Custom Insert Injection Molding Services

Robotika provides insert injection molding service with high-quality, cost-effective solutions tailored to your specific needs. Delivery is as fast as 7 days.

- Tolerances controlled within ±0.05mm for optimal part accuracy

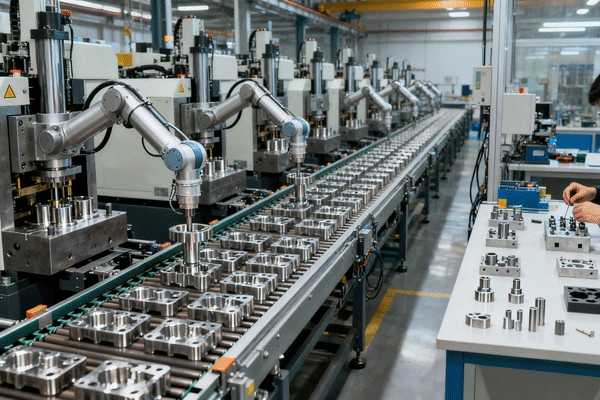

- High-volume part manufacturing by efficient production tooling

- 50+ extensive material options

- Able to rapid feedback and design validation with our advanced prototype tooling

Start a New Insert Injection Molding Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable Insert Injection Molding Services Provider from China

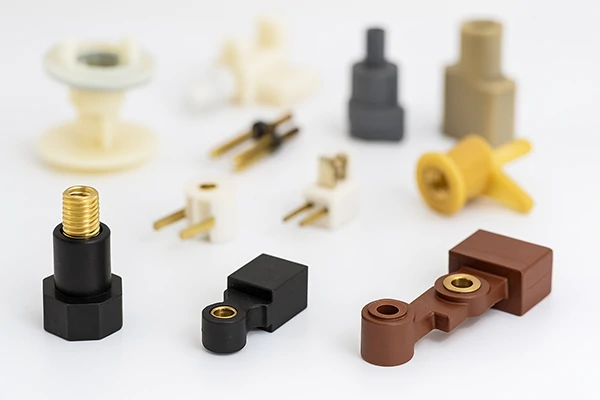

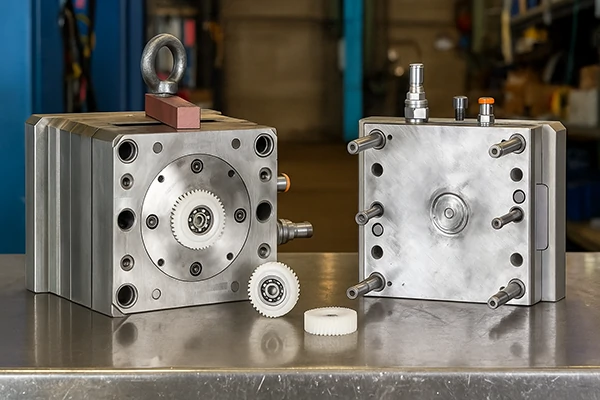

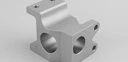

Robotika is a leading manufacturer specializing in precision insert injection molding services. With over a decade of experience, we have produced high-quality components for clients around the world. Our insert injection molding service specializes in combining metal inserts, threaded parts, or electrical components with high-quality plastic resins in a single molding cycle. This process eliminates secondary assembly, reduces labor costs, and minimizes the risk of part failure caused by loosening or misalignment. Compared to traditional assembly, insert molding delivers stronger bonding between plastic and metal, enhances product durability, and improves dimensional precision. It is the ideal solution for manufacturing parts that require electrical conductivity, high wear resistance, or reliable fastening, helping customers achieve more compact designs, better performance, and lower production costs.

We take pride in our ability to deliver reliable and efficient Insert Injection Molding solutions for industries such as automotive, electronics, medical, and consumer goods. Our extensive production capabilities, along with a commitment to quality and customer satisfaction, make us a trusted partner for businesses requiring precise, durable, and innovative molded parts.

Our Insert Injection Molding Capabilities

At Robotika, we provide insert injection molding service with precision engineering for complex parts, versatile material integration, rapid prototyping, and both high-volume and custom manufacturing. We work with a variety of materials, including metals, ceramics, and engineering plastics, ensuring that every part meets your specific requirements for strength, durability, and functionality across industries. We offer a range of surface treatment options such as powder coating and electroplating, all designed to enhance the performance and aesthetics of your parts. Our parts are produced with tight tolerances, achieving dimensional accuracy as precise as ±0.05 mm. Each component undergoes thorough quality inspections using advanced technologies like automated coordinate measuring machines (CMMs) to ensure the highest level of consistency and reliability. Whether you need complex, custom parts or high-volume production, we deliver fast, high-quality solutions tailored to your needs.

Our insert injection molding service excels in precision engineering, enabling the production of complex, high-tolerance parts with intricate designs and embedded inserts for enhanced performance and durability.

We offer versatile material integration, combining metals, ceramics, and advanced plastics to create parts that balance strength, lightweight design, and functionality for a wide range of applications.

With our rapid prototyping capabilities and streamlined production processes, we provide quick design iterations and fast turnaround times, ensuring you meet deadlines and get to market faster.

Whether you require high-volume production or custom, low-volume runs, our manufacturing capabilities are scalable to meet your needs with consistent quality, efficiency, and precision.

Insert Injection Molding Capabilities

Maximum Build Size

Our maximum molding size is up to 1000mm × 600mm × 500mm, suitable for small to medium-sized parts.

Material Compatibility

Capable of molding ABS, PP, PC, POM, Nylon, PEEK, and other engineering plastics, meeting various industrial and custom production needs.

Molding Precision

Our standard tolerance is controlled within ±0.05mm, ensuring high precision for lightweight and durable plastic components.

Surface Finishing Options

We support polishing, painting, sandblasting, electroplating, laser engraving, and more for enhanced durability and aesthetics.

Delivery Time

Our standard injection molding lead time is 7-15 days, with expedited services available for urgent projects.

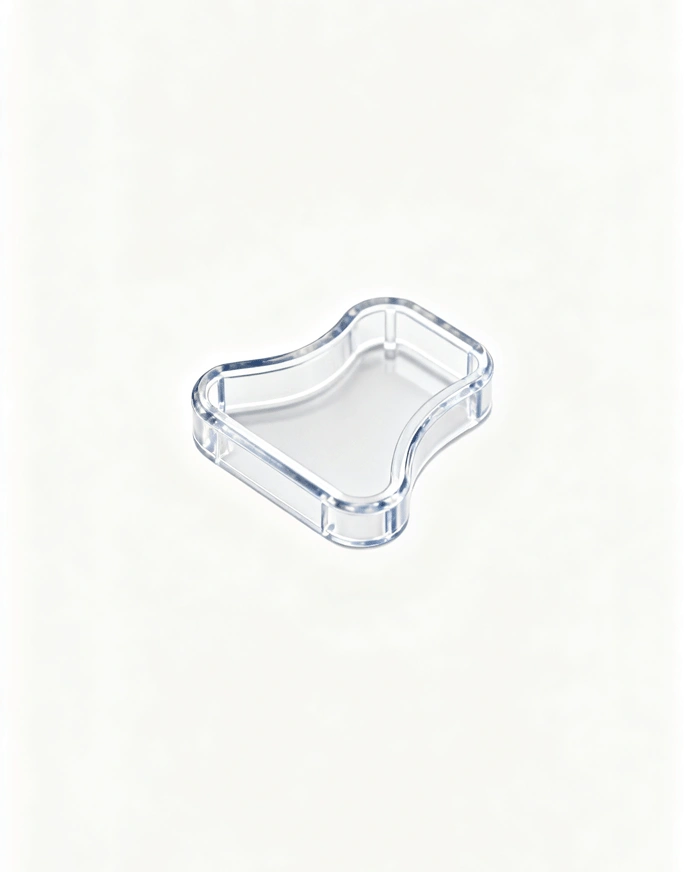

Our Latest Insert Injection Molding Products We have Manufactured

Insert Injection Molding Tolerance

| Part Type | Tolerance Range |

|---|---|

| Linear Tolerance | ±0.05 mm |

| Dimensional Tolerance | ±0.10 mm |

| Hole Diameter Tolerance | ±0.05 mm to ±0.10 mm |

| Positioning Tolerance | ±0.05 mm |

| Surface Finish | Ra 1.6 µm to Ra 3.2 µm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

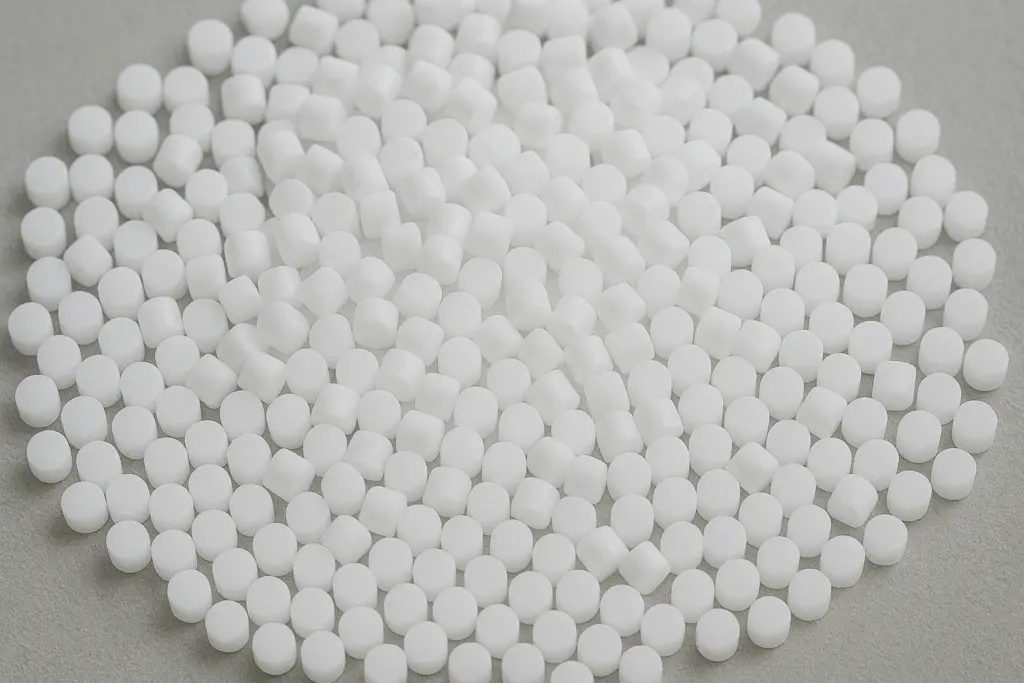

Insert Injection Molding Materials

ABS (Acrylonitrile-Butadiene-Styrene)

ABS is an excellent choice for Insert Injection Molding due to its impact resistance, high toughness, and ease of processing. It offers good strength and is suitable for manufacturing complex shapes. ABS is widely used in automotive parts, electronic housings, and consumer goods. For example, ABS inserts are commonly used in automotive dashboards and electronic device enclosures, providing durability and structural integrity.

Mill Lead Time: As fast as 3 days

Finishes: Raw, anodized, bead blasted, polished.

PP (Polypropylene)

Polypropylene is ideal for Insert Injection Molding because of its excellent chemical resistance, low density, and cost-effectiveness. It’s widely used in applications where durability and flexibility are needed. PP inserts are commonly used in automotive applications, medical devices, and consumer packaging. For example, PP inserts are often used in medical device housings and automotive clips, offering a balance of strength and lightweight properties.

Mill Lead Time: As fast as 4 days

Finishes: Raw, matte, glossy.

PE (Polyethylene)

Polyethylene is a versatile material suitable for Insert Injection Molding due to its good chemical resistance, low friction, and ease of processing. It is often used for lightweight applications that require durability. PE inserts are typically used in industrial and consumer products such as storage containers and automotive parts. For example, PE inserts are used in packaging and agricultural components, providing flexibility and impact resistance.

Mill Lead Time: As fast as 3 days

Finishes: Raw, matte, glossy.

PS (Polystyrene)

Polystyrene is ideal for Insert Injection Molding because of its rigidity, ease of processing, and versatility in producing clear, strong parts. It is widely used in consumer goods and packaging. PS inserts are commonly used in electrical housings, toys, and disposable products. For example, PS inserts are often used in the casing of household appliances and toys, offering both structural stability and aesthetic appeal.

Mill Lead Time: As fast as 4 days

Finishes: Raw, glossy, matte.

PVC (Polyvinyl Chloride)

PVC is a durable, flexible material often used in Insert Injection Molding for applications that require resistance to chemicals, UV light, and weathering. It is used in plumbing, construction, and electrical components. For instance, PVC inserts are used in plumbing fittings and electrical wiring boxes, providing chemical resistance and long-lasting durability.

Mill Lead Time: As fast as 5 days

Finishes: Raw, matte, textured.

PEEK (Polyetheretherketone)

PEEK is an ideal choice for Insert Injection Molding due to its exceptional strength, thermal stability, and resistance to chemicals. It is widely used in applications that require high-performance and high-temperature resistance. PEEK inserts are commonly used in aerospace, automotive, and medical devices. For example, PEEK inserts are used in critical automotive parts and medical implants, offering outstanding durability and heat resistance.

Mill Lead Time: As fast as 7 days

Finishes: Raw, polished, matte.

PTFE (Polytetrafluoroethylene)

PTFE is well-suited for Insert Injection Molding due to its excellent chemical resistance, low friction, and high-temperature performance. It is commonly used in applications requiring non-stick properties and resistance to harsh chemicals. PTFE inserts are often used in valve components, gaskets, and seals. For instance, PTFE inserts are used in chemical processing equipment and automotive sealing applications to ensure long-lasting performance in extreme environments.

Mill Lead Time: As fast as 6 days

Finishes: Raw, matte, polished.

PPSU (Polyphenylsulfone)

PPSU is a high-performance plastic ideal for Insert Injection Molding because of its excellent thermal stability, chemical resistance, and mechanical properties. It is commonly used in industries that require high-strength, heat-resistant parts. PPSU inserts are used in medical devices, aerospace, and automotive industries. For example, PPSU inserts are commonly found in medical instrument housings and automotive fuel systems, providing durability under high-pressure and high-temperature conditions.

Mill Lead Time: As fast as 6 days

Finishes: Raw, polished, matte.

PBT (Polybutylene Terephthalate)

PBT is well-suited for Insert Injection Molding due to its dimensional stability, high strength, and resistance to heat and chemicals. It is commonly used in automotive, electrical, and industrial applications. PBT inserts are used in automotive connectors and electrical housings to ensure reliable performance in demanding conditions. For example, PBT inserts are used in high-performance electrical connectors for automotive or industrial applications where heat resistance and durability are critical.

Mill Lead Time: As fast as 5 days

Finishes: Raw, glossy, matte.

PBT (Nylon)

Nylon offers great strength, wear resistance, and flexibility, making it ideal for Insert Injection Molding in demanding applications. It provides excellent toughness and is resistant to abrasion and chemicals. Nylon inserts are used in a wide range of applications, including automotive, industrial, and electrical components. For example, nylon inserts are commonly used in gears, bearings, and electrical housings due to their high strength-to-weight ratio and long-lasting performance.

Mill Lead Time: As fast as 4 days

Finishes: Raw, polished, matte.

Mill Lead Time: As fast as 5 days

Finishes: Raw, glossy, matte.

Finishing Options for Insert Injection Molding

| Name | Description | Can Be Applied with | Applicable Materials |

|---|---|---|---|

Anodizing

Anodizing

|

Enhances the natural oxide layer on metal parts to improve corrosion resistance and surface hardness. | Aluminum, Titanium | Aluminum alloys, Titanium |

Powder Coating

Powder Coating

|

A dry finishing process that applies a durable and protective powdered coating to the surface. | Metal inserts (e.g., aluminum, steel) | Aluminum, Steel, Brass |

Polishing

Polishing

|

Smoothens the surface to create a shiny, reflective finish that enhances aesthetics and reduces friction. | Plastics, Metals | ABS, PEEK, Aluminum, Stainless Steel |

Bead Blasting

Bead Blasting

|

Coats the surface of a part with a thin metal layer (e.g., chrome, nickel) to improve appearance and resistance. | Metal inserts | Brass, Steel, Copper |

Passivation

Passivation

|

Creates a metal coating on a surface by electro-depositing metal, adding thickness and durability. | Metal and Plastic components | Metals, Plastics |

Texturing

Texturing

|

Applies a textured pattern to improve grip, aesthetics, or functional properties like friction resistance. | Plastic, Metal | Plastics, Metals |

Laser Etching

Laser Etching

|

Uses lasers to engrave patterns, logos, or text onto the surface for fine details. | Metal, Plastic | Metals, Plastics |

Raw (Unfinished)

Raw (Unfinished)

|

Parts left in their natural, as-molded state without any surface treatment. | All materials | All materials (Plastic & Metal) |

- *We offer a range of additional finishing options, including cadmium plating, copper plating, gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Insert Injection Molding Design Guide

In this guide to insert injection molding, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

Insert Injection Molding Service FAQs

How long does it take to receive a quote?

We aim to provide a free quotation and design feedback within 24 hours of receiving your request.

Can you handle high-volume production?

Yes, we are fully equipped to handle both high-volume production and smaller, custom runs with fast turnaround times.

What is the typical lead time for production?

Lead time typically ranges from 5 to 10 business days, depending on the complexity and volume of your order.

Can I request a prototype before production?

Yes, we offer rapid prototyping to help you evaluate the design before full-scale production starts.

Do you offer custom finishing options?

Yes, we provide a variety of surface finishes such as anodizing, powder coating, polishing, and more to meet your specific requirements.

What types of parts can be produced with Insert Injection Molding?

Insert Injection Molding is ideal for parts like automotive components, medical devices, electrical connectors, and consumer electronics where strength, precision, and durability are essential.

What is the minimum order quantity?

We offer flexible production runs, with no strict minimum order quantities. Whether you need small or large batches, we can accommodate your requirements.

Insert Injection Molding Related Resource

Are You Looking for Insert Injection Molding Service Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.