CNC Manufacturing for Aerospace

Robotika provides precision CNC machining services tailored to the aerospace sector’s high standards. The fastest mold guarantee in 7 days.

- Stringent quality control meeting AS9100 and ISO 9001:2015 standards

- Cost-effective solutions for both low-volume prototypes and large-scale production

- Aerospace-grade materials including titanium, aluminum 7075, superalloys and high-performance thermoplastics like PEEK, Ultem, and PPS

- DFM Analysis from Industry Experts

Start Manufacturing Your Aerospace Parts!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable CNC Aerospace Parts Supplier from China

Robotika specializes in CNC machining services for aerospace applications. Equipped with advanced 3-, 4-, and 5-axis machining centers, high-speed EDM, and tight-tolerance equipment, we excel at quick-turn prototyping and low- to medium-volume production of complex aerospace parts. Our efficient workflow enables us to deliver functional prototypes in as little as 1-3 days.

We provide comprehensive support from design to production, including Design for Manufacturability (DFM) analysis, guidance on aerospace-grade metal and polymer material selection, and rigorous quality control. With over 10 years of experience and delivering over 100,000 parts annually, Robotika serves numerous aerospace companies, defense contractors, drone startups, and advanced engineering firms worldwide.

What kind of aerospace & defense parts can we make?

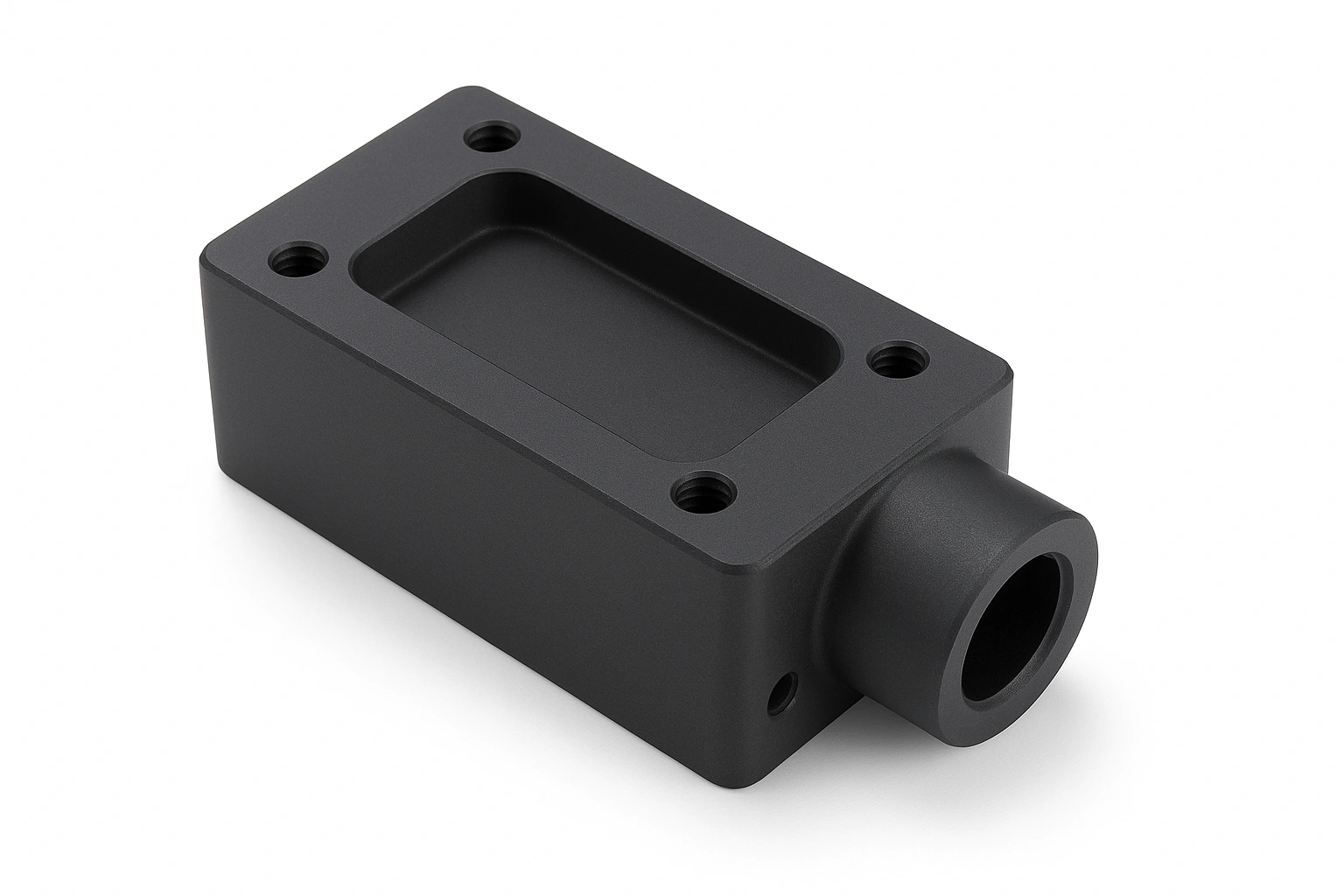

Robotika manufactures a variety of high-precision aerospace and defense components through CNC machining. We produce complex parts such as housings, brackets, structural supports, enclosures, and insulators used in critical systems like UAVs, aircraft, and satellites. Our material capabilities include aerospace-grade aluminum alloys, stainless steel, titanium, copper, and advanced engineering plastics such as PEEK, PPSU, and glass-filled nylon, selected for their performance, flame retardancy, and lightweight characteristics. To meet the stringent requirements of the aerospace and defense industry, we offer a wide range of surface finish options, and all parts are thoroughly dimensionally verified using automated coordinate measuring machines and visual inspection to achieve tight tolerances (as low as ±0.01 mm).

- Aircraft Interior Paneling

- Ventilation Ducts

- Cable Management Channels

- Aerodynamic Fairings

- Radomes

- Access Panels

- Seat Components

- Avionics Housings

- Door Locking Systems

- Wire Harness Clips

- Thermal Insulation Panels

- Window Shades

- Overhead Bin Components

- Armrests

- Cockpit Control Knobs

- Switch Housings

- Lighting Fixtures

- Oxygen Mask Components

- Fastening Clips and Brackets

- EMI/RFI Shielded Enclosures

- Engine Component Covers

- Fuel System Housings

- Door Latches and Handles

- Airflow Control Valves

Aerospace CNC Machining Capabilities

Supported Materials

We specialize in machining aerospace-grade materials such as aluminum alloys (6061, 7075), titanium (Ti-6Al-4V), stainless steel (304, 316L), and advanced plastics like PEEK and PTFE, suitable for demanding aerospace applications.

Machining Accuracy

We maintain standard tolerance within ±0.01mm, ensuring high precision for aerospace components, including structural parts and engine components.

Maximum Machining Size

Our maximum machining size is 1000mm × 600mm × 500mm, accommodating a wide range of aerospace parts.

Surface Finishing Options

We offer anodizing, polishing, bead blasting, powder coating, and other finishes to enhance part durability and performance.

Delivery Time

Standard CNC machining lead time is 5-10 days, with expedited services for urgent aerospace projects.

Experience the boundless possibilities of customization

Enhance your aerospace components with advanced surface finishes and precision tolerance. At Robotika, we tailor each part to meet your exact specifications, including finishing and material selection, ensuring performance, reliability, and full compliance with aerospace standards.

| Name | Tolerance Range |

|---|---|

| Standard Aerospace Parts | ±0.2 mm to ±0.5 mm |

| Precision Aerospace Parts | ±0.05 mm to ±0.2 mm |

| Complex Aerospace Parts | ±0.2 mm to ±0.5 mm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

| Name | Description | Can Be Applied with | |

|---|---|---|---|

|

Anodizing (Type I, II, III) | Improves corrosion resistance and surface hardness, commonly used for aluminum alloys. | Aircraft frames, wing structures, engine parts, landing gear components |

|

Passivation | Enhances corrosion resistance by removing free iron and creating a protective oxide layer. | Aircraft engine parts, structural components, fasteners |

|

Electropolishing | Polishes metal parts to improve smoothness, reduce friction, and enhance corrosion resistance. | Stainless steel parts in aircraft interiors, turbine blades |

|

Powder Coating | Provides a durable coating that offers protection against wear, chemicals, and environmental factors. | Aircraft exterior parts, engine components, cockpit panels |

|

Nickel Plating | Adds a layer of nickel to improve surface hardness, corrosion resistance, and wear resistance. | Aerospace engine components, valve seats, brackets |

|

Bead Blasting | Removes contaminants and imparts a smooth, matte finish, improving aesthetics. | Aircraft fuselage, wing components, turbine parts |

|

Polishing | Creates a smooth and shiny surface, enhancing appearance and reducing friction. | Aircraft exterior components, turbine blades, structural parts |

|

Chemical Conversion Coating (Alodine/Chemfilm) | Provides a corrosion-resistant coating for aluminum parts exposed to harsh environments. | Aircraft fuselage, wings, engine components |

|

Hard Coat Anodizing | A more durable anodizing option, offering increased hardness and wear resistance for high wear conditions. | Aircraft structural components, engine parts, landing gear |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Aluminum alloys (6061, 7075)

Aluminum alloys (6061, 7075) are ideal for aerospace CNC machining due to their excellent strength-to-weight ratio, corrosion resistance, and ease of machinability. 6061 offers good formability and weldability, while 7075 provides higher strength, making both alloys suitable for demanding aerospace applications. These materials are commonly used for aircraft frames, wing structures, and engine components, such as brackets, fuselage parts, and landing gear. Their versatility ensures that high-performance, lightweight components meet strict aerospace standards.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, anodized, bead blasted, polished

Titanium alloys (Ti-6Al-4V)

Titanium alloys (Ti-6Al-4V) are perfect for aerospace CNC machining due to their exceptional strength-to-weight ratio, high corrosion resistance, and ability to withstand extreme temperatures. Ti-6Al-4V is particularly valued for its durability and lightweight nature, making it ideal for aerospace applications where performance and reliability are crucial. This alloy is widely used for turbine blades, engine components, and structural parts in aircraft and spacecraft, ensuring strength without adding excessive weight.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, anodized, bead blasted, polished

Stainless steel (304, 316L)

Stainless steel (304, 316L) is well-suited for aerospace CNC machining due to its high strength, excellent corrosion resistance, and ability to perform in extreme environments. Both 304 and 316L stainless steels are durable and resistant to high temperatures, making them ideal for aerospace applications. They are commonly used for structural components, fasteners, brackets, and engine parts, ensuring reliability and safety in aircraft and spacecraft operations.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, anodized, bead blasted, polished

Nickel alloys (Inconel 718)

Nickel alloys (Inconel 718) are ideal for aerospace CNC machining due to their exceptional high-temperature strength, oxidation resistance, and ability to withstand harsh environments. Inconel 718 maintains its properties even under extreme heat, making it perfect for critical aerospace applications. It is commonly used for turbine blades, engine components, and exhaust systems, ensuring durability and performance in aerospace engines and high-stress environments.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, anodized, bead blasted, polished

PEEK

PEEK is highly suitable for aerospace CNC machining due to its exceptional strength, thermal stability, and chemical resistance. It can withstand high temperatures, making it ideal for demanding aerospace applications. PEEK is often used in aerospace for manufacturing lightweight, durable components such as seals, insulation parts, and structural components in aircraft engines and systems, ensuring high performance and reliability.

- Mill Lead Time: Up to 3 days

- Color: Black, neutral matte finish

PTFE

PTFE is ideal for aerospace CNC machining due to its exceptional chemical resistance, low friction, and high-temperature stability. PTFE’s non-stick properties make it suitable for components that need to endure harsh environments and reduce wear. It is commonly used in aerospace for manufacturing seals, gaskets, bearings, and insulation parts, ensuring long-lasting performance in engines and fuel systems.

- Mill Lead Time: Up to 3 days

- Color: White, matte finish

Ultem

Ultem is ideal for aerospace CNC machining due to its high strength, thermal stability, and excellent flame resistance. It can withstand extreme temperatures and harsh chemicals, making it perfect for demanding aerospace applications. Ultem is commonly used for manufacturing structural components, electrical connectors, and insulation parts in aircraft and spacecraft, providing durability and reliability in high-performance systems.

- Mill Lead Time: Up to 3 days

- Color: Amber, transparent finish

ABS

ABS is ideal for aerospace CNC machining due to its excellent mechanical properties, impact resistance, and ease of processing. It offers good strength while being lightweight, making it suitable for less critical, non-structural aerospace components. ABS is commonly used for producing interior parts, instrument housings, and covers for aircraft, ensuring high durability and precision.

- Mill Lead Time: Up to 3 days

- Color: Black, neutral matte finish

Nylon

Nylon is an excellent choice for aerospace CNC machining due to its high strength, durability, and wear resistance. It also offers good chemical resistance and can withstand moderate temperatures, making it suitable for aerospace applications. Nylon is commonly used for manufacturing bushings, bearings, gears, and other lightweight, high-strength components that require low friction and wear resistance in aircraft and spacecraft systems.

- Mill Lead Time: Up to 3 days

- Color: Natural, black finish

Carbon fiber composites

Carbon fiber composites are ideal for aerospace CNC machining due to their lightweight, high strength, and exceptional stiffness. Materials like T700, T800, and IM7 offer excellent resistance to corrosion and fatigue, making them perfect for high-performance aerospace parts. These composites are commonly used in aerospace for components such as wings, fuselage structures, and engine parts, where minimizing weight while maintaining strength is crucial for fuel efficiency and performance.

- Mill Lead Time: Up to 3 days

- Color: Black, matte finish

Glass fiber composites

Glass fiber composites are ideal for aerospace CNC machining due to their high strength, lightweight properties, and resistance to corrosion and wear. Materials like G10, S2 Glass, and E-glass offer excellent durability and are easy to machine, making them suitable for demanding aerospace applications. Glass fiber composites are commonly used in aerospace for manufacturing structural components, interior panels, and insulation parts, providing enhanced strength while reducing weight in aircraft and spacecraft.

- Mill Lead Time: Up to 3 days

- Color: Black, neutral matte finish

Aerospace CNC Machining FAQs

Lead time depends on complexity and quantity, but prototypes can be ready in as fast as 3–5 days. Production runs usually take 7–15 days.

Yes, we regularly machine aerospace-grade metals including 7075-T6, 6061, 17-4PH stainless steel, and titanium alloys.

Yes, just send us your STEP or IGES file—we can also work with drawings if tolerances or finishes need to be specified.

Absolutely. Upon request, we can provide CoC, RoHS reports, and full material traceability documentation.

We follow strict inspection processes, including CMM measurement, first article inspection, and dimensional reports with every batch.

Just send your 3D file, any 2D drawings if available, and let us know the quantity, material, finish, and delivery timeline.

Start Your Aerospace CNC Machining Project Now!

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.