Short-Run & Mass Production Mold Making Services

Robotika provides custom mold-making services for both short-run and mass production with a fast lead time.

- Tolerances controlled as tight as ±0.01mm

- Advanced DFM analysis and mold flow simulation ensure optimized designs

- Flexible solutions for both validation and high-volume manufacturing

- High-accuracy CNC milling, turning, and EDM

Start a New Mold Making Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable Injection Mold Making Services Provider from China

Robotika is a professional mold making manufacturer in China. With over a decade of experience, Robotika has supplied hundreds of precision molds to clients worldwide. Our team ensures every mold is designed for high efficiency, long lifespan, and minimal maintenance, helping reduce production downtime and overall costs.By applying advanced DFM analysis and mold flow simulation, we identify potential issues such as part warpage, sink marks, or uneven filling before tooling begins, saving clients from costly rework. Our precision machining capability guarantees molds that produce consistent, high-quality parts, enabling faster product launches, smoother mass production, and greater market competitiveness.

By combining advanced mold-making technology with strict quality inspection, we guarantee stable performance, fast lead times, and cost-effective manufacturing support for your projects.

Our Mold Making Capacities

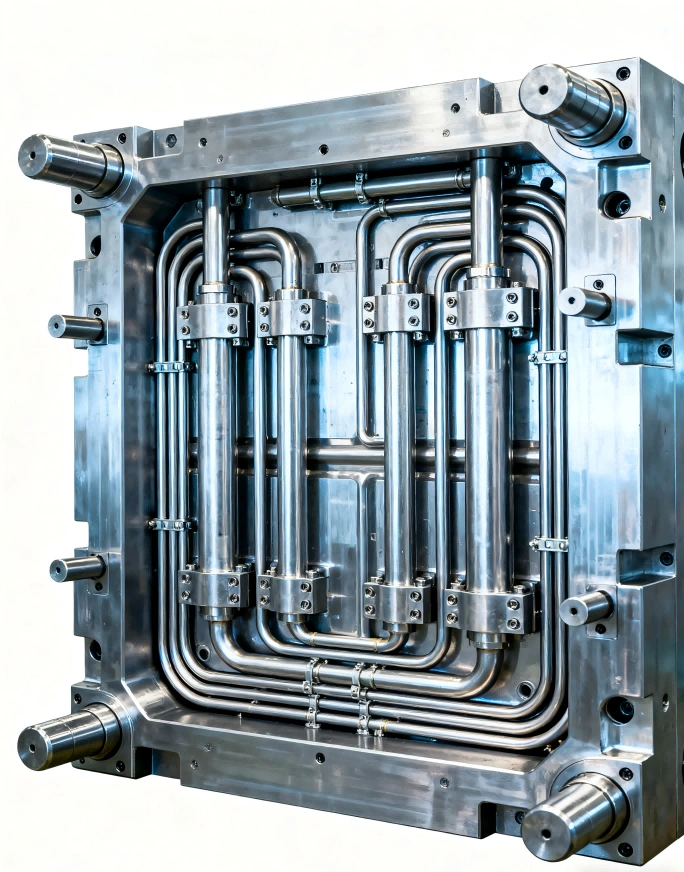

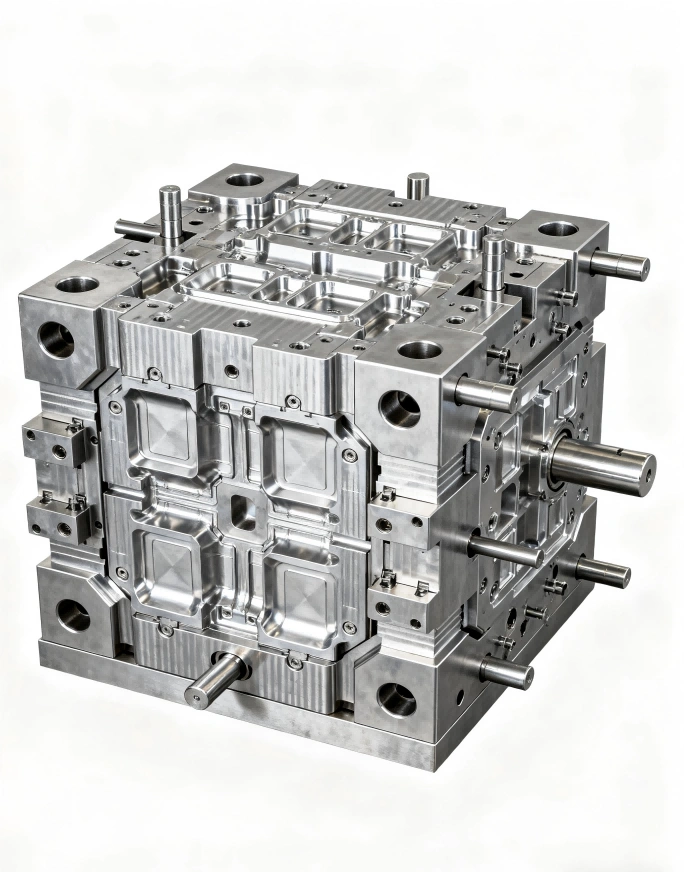

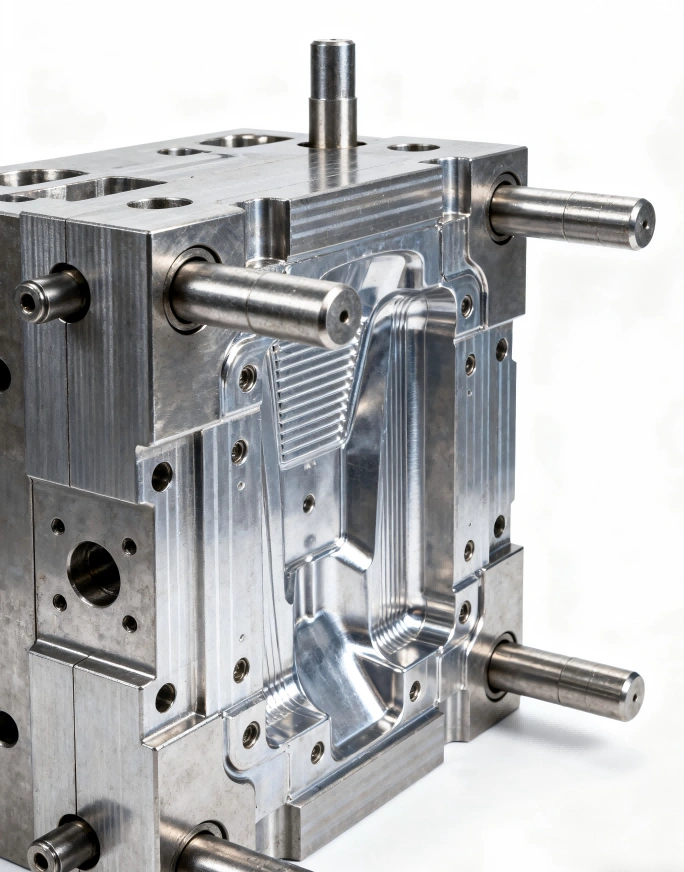

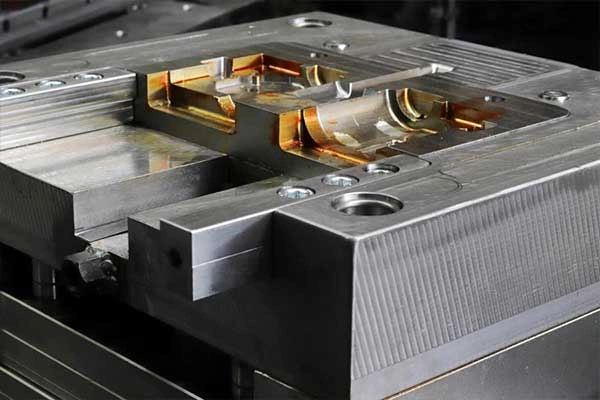

Robotika provides a full range of injection mold making services, including custom mold design & engineering, precision CNC and EDM machining, prototype & production tooling, and multi-cavity & complex mold solutions. Our team works with a wide selection of materials such as hardened tool steel (P20, H13, S136), stainless steel, aluminum, and engineering plastics for mold inserts and components. We offer multiple surface treatment options such as polishing, texturing, nitriding, hard chrome plating, and coating. With advanced CNC machining and EDM processing, our mold making operations can achieve tolerances as tight as ±0.01 mm, supported by strict quality inspections with CMM and other precision measuring equipment. This ensures every mold we deliver meets the highest standards of dimensional accuracy, reliability, and production efficiency.

Advanced DFM analysis and mold flow simulation ensure optimized designs that reduce risks, improve part quality, and extend mold life.

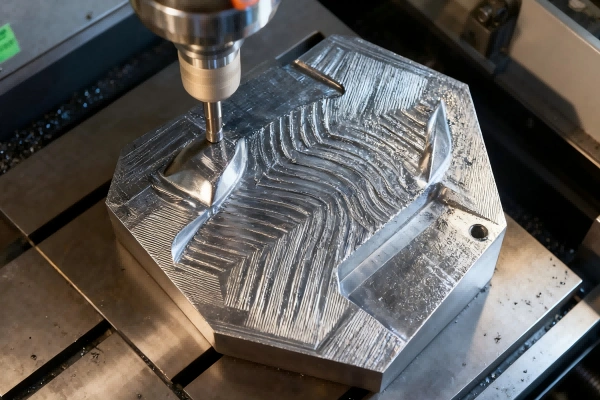

High-accuracy CNC milling, turning, and EDM deliver complex geometries and tight tolerances for durable, reliable molds.

From rapid prototype molds to hardened steel production tooling, we provide flexible solutions for both validation and high-volume manufacturing.

Expertise in multi-cavity, hot runner, 2K, and overmolding molds to boost efficiency, reduce cycle times, and meet diverse production needs.

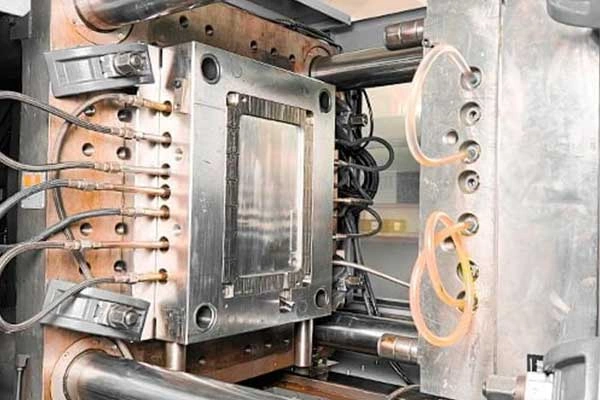

Efficient for high-volume production of precise plastic parts.

Injection Mold Making Capabilities

Full DFM reports

We offer full DFM (Design for Manufacturability) analysis, mold flow simulation, and material selection guidance, helping optimize designs and reduce potential risks.

Wide range of molds

We offer several different types of molds, which means you can avoid splitting your projects; just send everything to us to ensure your project runs smoothly.

Molding Precision

We can achieve tolerances as tight as ±0.01 mm, ensuring high precision for lightweight and durable plastic components.

Surface Finishing Options

We offer multiple surface treatment options such as polishing, texturing, nitriding, hard chrome plating, and coating to enhance the performance and lifespan of molds.

Delivery Time

Our standard lead time is 7-15 days, with expedited services available for urgent projects.

Study Case of Our Injection Mold Making Service

Types of Molds We are Offering

Plastic injection molds are aluminum or steel molds used to make parts from a wide range of plastics, including nylons, acrylics, elastomers and reinforced materials like glass-filled polyamide. Custom plastic molds can last between 100,000 and 1,000,000 shots.

Metal injection molding (MIM) is a form of injection molding where a metal and binder mix is used as feedstock. A metal injection mold is usually made from tool steel to withstand the metal injection, but we can also use aluminum.

Prototype molds are used for short-run production and design validation before full-scale manufacturing. We use precision CNC machining and EDM processes to produce prototype molds quickly and cost-effectively, ensuring fast turnaround and dimensional accuracy.

Our experience making sheet metal molds for stamping and bending allows us to create sheet metal prototypes.

How it Works

DFM

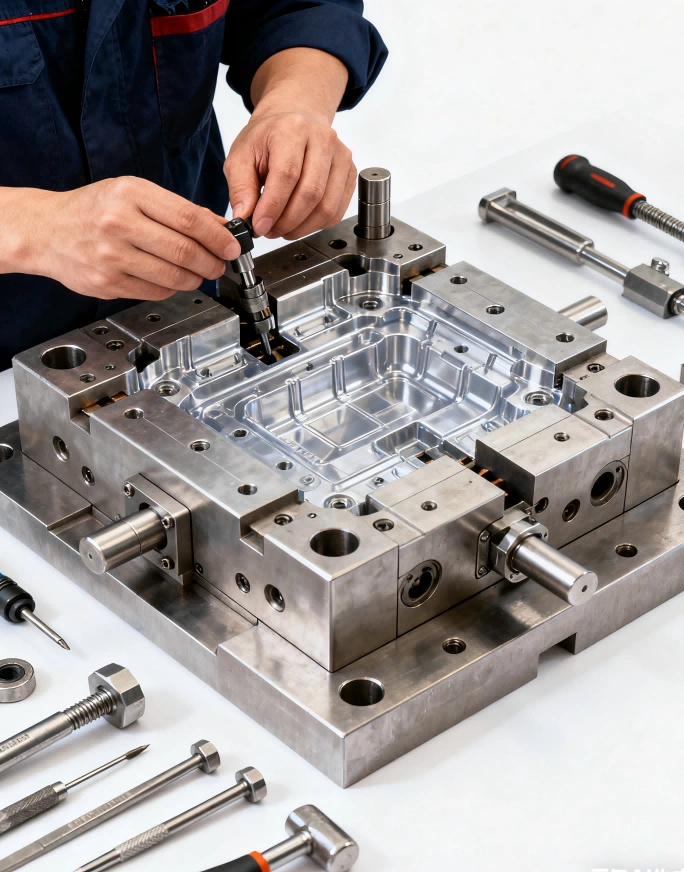

As soon as the customer confirms the order of molds, we will start to do an initial analysis of the parts to get an idea of the part line, gate positions, cooling system layout, and other key mold design considerations.

Mold design and mold flow analysis

The second step involves the use of predictive modeling software which allows us to see how the molten material will behave when it enters the mold, allowing for further improvements to the design.

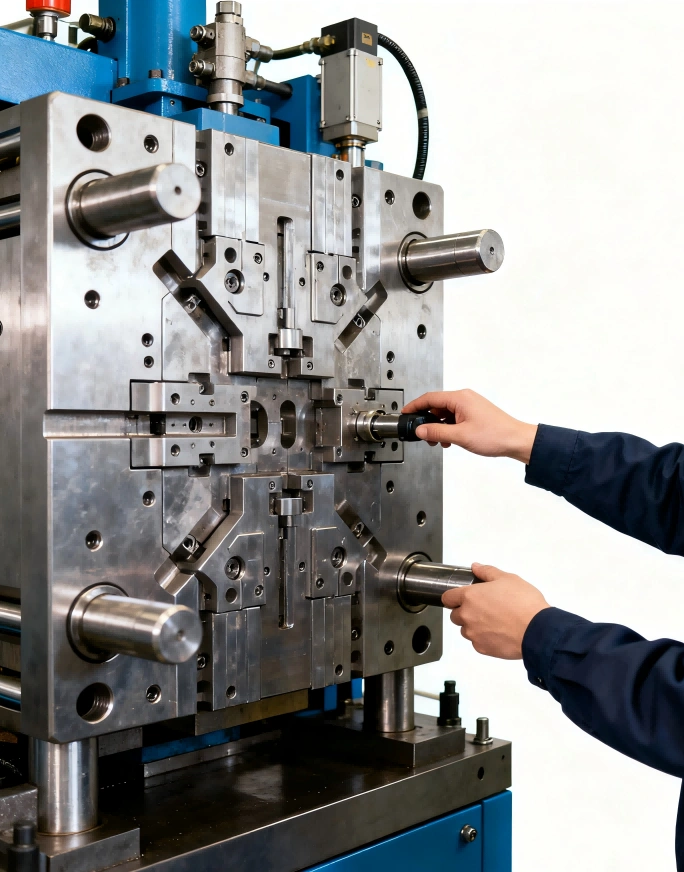

CNC machining and EDM

We make the first molds using high-quality machining equipment, with the plastic, steel, aluminum, etc. chosen by the customer to ensure precision, durability, efficiency, and reliability.

T1 sample

With the newly made molds, we make a T1 sample to have a clear vision of how the customer’s final molded parts will turn out.

Improvement if necessary

Based on our analysis of the T1 sample, we review the mold design and make any adjustments needed.

Commence Production and Shipping

We manufacture the molds in accordance with the final specifications before shipping them to the customer.

Injection Mold Making Service FAQs

What information do you need to provide a mold quote?

We usually need 3D/2D drawings, material requirements, estimated quantities, and surface finish preferences. The more details you share, the faster we can quote.

What is your typical lead time for mold making?

Prototype molds can be finished in about 2–4 weeks, while production molds usually take 4–6 weeks depending on complexity.

Can you make a prototype mold before mass production?

Yes, we offer prototype tooling to test part design, material behavior, and performance before building a production mold.

What is the minimum order quantity (MOQ) for mold making?

There is no strict MOQ for mold manufacturing. We can support both low-volume prototype runs and high-volume production.

Do you provide DFM or mold design suggestions before production?

Absolutely. Our engineers provide DFM analysis and mold flow feedback to help optimize your design and avoid costly changes later.

How do you ensure mold quality before delivery?

Every mold goes through trial runs (T1/T2 samples), dimensional inspection, and durability testing to ensure it meets your requirements.

Can you ship molds overseas and provide after-sales support?

Yes, we ship molds worldwide with secure packing. We also provide online support, spare parts, and maintenance guidance when needed.

Mold Making Related Resource

Are You Looking for Mold Making Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.