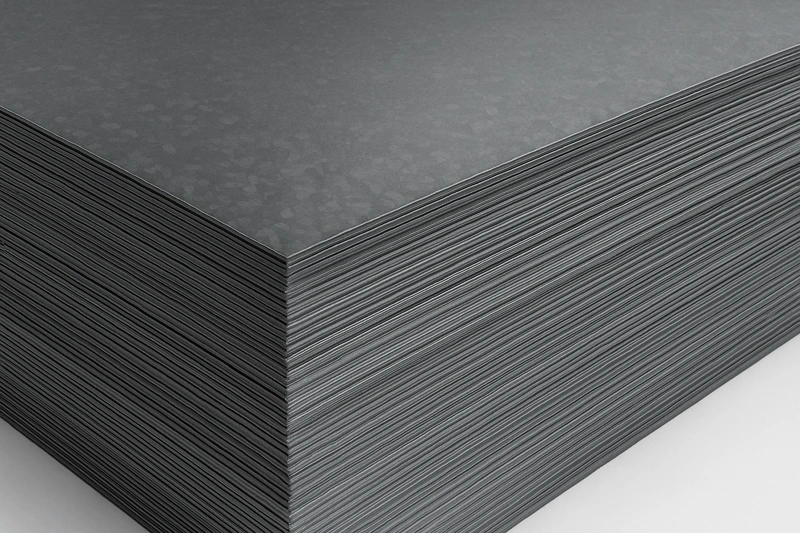

Alloy steels are tailored for enhanced strength, wear resistance, and heat resistance, making them ideal for heavy-duty applications. Alloy steel is widely used in industrial equipment, automotive, and manufacturing. For example, alloy steel is used for gears and industrial machinery parts due to its strength and durability.

- Mill Lead Time: 10–15 days

- Finishes: Polished, coated