Rapid Prototyping Services

Robotika provides rapid prototyping services backed by strict quality control, creating durable parts suitable for testing, validation, and short-run production.

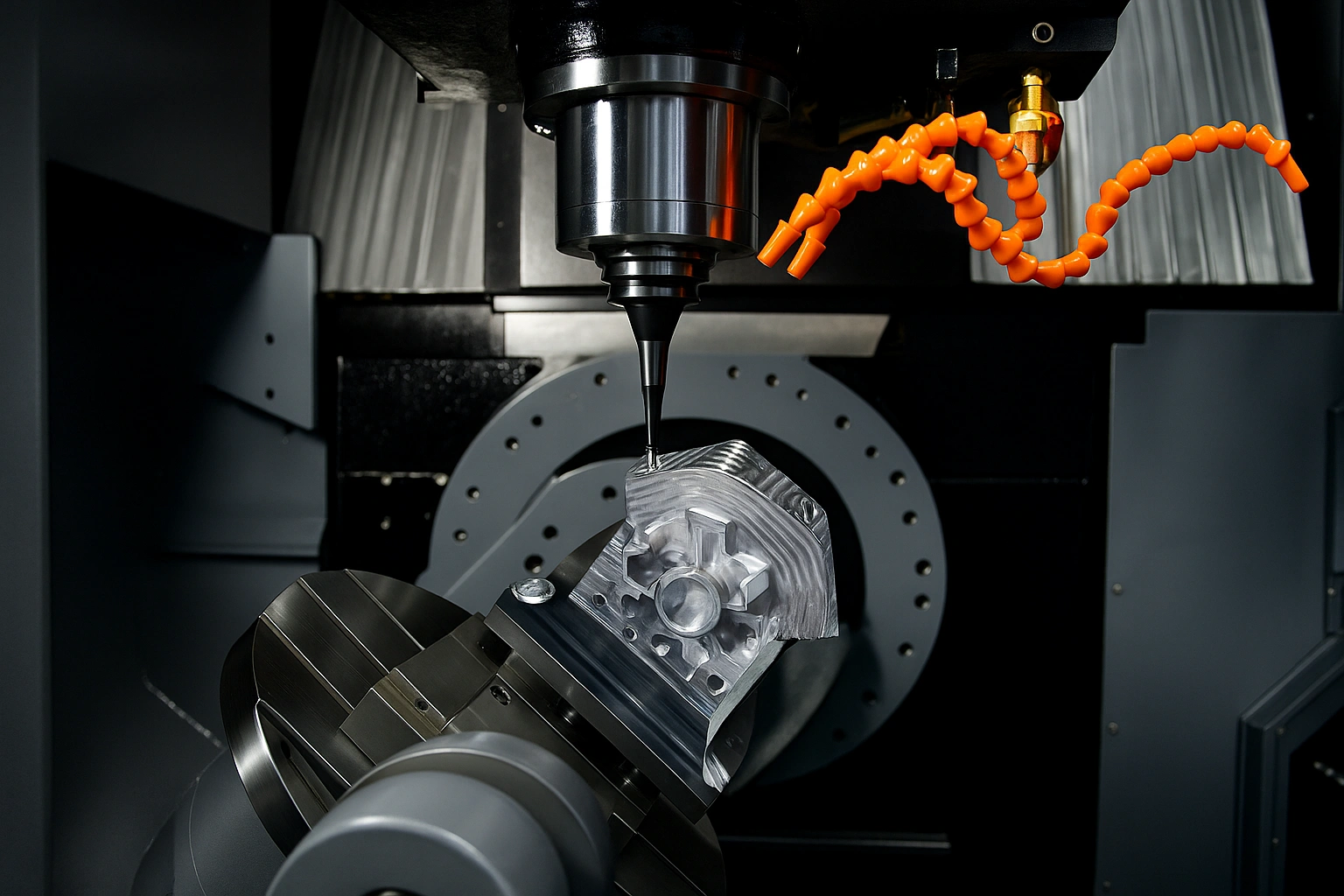

- CNC Rapid Prototyping

- Rapid Tooling

- Production Tooling

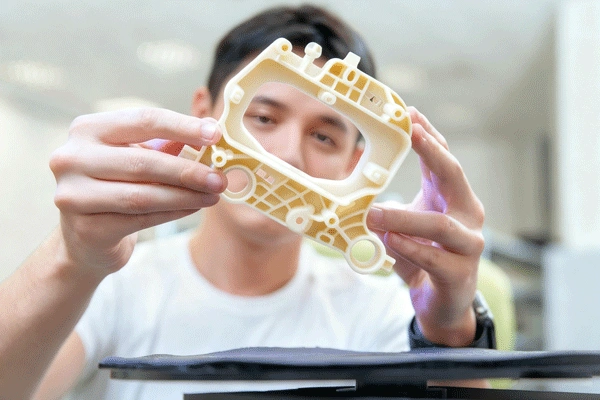

- Plastic Prototyping Services

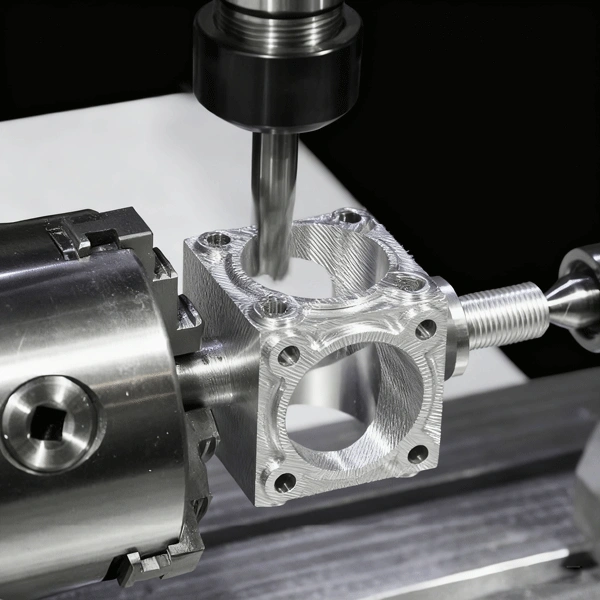

- Metal Prototyping Service

Start a New Rapid Prototyping Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable Rapid Prototyping Service Provider from China

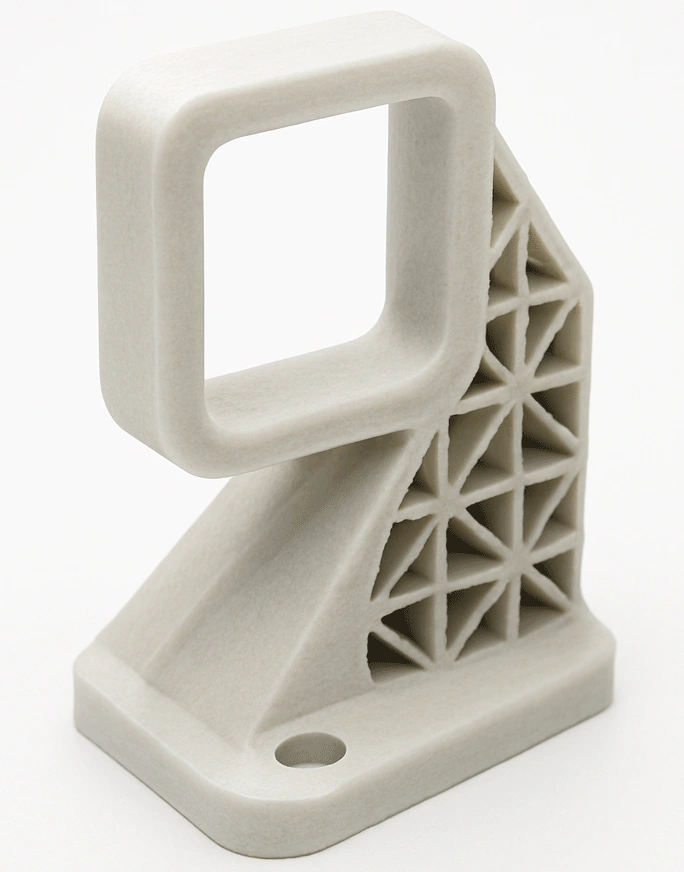

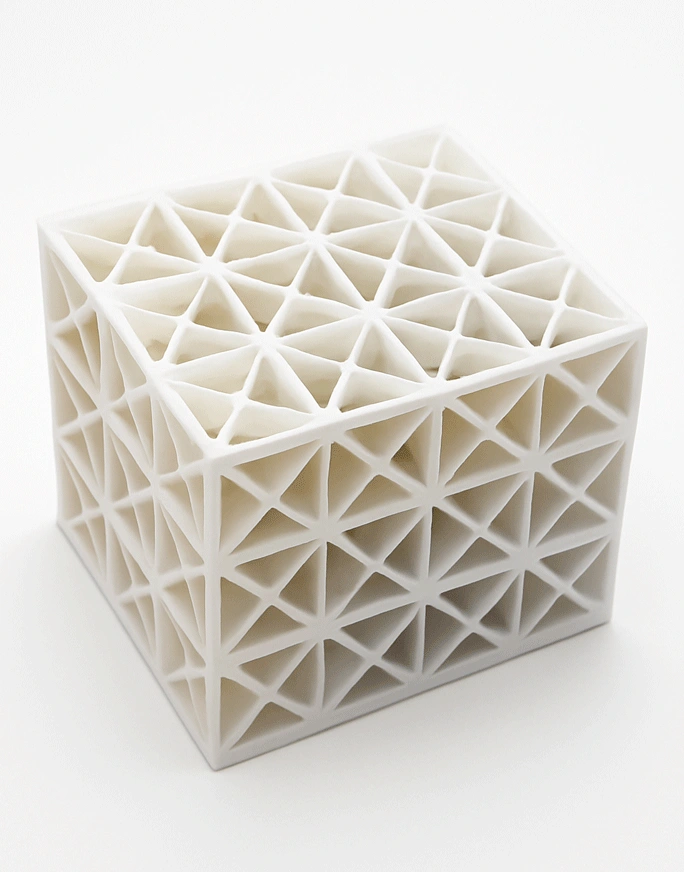

Robotika is a professional rapid prototyping manufacturer in China. Our rapid prototyping service is designed to accelerate design validation, reduce development risks, and save costs by avoiding errors before mass production. We provide DFM (Design for Manufacturability) analysis, material recommendations, and solutions for challenging geometries such as thin walls, complex cavities, and snap-fit features. Whether you require prototypes for assembly testing, surface finishing evaluation, or real-world performance trials, Robotika ensures high precision and consistent quality.

Every year, Robotika delivers thousands of prototype and bridge-production parts to industries including automotive, medical devices, aerospace, electronics, and consumer goods. Our flexible production setup enables us to support everything from one-off prototype runs to low-volume manufacturing, offering reliable lead times, tight tolerances, and professional engineering support at every stage of product development.

Our Rapid Prototyping Capabilities

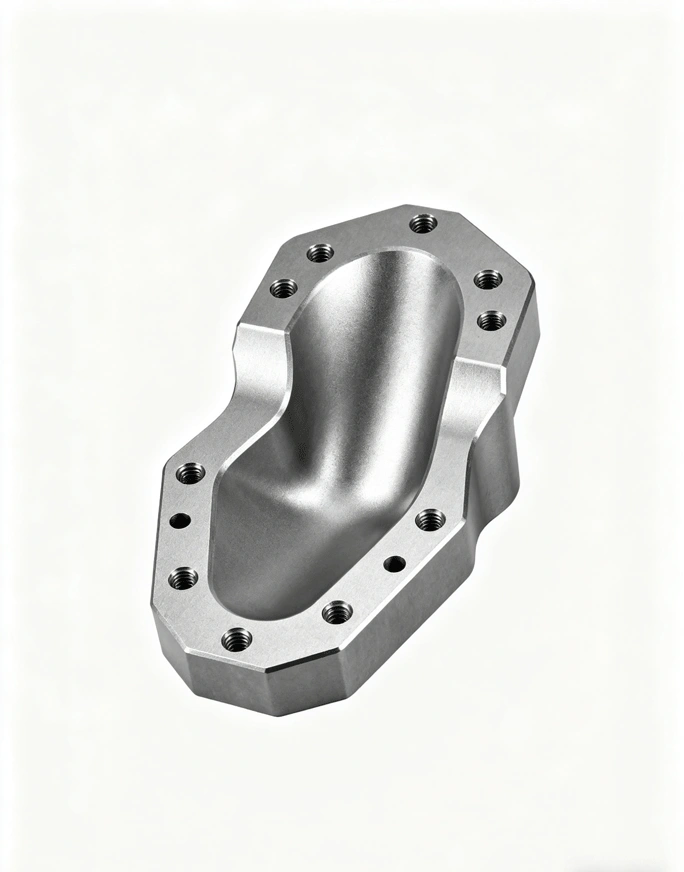

Robotika’s rapid prototyping services are built around our core strength in CNC machining, including CNC Milling, Rapid Tooling, Metal Prototyping and Plastic Prototyping. We support a wide range of materials, from commonly used plastics such as ABS, PC, PP, PA, PMMA, and PEEK, to metals including aluminum, stainless steel, brass, and titanium. We offer multiple finishing options including polishing, anodizing, bead blasting, powder coating, painting, electroplating, and silk screen printing. Depending on the process and material, our tolerances reach ±0.01 mm for CNC-machined metal parts, ±0.02–0.05 mm for CNC-machined plastic prototypes, and about ±0.05 mm for rapid injection-molded components. All prototypes are inspected with precision measurement systems such as CMMs and optical devices to ensure consistent dimensional accuracy and production-like quality.

High-precision machining for complex 2D and 3D geometries, ideal for creating functional prototypes and production-quality parts.

Advanced multi-axis capability for intricate designs, undercuts, and freeform surfaces with superior accuracy.

Fast, cost-effective tooling solutions that enable short-run plastic prototypes and bridge production.

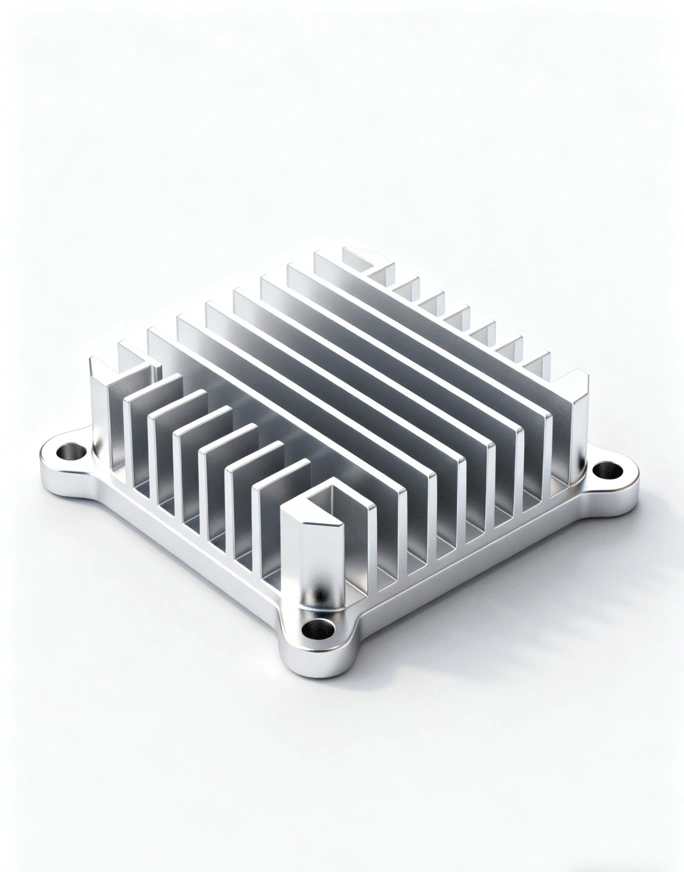

High-precision prototypes in aluminum, stainless steel, and titanium, delivering production-like strength and performance for functional testing.

Fast and cost-effective solutions for creating accurate plastic parts that validate design, fit, and function before mass production.

Rapid Prototyping Capabilities

Part size limit

950 * 550 * 480 mm (37.0 * 21.5 * 18.5 inch)

Linear dimension

+/- 0.025 mm (+/- 0.001 inch)

Hole diameters (not reamed)

+/- 0.025 mm (+/- 0.001 inch)

Shaft diameters

+/- 0.025 mm (+/- 0.001 inch)

Mold cavity tolerances

±0.05 mm

Part-to-part repeatability

±0.1 mm

Production grade

1-100,000 cycles

Features

A fast and precise solution for both plastic and metal components. Efficiently turn designs into high-quality parts, ideal for both prototyping and mass production.

Rapid Prototyping Design Guide

In this guide to Rapid Prototyping, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

Our Rapid Prototyping Capabilities

CNC Machining Prototyping

CNC machining is one of the most high-precision rapid prototyping technologies available.

Turnarounds are fast in low volumes, and CNC prototyping produces parts not too far from production quality. The cost is higher than 3D printing but the surface finish and part strength are often superior.

- CNC Milling — Milled prototype & production parts in plastic and metal

- CNC Turning — All types of round components

- CNC Grinding —Tight tolerance and good surface

- CNC EDM —For deep pocket & sharp conners.

Rapid Vacuum Casting

Rapid vacuum casting is a low-cost prototyping service for the production of low-cost plastic parts, particularly items like colorful display models.

Advantages of rapid vacuum casting include very low tooling costs compared to injection molding. And although vacuum cast parts are not especially durable, they come out of the mold with an excellent surface finish without post-processing.

The silicone mold used for rapid vacuum casting typically lasts around 20 shots, ideal for most prototyping scenarios.

- Rigid Plastics —Such as ABS, PC, PA simulate prototype parts

- Soft Rubber —Rubber like prototypes from Shore A 30 to 90 degrees.

- Wax —Patterns for low-vlume investment casting

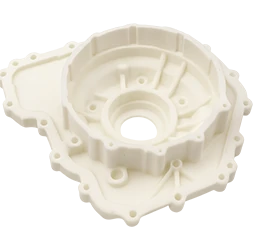

Prototyping Tooling

Prototyping tooling for molding is ideal when the customer requires between 100–2,000 units of their injection molded parts; more than this and production-level steel tooling may be preferred.

Advantages of rapid tooling include fast turnarounds and the ability to carry out prototyping and testing of injection molded parts that might otherwise take months to produce. Rapid tooling is also significantly cheaper than mass production tooling.

Although rapid tooling and rapid injection molding is more expensive than 3D printing, it provides plastic parts much nearer to production quality that can therefore be used for functional testing.

- Plastic Injection Mold

- Metal Prototyping Service

Sheet Metal Molding

Sheet metal molding is ideal for producing precise and durable metal parts in medium to high volumes. It is widely used for enclosures, brackets, and mechanical assemblies requiring strength and accuracy.

It offers short production cycles, high repeatability, and cost efficiency compared with machining, supporting materials like aluminum, stainless steel, and copper.

Though tooling costs are higher than simple fabrication, sheet metal molding ensures tight tolerances, consistent quality, and excellent surface finishes for both prototypes and production parts.

- Plastic Injection Mold

- Sheet Metal Prototyping

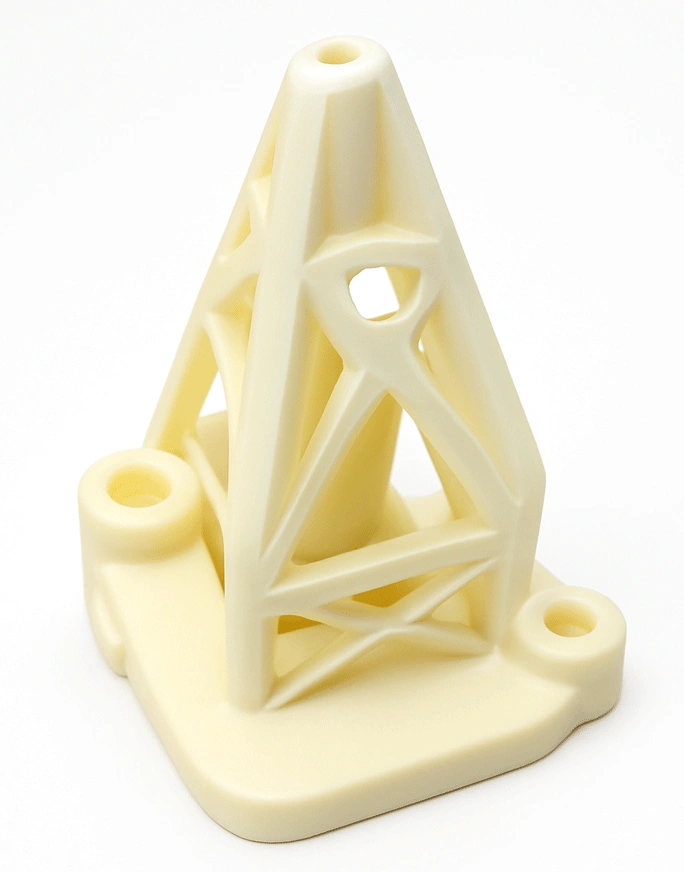

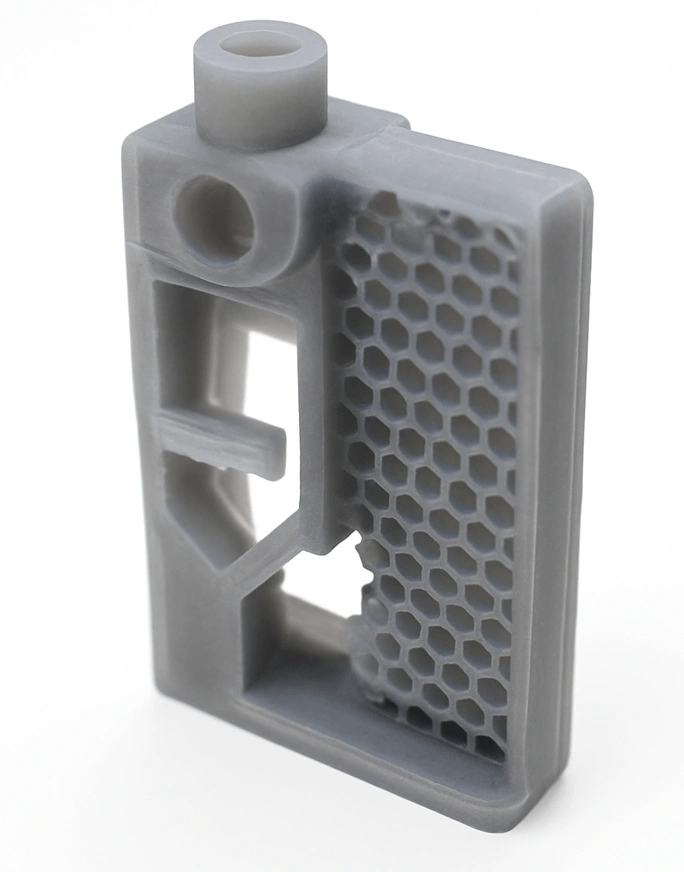

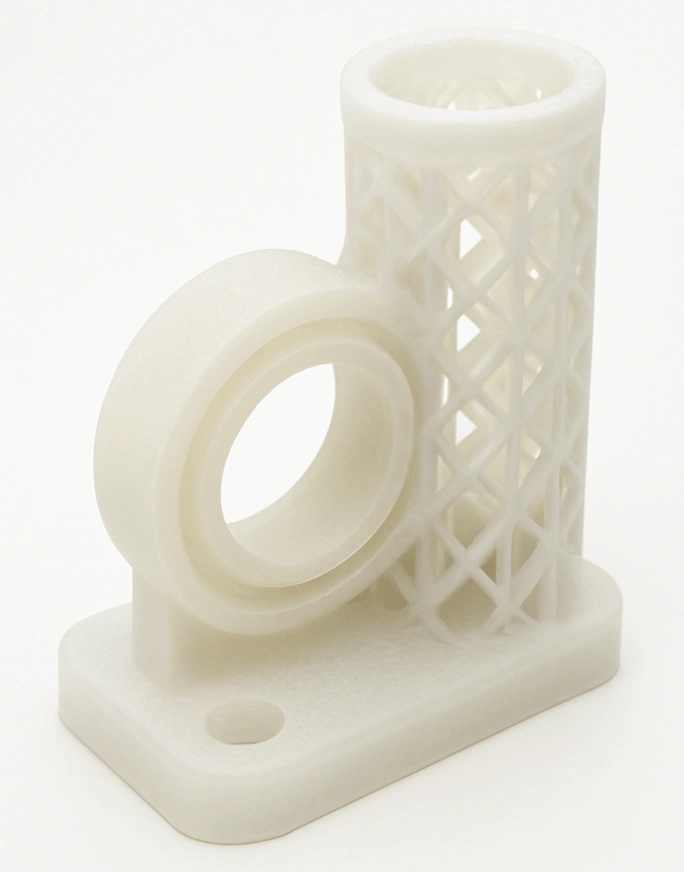

Our Latest Rapid Prototyping Products We have Manufactured

Our rapid prototyping services enable clients to transform ideas into tangible products with speed and precision. By combining advanced CNC machining, 3D printing, and injection molding technologies, we create prototypes that accurately replicate the final product’s design, function, and appearance. These prototypes are not only essential for product validation and functional testing but also help shorten development cycles and reduce costs. Whether you need a single concept model or multiple parts for engineering evaluation, our expertise ensures high-quality results that meet diverse industry needs—from consumer products and electronics to automotive and medical devices.

Rapid Prototyping Services FAQs

How long does it take to get a prototype?

We typically deliver prototypes within 3-10 business days, depending on the complexity and materials used. We always work to meet your deadlines and ensure fast turnaround.

What materials can you use for rapid prototyping?

We offer a wide range of materials for both plastic and metal prototypes, including engineering plastics, aluminum, stainless steel, titanium, and more. If you have a specific material in mind, just let us know!

Can I get a quote before placing an order?

Yes, absolutely! Simply provide us with your design files and requirements, and we will send you a detailed quote for your prototype.

Do you accept custom design requests?

Yes! Our team can work with you on custom designs to meet your exact specifications. Feel free to share your ideas, and we’ll help bring them to life.

What is your minimum order quantity (MOQ)?

For prototyping services, we have no minimum order requirement. Whether you need a single prototype or a small batch, we’re here to help.

Can you handle both small and large production runs?

Yes! We specialize in both low-volume production runs and large-scale manufacturing, ensuring flexibility to meet your needs as your project scales.

How do you ensure the quality of my prototype?

We use advanced quality control methods, including 3D scanning and precision measurement tools like CMMs, to ensure your prototype meets exact specifications.

Will I receive an updated prototype if there are design changes?

Yes, we can quickly update and revise your prototypes to accommodate design changes, ensuring you get exactly what you need before final production.

What happens if my prototype doesn’t meet expectations?

We’re committed to your satisfaction. If there are any issues with your prototype, we’ll work with you to revise and improve it until it meets your expectations.

How do I place an order?

Simply send us your design files and project details. Our team will guide you through the process and provide all the necessary information for a smooth order experience.

Are You Looking for Rapid Prototyping Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.