Custom Vacuum Casting Services

We support comprehensive vacuum casting services, from rapid prototyping to low-volume production runs. Fastest delivery in 5 days.

- Achieve tolerances as precise as ±0.05 mm

- Typically 10 business days for initial prototypes

- Variety of color options and surface finishes

- ISO 9001:2015 Certified

Start a New Vacuum Casting Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable Vacuum Casting Services Supplier from China

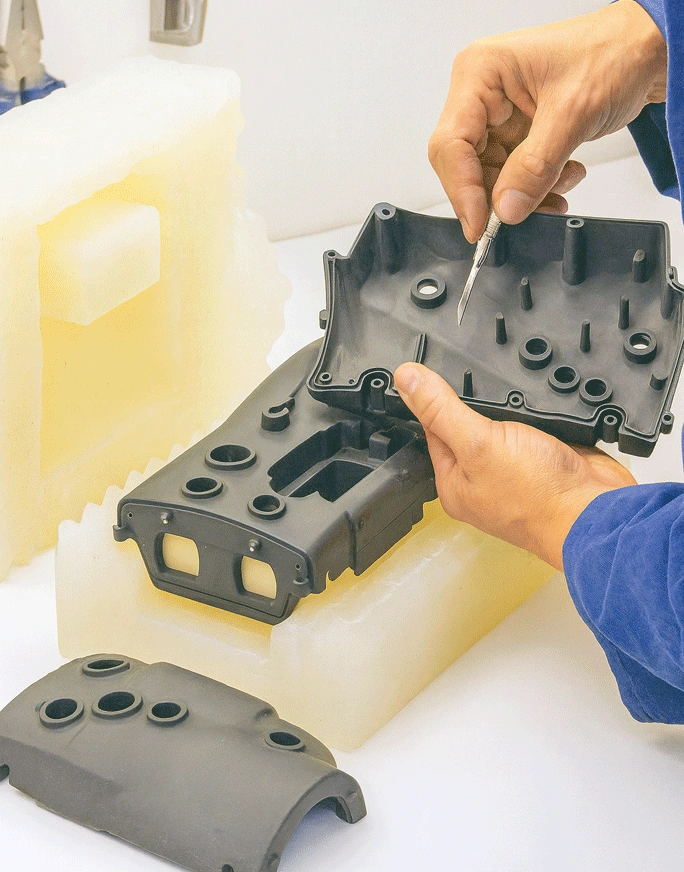

Robotika has been an expert in precision plastics manufacturing for a decade. We produces rapid prototypes and low-volume production parts for clients worldwide. Our vacuum casting process allows us to create detailed, functional prototypes with a high degree of accuracy and surface finish. By leveraging our in-house expertise and capabilities, we help clients avoid costly production delays and design errors, ensuring the final product meets functional and aesthetic expectations. We work closely with each client to understand their specific needs, offering value-added services such as material selection, post-processing, and fast turnaround times.

Our capabilities support a wide range of industries, including automotive, electronics, medical, aerospace, and consumer products. Our team of engineers, designers, and technicians work collaboratively to support our customers throughout the entire production process, from prototype to final product, ensuring the highest level of quality and satisfaction.

Our Vacuum Casting Services Capabilities

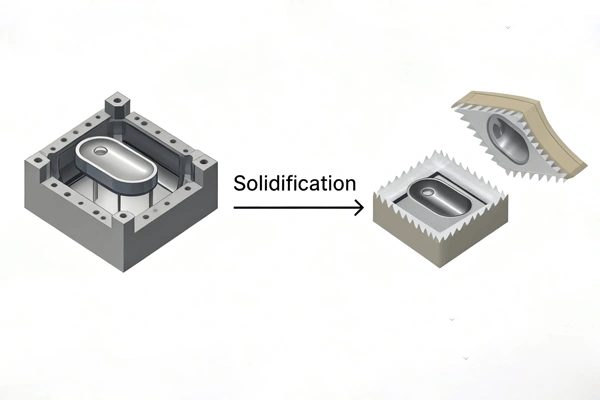

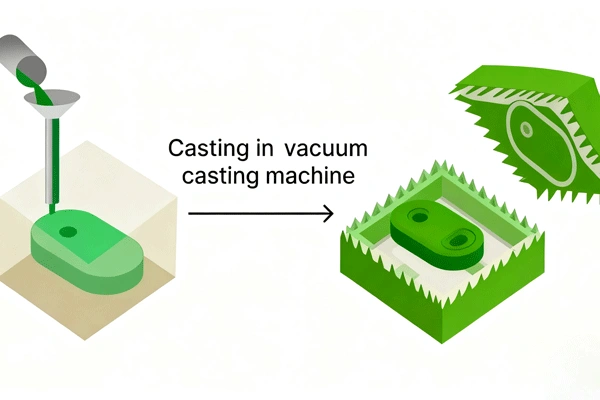

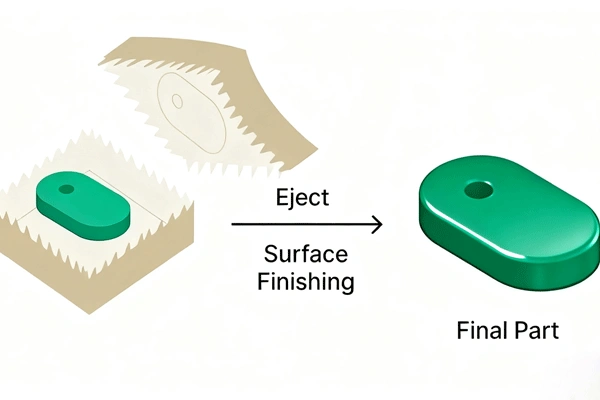

Robotika offers comprehensive solutions that include Master Model Creation, Mold Making, Casting, Demolding and Finishing. We use a wide range of materials such as polyurethane, silicone, rubber, and other elastomers. These materials are carefully selected to meet the functional and aesthetic needs of industries including automotive, medical, and consumer products. We also provide a variety of surface treatment options, including sanding, polishing, painting, and coating. Our vacuum casting operations achieve dimensional tolerances as tight as ±0.1 mm, ensuring consistency and accuracy across all parts. Each piece undergoes rigorous quality control, with advanced inspection tools like automated coordinate measuring machines (CMMs) and 3D scanners, to guarantee high-quality and defect-free production.

Deliver custom, high-precision molds that ensure optimal performance and durability, allowing for seamless production of high-quality parts in low-volume or rapid prototyping runs.

Utilize advanced vacuum casting technology to produce highly accurate and detailed parts with superior surface finishes, ensuring quick turnaround and exceptional quality for both prototypes and production runs.

Ensure a smooth, flawless finish by carefully removing parts from molds and applying expert post-processing techniques, including sanding, polishing, and painting, to deliver high-quality, ready-to-use components.

Vacuum Casting Capabilities

Maximum Build Size

Up to 750mm in length, with customizable width and height based on part requirements.

Material Compatibility

We use a variety of materials, including polyurethane, silicone, and rubber, meeting diverse industrial and custom production needs.

Molding Precision

Our standard tolerance is controlled within ±0.05mm, ensuring high precision for lightweight and durable plastic components.

Color and Surface Finishing Options

We support variety of color options and surface finishes, including standard colors, metallic finishes, and custom Pantone options.

Delivery Time

Our standard injection molding lead time is 5-10 days, with expedited services available for urgent projects.

Our Latest Vacuum Casting Products We have Manufactured

Vacuum Casting Tolerance

| Part Type | Tolerance Range |

|---|---|

| Tolerance Range | +/- 0.5 mm to +/- 1.0 mm |

| Precision Die Castings | +/- 0.2 mm to +/- 0.5 mm |

| Complex Vacuum Castings | +/- 1.0 mm to +/- 2.0 mm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

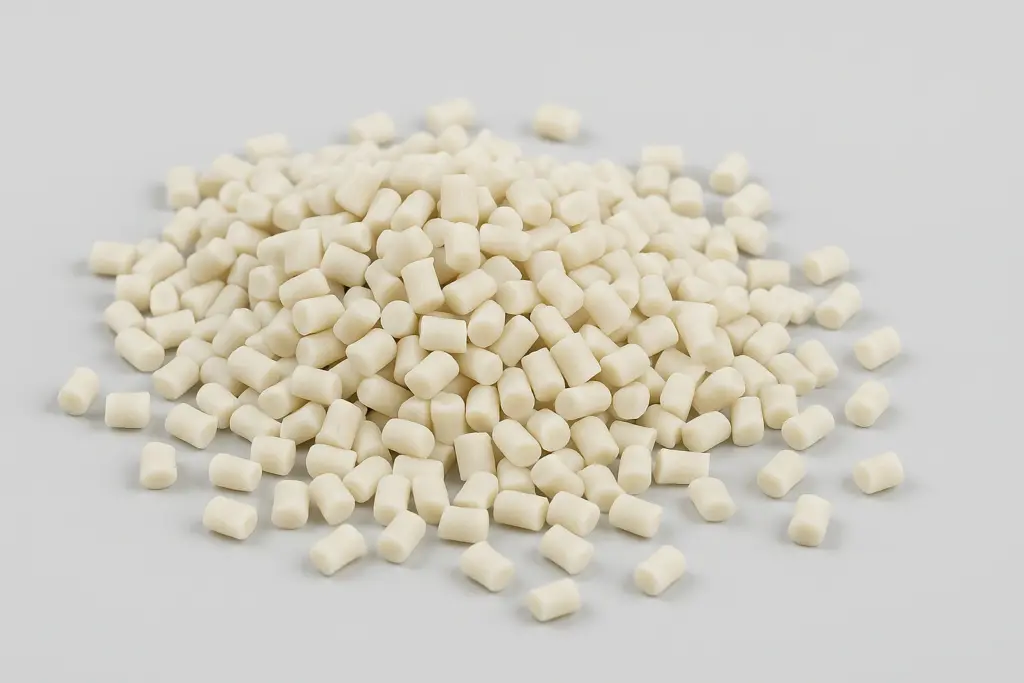

Vacuum Casting Materials

ABS (Acrylonitrile-Butadiene-Styrene)

ABS is one of the most popular materials for Vacuum Casting Services because it offers a strong balance of toughness, rigidity, and good surface finish. It is especially suitable for functional prototypes and small-batch production where parts need to replicate the performance of injection-molded plastics. Vacuum-cast ABS parts are often used in automotive components, electronic housings, and household appliance prototypes. For example, dashboards, connectors, and consumer electronics shells can be cast in ABS to verify both mechanical performance and aesthetic requirements before moving to large-scale injection molding.

Mill Lead Time: As fast as 4–5 days

Finishes: Raw, painted, textured, polished

PP (Polypropylene)

Polypropylene is widely used in Vacuum Casting Services because of its excellent chemical resistance, fatigue strength, and flexibility. It is ideal for prototypes that require living hinges, snap-fit features, or lightweight but durable parts. PP vacuum-cast components are commonly found in packaging prototypes, automotive trims, and consumer product housings where repeated use and resilience are important. For instance, food container lids, automotive interior clips, or medical device casings can be effectively replicated in vacuum-cast PP to ensure cost-effective testing and small-batch production runs.

Mill Lead Time: As fast as 4–6 days

Finishes: Raw, polished, textured

PE (Polyethylene)

Polyethylene is suitable for Vacuum Casting Services thanks to its outstanding impact resistance, chemical stability, and excellent flexibility. It is widely used in the development of containers, protective covers, and packaging prototypes where toughness and cost efficiency are critical. PE vacuum-cast parts are also valued for their ability to withstand rough handling, making them ideal for field testing in industrial equipment, logistics products, or outdoor applications. For example, prototype fuel containers, protective caps, or household storage items are often cast in PE to validate design and durability before scaling up.

Mill Lead Time: As fast as 4–6 days

Finishes: Raw, polished, painted

PMMA (Acrylic)

PMMA, or acrylic, is highly valued in Vacuum Casting Services for its excellent optical clarity, rigidity, and ability to replicate glossy finishes. It is the preferred choice for transparent prototypes where appearance and light transmission are critical, such as lenses, lighting covers, and display windows. For example, vacuum-cast PMMA is frequently used in automotive light guides, consumer electronic screens, and medical device viewports. Its ability to achieve high-quality transparent or tinted finishes allows companies to validate both functional and aesthetic requirements for end-use parts.

Mill Lead Time: As fast as 5–7 days

Finishes: Clear polished, frosted, tinted, painted

Nylon (Polyamide, PA)

Nylon is an excellent choice for Vacuum Casting Services because of its high strength, toughness, and wear resistance. It is often selected for functional prototypes that require moving parts, mechanical strength, or friction resistance. Vacuum-cast nylon parts are widely used in gears, clips, handles, and industrial equipment prototypes. For instance, small-batch production of automotive engine components, consumer product hinges, or mechanical fixtures can be effectively achieved with nylon casting, allowing engineers to test real-world performance before committing to full-scale manufacturing.

Mill Lead Time: As fast as 5–7 days

Finishes: Raw, polished, painted, textured

PC (Polycarbonate)

Polycarbonate is an excellent material for Vacuum Casting Services thanks to its superior impact resistance, dimensional stability, and optical clarity. It is particularly useful for prototypes that require transparent or semi-transparent properties with added toughness. Vacuum-cast PC is widely used in automotive lighting components, safety covers, medical device housings, and electronic displays. For example, clear protective shields or transparent casings for electronics can be replicated in PC to test durability and optical performance. This makes it ideal for industries that demand both mechanical strength and high-quality appearance in low-volume production.

Mill Lead Time: As fast as 5–7 days

Finishes: Clear polished, frosted, tinted, painted

PBT (Polybutylene Terephthalate)

PBT is a strong engineering plastic often applied in Vacuum Casting Services for parts requiring heat resistance, dimensional stability, and excellent electrical insulation. It is frequently chosen for prototypes in the automotive and electronics sectors where durability and resistance to wear are essential. Vacuum-cast PBT parts are used in applications such as electrical connectors, sensor housings, and structural components. For example, automotive electrical junction boxes or consumer electronic parts can be replicated with PBT to validate real-world performance. Its combination of toughness and stability makes it a reliable material for functional prototypes.

Mill Lead Time: As fast as 5–7 days

Finishes: Raw, painted, polished, textured

TPU (Thermoplastic Polyurethane)

TPU is highly valued in Vacuum Casting Services for its excellent elasticity, abrasion resistance, and ability to mimic rubber-like flexibility. It is the go-to choice for prototypes that require durability combined with softness and flexibility. Common applications include seals, gaskets, overmold grips, and wearable product prototypes. For instance, TPU is often vacuum-cast into protective smartphone cases, medical device grips, or industrial seals to validate ergonomic comfort and performance under stress. Its balance of toughness and elasticity makes TPU ideal for consumer, medical, and industrial testing in low-volume runs.

Mill Lead Time: As fast as 5–6 days

Finishes: Raw, rubber-like textured, polished

Heat-Resistant PU

Specialized heat-resistant polyurethane formulations are often used in Vacuum Casting Services to replicate the properties of high-performance plastics such as PPS or PEEK. These materials are designed for prototypes that must withstand higher operating temperatures while maintaining dimensional accuracy and mechanical integrity. Typical applications include under-the-hood automotive parts, aerospace testing components, and industrial equipment housings. For example, small-batch production of heat-resistant clips, fixtures, or casings can be achieved using these PU grades, allowing engineers to evaluate thermal stability before committing to expensive tooling and full-scale production.

Mill Lead Time: As fast as 6–8 days

Finishes: Raw, polished, painted

Finishing Options for Vacuum Casting

| Name | Applicable Materials | Colors | Can Be Applied with |

|---|---|---|---|

Painting / Spray Coating

Painting / Spray Coating

|

PU, ABS, PC, Nylon | Any color (customizable) | Primer, Base Coat, Clear Coat |

Polishing

Polishing

|

PU, PMMA, PC, ABS | Transparent, Natural, Glossy | Sanding, Buffing, Clear Coating |

Sandblasting

Sandblasting

|

PU, ABS, Nylon | Natural or Light Gray (matte) | Painting, Texturing |

Texturing

Texturing

|

PU, ABS, Nylon | Matte, Satin, Natural | Sandblasting, Painting |

Tumbling

Tumbling

|

Resins, Plastics | Natural material color | Abrasive media, Vibratory tumblers |

Clear Coating

Clear Coating

|

PU, ABS, PMMA, PC | Transparent (Glossy / Matte) | Painting, Polishing |

Vacuum Metallization

Vacuum Metallization

|

PU, ABS, PC | Chrome, Gold, Silver, Custom | Vacuum chamber, Metal vapor deposition |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Vacuum Casting Design Guide

In this guide to vacuum casting, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

Vacuum Casting Service FAQs

What’s the lead time for vacuum casting?

We typically deliver your parts in 5 to 10 days, depending on complexity and quantity. Rush orders can be accommodated for faster turnaround.

What materials do you use for vacuum casting?

We offer a variety of materials, including polyurethane, silicone, and rubber, tailored to your product’s specific needs for durability and flexibility.

Can you create custom molds for my design?

Yes, we provide custom mold making services, ensuring each mold is designed precisely to replicate your design with accuracy and high-quality results.

What tolerances can you achieve with vacuum casting?

Our vacuum casting process can achieve tolerances as tight as ±0.1 mm, ensuring consistency and precision in every part.

Do you offer surface finishing options for cast parts?

Absolutely! We offer surface treatments like sanding, polishing, painting, and coating to give your parts a professional, ready-to-use finish.

What’s the minimum order quantity for vacuum casting?

We specialize in both low-volume and small-batch orders, with no minimum required for prototypes or small production runs.

Can you handle complex designs?

Yes, we’re equipped to handle complex designs, ensuring that intricate details are captured with precision in the casting process.

Vacuum Casting Related Resource

Looking for Vacuum Casting Manufacturer in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.