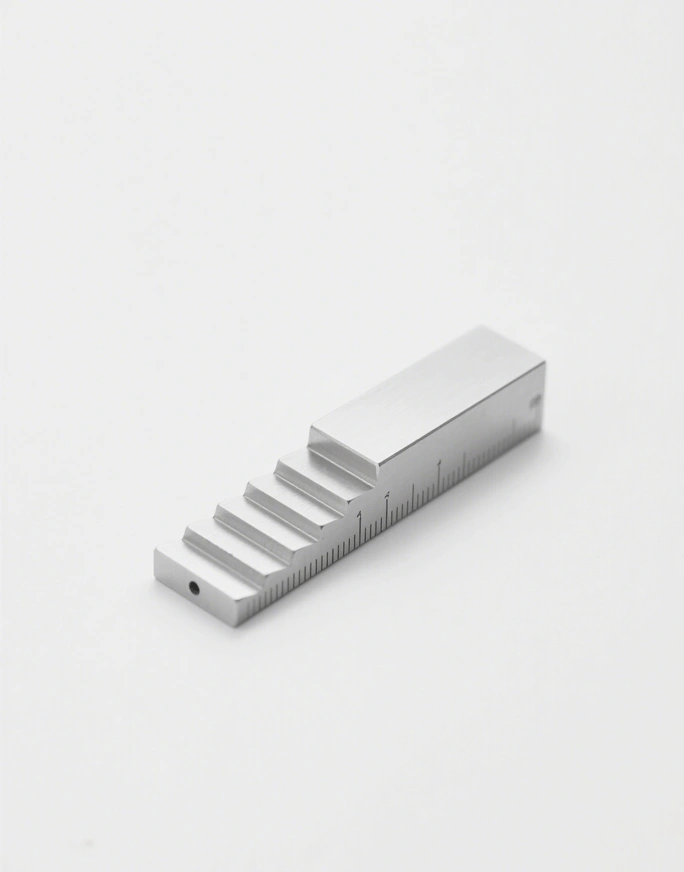

Our CNC Machining Capabilities

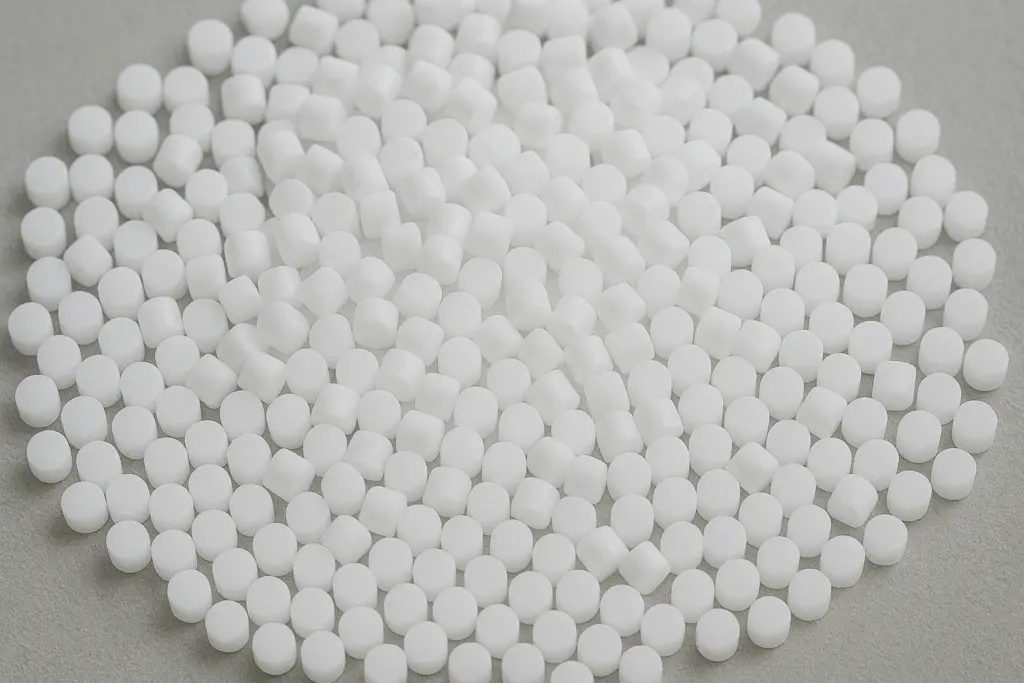

At Robotika, we offer a comprehensive suite of CNC machining technologies, including CNC milling, CNC turning, turn-mill compound machining, electrical discharge machining (EDM), and wire-cut machining. We work with a wide range of metals and plastics, including aluminum, stainless steel, carbon steel, brass, copper, titanium, POM, ABS, PC, PEEK, and other engineering-grade materials. Additionally, Robotika offers a variety of surface treatment options such as anodizing, powder coating, sandblasting, polishing, electroplating, black oxide, and laser engraving.

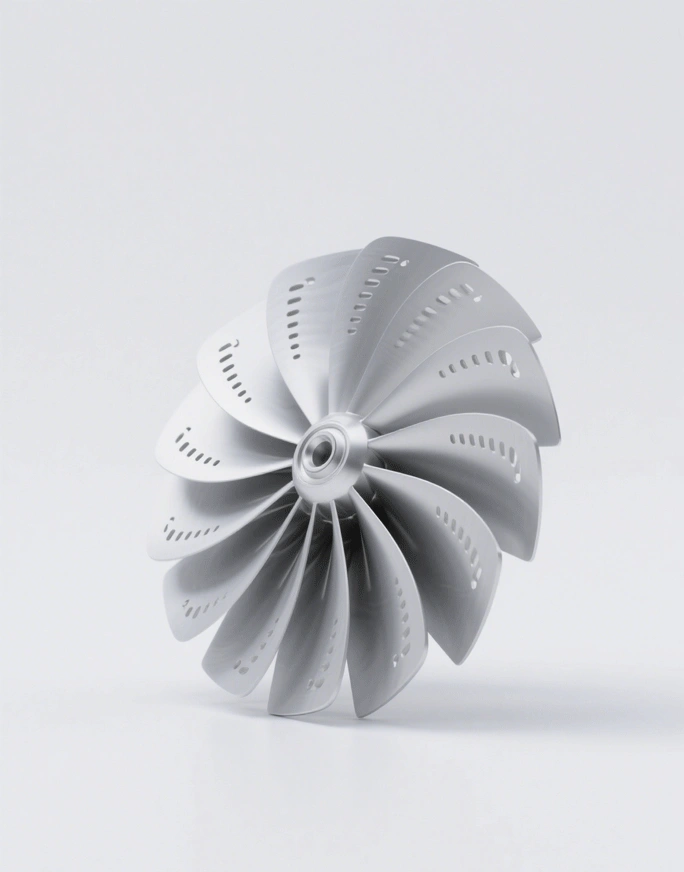

Our turning-milling compound machining combines the advantages of CNC turning and milling in a single setup, enabling efficient production of complex, multi-featured parts.

Rapid prototyping with CNC machining delivers precision, speed, and flexibility to accelerate your product launch.

Precision finishing enhances appearance and durability, delivering smooth, protective surfaces for high-performance CNC parts.

CNC Machining Capabilities

Part Size

2000 mm x 1500 mm x 600 mm

Minimum Wall Thickness

0.8 mm (metals), 1.5 mm (plastics)

Minimum Feature Size

0.5 mm or Ø 0.50 mm

Minimum Cutting Depth

0.3 mm

Cavity Depth

4x width (w)

As Machined Finish

Ra 125 or better

Undercut Width (T-slot)

3-40 mm

Complex Features

Curved surfaces, undercuts, deep cavities, grooves, complex contours, asymmetrical features, etc.

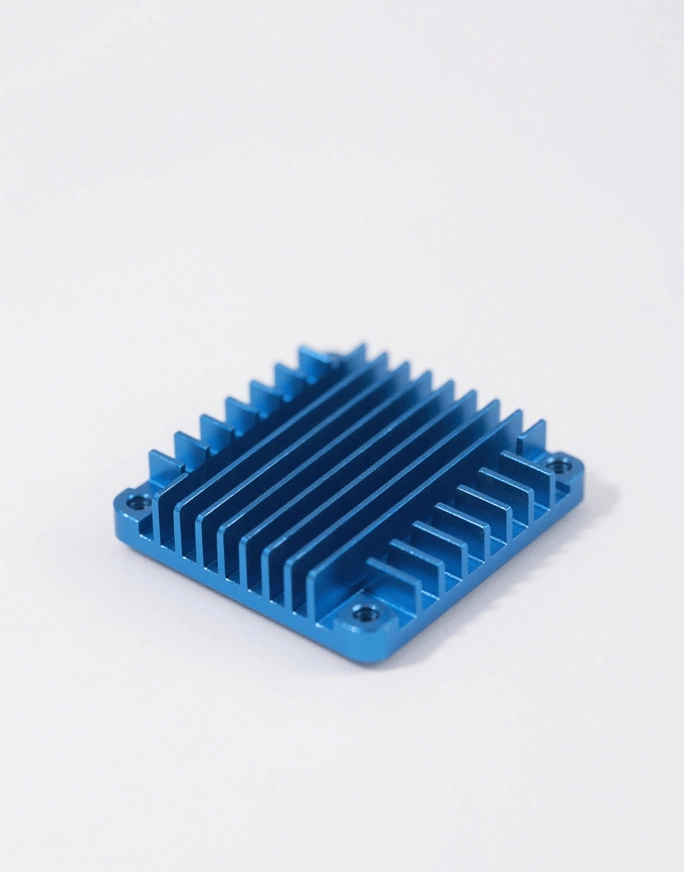

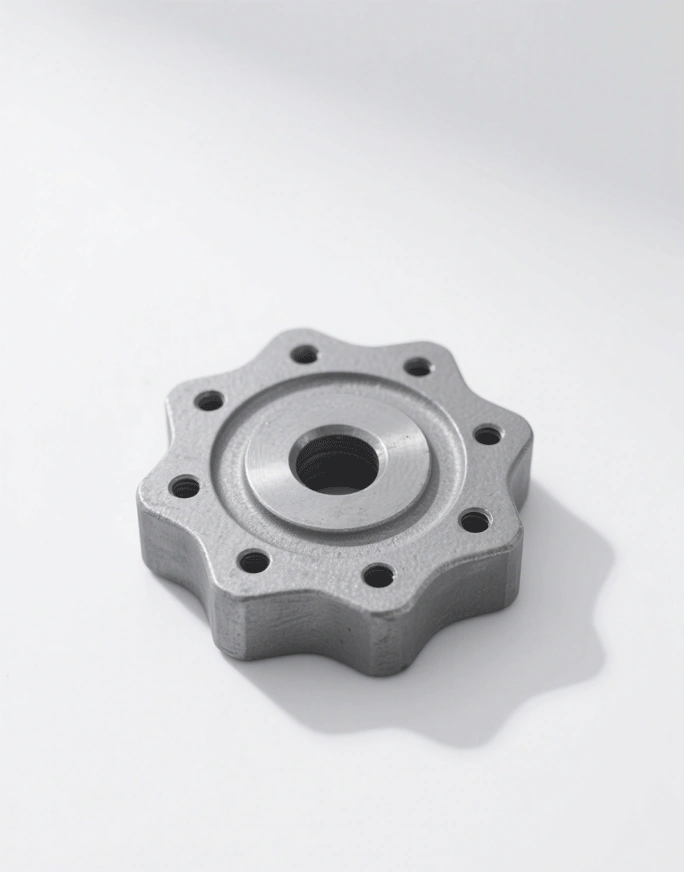

Our Latest CNC Machined Products We have Manufactured

CNC Machining Tolerance

| Name | Metals, PEEK, And ULTEM with Drawing | Other Plastics with Drawing | No Drawing |

|---|---|---|---|

| Linear Dimension | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.05 mm +/- 0.002 inch | ISO 2768 Medium |

| Hole Diameters (Not Reamed) | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.05 mm +/- 0.002 inch | ISO 2768 Medium |

| Shaft Diameters | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.05 mm +/- 0.002 inch | ISO 2768 Medium |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

CNC Machining Materials

Aluminum

Aluminum is a lightweight, high-strength metal widely used in CNC machining for its excellent machinability, corrosion resistance, and thermal conductivity. Its common sizes are 6061, 7075, 5052, and 2024. It is ideal for aerospace, automotive, and electronics applications due to its durability and low density. Aluminum can also be anodized for enhanced surface hardness and aesthetics. Its versatility and cost-effectiveness make it a top choice for precision-engineered components.

• Mill Lead Time: As fast as 3 days

• Finishes: Raw, anodized, bead blasted, polished

Stainless Steel

Stainless steel is a high-strength, corrosion-resistant metal commonly used in CNC machining for its durability and excellent mechanical properties. Its common grades include 304, 316, and 410, each offering varying levels of strength, heat resistance, and anti-corrosion performance. Ideal for medical, aerospace, and industrial applications, stainless steel provides superior wear resistance and can withstand extreme environments. It is also compatible with various surface finishes, including polishing and passivation, to enhance its performance and aesthetics.

• Mill Lead Time: As fast as 5 days

• Finishes: Raw, polished, passivated, bead blasted

Carbon Steel

Carbon Steel is highly suitable for CNC machining due to its excellent strength, hardness, and machinability. It provides superior wear resistance and dimensional stability, making it ideal for structural and mechanical parts. Common applications include gears, shafts, fixtures, and industrial tooling, where durability and load-bearing capacity are essential.

• Mill Lead Time: As fast as 5 days

• Finishes: Raw, black oxide, zinc plated, polished

Alloy Steel

Alloy Steel is ideal for CNC machining due to its excellent strength, toughness, and wear resistance. It maintains high-dimensional stability even under heavy loads, making it perfect for precision engineering. Common applications include gears, shafts, automotive components, and machine bases that demand both strength and durability.

• Mill Lead Time: As fast as 5 days

• Finishes: Raw, black oxide, zinc plated, polished

Brass & Copper

Brass & Copper are highly machinable metals widely used in CNC machining for their excellent conductivity, corrosion resistance, and aesthetic appeal. Brass (C360, C464) is known for its low friction and antimicrobial properties, making it ideal for fittings, valves, and decorative parts. Copper (C110) offers exceptional electrical and thermal conductivity, making it a top choice for electrical components and heat exchangers. Both materials provide superior durability and can be polished or plated for enhanced performance and appearance.

• Mill Lead Time: As fast as 5 days

• Finishes: Raw, polished, nickel-plated, gold-plated

Titanium

Titanium is a high-strength, lightweight, and corrosion-resistant metal widely used in CNC machining for its exceptional durability and biocompatibility. Common grades include Grade 2 and Grade 5 (Ti-6Al-4V), offering a balance of strength and machinability. Titanium is ideal for aerospace, medical implants, and high-performance automotive parts, where weight reduction and extreme durability are critical. It also withstands high temperatures and harsh environments, making it suitable for demanding applications.

• Mill Lead Time: As fast as 7 days

• Finishes: Raw, bead blasted, polished, anodized

ABS

ABS (Acrylonitrile Butadiene Styrene) is a versatile and cost-effective thermoplastic widely used in CNC machining for its impact resistance, durability, and heat tolerance. Known for its excellent machinability and strength, ABS is a top choice for automotive, consumer electronics, and prototyping applications. It can be easily modified with additives to enhance flame retardancy, UV resistance, or surface hardness, making it adaptable to various industrial needs.

• Mill Lead Time: As fast as 3 days

• Color: Black, neutral matte finish

PC

PC (Polycarbonate) is a high-strength, impact-resistant thermoplastic widely used in CNC machining for its exceptional durability, heat resistance, and optical clarity. Known for its excellent mechanical properties, PC is ideal for automotive, aerospace, and electronic applications, including protective covers and lenses. It offers superior toughness and transparency, making it a great alternative to glass. Additionally, PC can be enhanced with additives for improved UV resistance and flame retardancy, expanding its industrial applications.

• Mill Lead Time: As fast as 3 days

• Colors: Transparent, black, neutral matte finish

POM

POM (Polyoxymethylene, Delrin®) is a high-strength, low-friction thermoplastic widely used in CNC machining for its excellent wear resistance, stiffness, and dimensional stability. Known for its low moisture absorption and high machinability, POM is ideal for gears, bearings, bushings, and mechanical components in automotive, industrial, and consumer applications. It offers good chemical resistance and retains its mechanical properties even in demanding environments, making it a reliable choice for precision parts.

• Mill Lead Time: As fast as 3 days

• Colors: Black, white, neutral matte finish

PMMA

PMMA (Polymethyl Methacrylate, Acrylic) is a transparent, lightweight thermoplastic widely used in CNC machining for its optical clarity, UV resistance, and weather durability. Known for its high impact strength and excellent machinability, PMMA is an ideal choice for display panels, lighting components, lenses, and protective covers. It offers superior scratch resistance compared to polycarbonate and can be polished to achieve a glass-like finish, making it a popular alternative to glass in various applications.

• Mill Lead Time: As fast as 3 days

• Colors: Transparent, black, neutral matte finish

PEEK

PEEK (Polyether Ether Ketone) is a high-performance engineering thermoplastic widely used in CNC machining for its exceptional strength, heat resistance (up to 260°C), and chemical resistance. Known for its superior mechanical properties, PEEK is ideal for aerospace, medical, and automotive applications, including structural components and high-wear parts. It offers excellent dimensional stability and biocompatibility, making it a top choice for demanding environments where durability and performance are critical.

• Mill Lead Time: As fast as 5 days

• Colors: Natural (beige), black

PTFE

PTFE (Polytetrafluoroethylene, Teflon®) is a high-performance thermoplastic widely used in CNC machining for its exceptional chemical resistance, low friction, and high-temperature tolerance (up to 260°C). Known for its non-stick properties and electrical insulation, PTFE is ideal for seals, gaskets, insulators, and medical components. It maintains stability in extreme environments, making it a preferred material for aerospace, chemical processing, and food-grade applications.

• Mill Lead Time: As fast as 5 days

• Colors: White, black

PEI

PEI (Polyetherimide, Ultem®) is a high-performance thermoplastic widely used in CNC machining for its exceptional heat resistance (up to 217°C), flame retardancy, and mechanical strength. Known for its dimensional stability and excellent electrical insulation, PEI is ideal for aerospace, medical, and electronic applications requiring high-performance materials. It also offers good chemical resistance and maintains strength under extreme conditions, making it a reliable choice for demanding environments.

• Mill Lead Time: As fast as 5 days

• Colors: Amber, black

Nylon

Nylon (Polyamide, PA) is a strong, durable thermoplastic widely used in CNC machining for its high wear resistance, toughness, and chemical stability. Known for its low friction and excellent mechanical properties, Nylon is ideal for gears, bearings, bushings, and structural components in automotive, industrial, and consumer applications. It can absorb moisture, which affects its dimensional stability, but additives can improve its performance for specific uses.

• Mill Lead Time: As fast as 3 days

• Colors: Natural (off-white), black

Finishing Options for CNC Machining

| Name | Applicable Materials | Colors | Application | |

|---|---|---|---|---|

|

Chem Film | Aluminum | Clear, gold | Media Blasting, Tumbling, Type II Anodizing* Type III Anodizing with PTFE* |

|

Anodizing | Aluminum | Clear, black, grey, red, blue, gold | Media Blasting, Tumbling, Chem film* |

|

Black Oxide | Steel, Stainless Steel | Black | Media Blasting, Tumbling, Passivation |

|

Electroless Nickel Plating | Aluminum, Steel, Stainless Steel | — | Media Blasting, Tumbling |

|

Electropolishing | Steel, Stainless Steel | — | — |

|

Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | — | All post processes, except Electropolish and Powder Coat |

|

Nickel Plating | Aluminum, Steel, Stainless Steel | — | Media Blasting, Tumbling |

|

Passivation | Steel, Stainless Steel | — | Black Oxide, Electroless Nickel Plating, Zinc Plating, Tumbling, Media Blasting |

|

Powder Coating Services | Aluminum, Steel, Stainless Steel | Full Pantone or RAL color catalog | — |

|

Tumbling | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | — | All post processes, except Electropolish and Powder Coat |

|

Vapor Polishing | CNC Polycarbonate (Clear, Black) | — | Enhanced Cosmetic Appearance, Near Optically Clear Applications |

|

Zinc Plating | Steel, Stainless Steel | Clear (light blue coating). Black (glossy black coating). | Media Blasting, Tumbling, Passivation |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

CNC Machining Design Guide

In this guide to CNC machining, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

CNC Machining Service FAQs

What CAD type do you accept?

We accept native SolidWorks (.sldprt) and ProE (.prt) files, as well as solid 3D CAD models in IGES (.igs), STEP (.stp), ACIS (.sat), and Parasolid (.x_t or .x_b) formats. .stl files are also supported, but two-dimensional (2D) drawings are not accepted.

How do I get a quote?

Send us CAD files (such as STEP format), and tell us the quantity, material, surface finish, color, or other requirements you need, then we will check and evaluate, and give you a suggestion for the part design and quote you.

Does Robotika offer finishing options and secondary operations?

Yes, our services include a variety of enhanced finishing and secondary processing options, including injection molding, CNC machining, 3D printing, and sheet metal processing.

Who owns the mold?

Our customer! Mold belongs to our customer property, it will only be used to produce plastic parts for you, and handled by you.

Can the mold be modified after the first run?

Yes, if you are not satisfied with T1 samples and want to change some structures, just provide a newly changed CAD file, then we will check again, and tell you some necessary mold modification cost.

Can different parts be made in one mold?

Yes, it is called a family mold. If these parts are the same color, material, it is a good way to reduce the mold cost and make these parts in one mold.

Do you provide First Article Inspection (FAI) services?

Yes, we provide First Article Inspection (FAI) services for machined and molded parts.

CNC Machining Related Resource

Are You Looking for CNC Machining Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.