Low-Volume Manufacturing Services

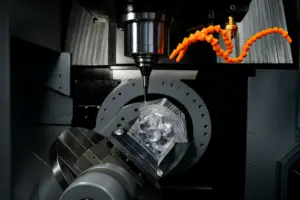

Robotika offers low-volume manufacturing services for precision CNC machined parts. With fast turnaround times, we deliver high-quality components tailored to your specifications.

- standard lead time 7days

- Tolerances controlled within ±0.05mm

- Extensive material options and kinds of finishing options

- Commitment to high precision and rapid turnaround

Start a New CNC Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable Low-Volume Manufacturing Services Provider from China

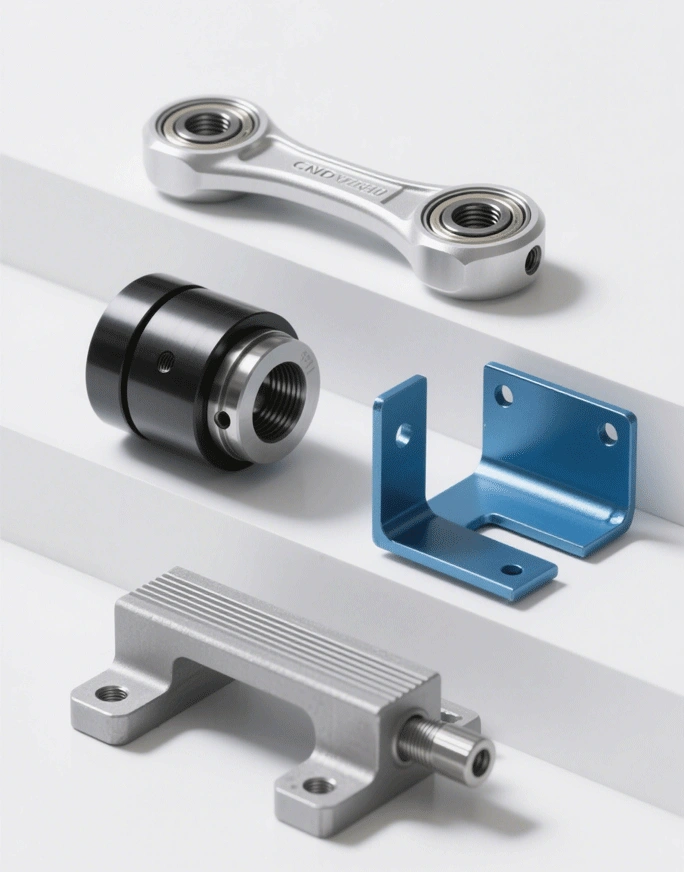

Robotika is a leading CNC machining manufacturer specializing in low-volume manufacturing services for custom metal and plastic parts. Our low-volume production ranges from 50 to 5,000 units, ensuring tight tolerances and superior quality for each part. By helping you reduce tooling costs and shorten development timelines, we enable faster iterations and efficient product validation. Our team provides comprehensive technical support, including material selection, design for manufacturability (DFM) analysis, surface finishing, and additional machining to ensure that your parts meet both functional and aesthetic requirements without the overhead of large-scale manufacturing.

With extensive experience serving industries like aerospace, automotive, medical, and consumer electronics, Robotika supports clients through every stage of product development, delivering flexible capacity, fast lead times, and consistent, high-quality production to meet your unique needs.

Our Low-Volume Manufacturing Capabilities

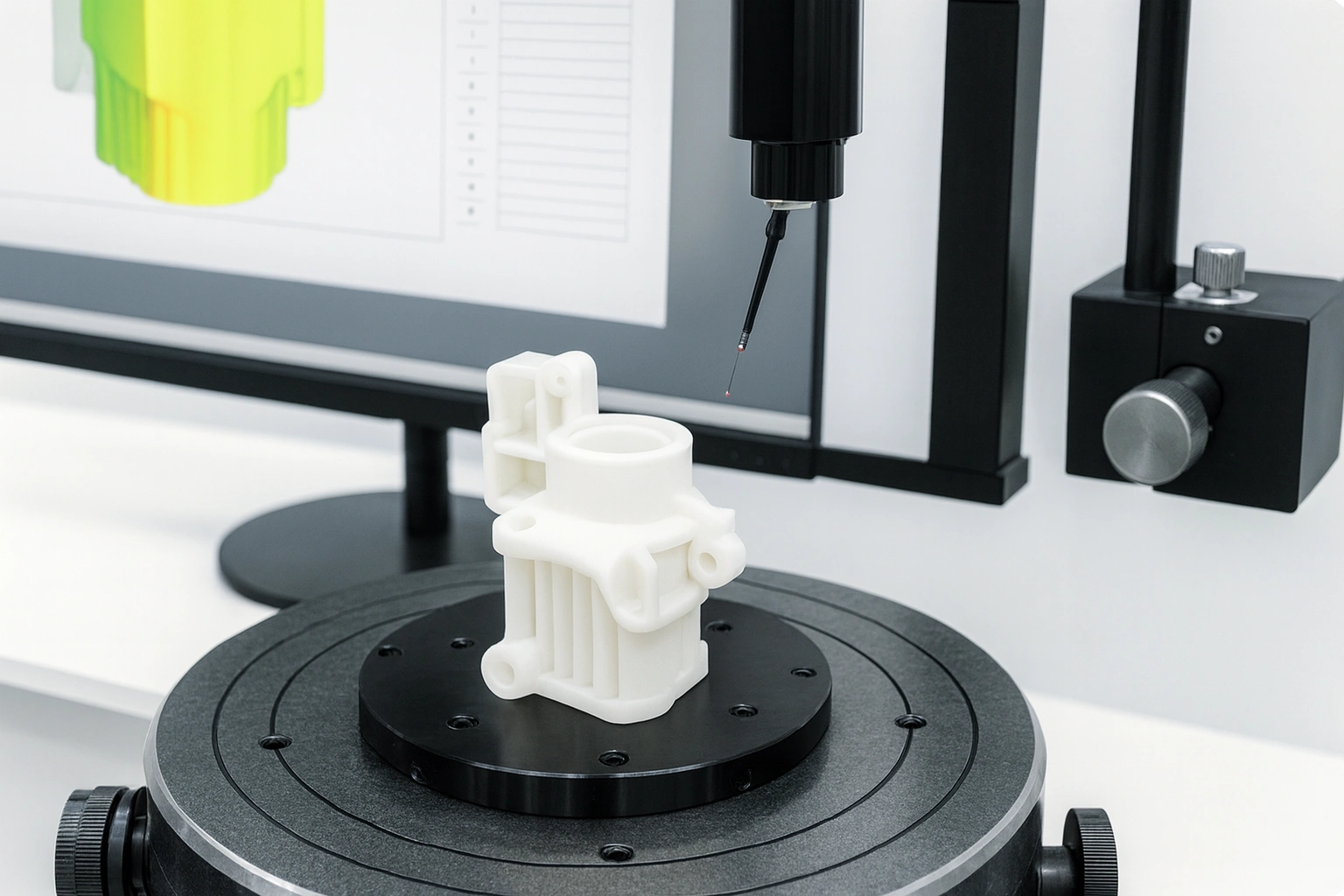

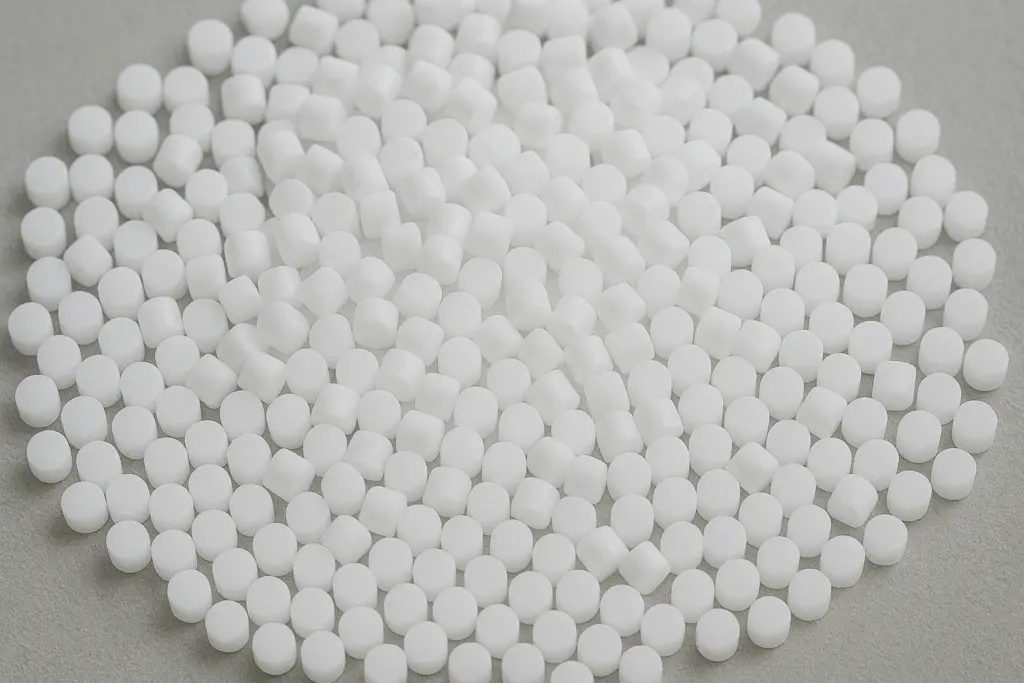

Robotika offers advanced low-volume manufacturing solutions using a combination of CNC machining, rapid prototyping, and specialized tooling techniques. We work with a wide range of materials, including thermoplastics such as ABS, PC, PA, and PP, high-performance plastics like PEEK and PPS, as well as metals including aluminum and engineering-grade alloys for CNC machining. We provide a variety of surface finishing options, including polishing, anodizing, bead blasting, laser engraving, and painting. Our CNC machining services can achieve tight tolerances of up to ±0.01 mm, and we use advanced quality control methods, such as CMM inspection and digital calipers, to guarantee consistent and repeatable results across all production runs. Whether you need cosmetic finishes or precise functional features, our team ensures that your parts meet the highest standards of quality and performance.

Robotika delivers high-precision CNC machining services for custom plastic and metal parts, offering rapid turnaround, tight tolerances, and flexible production from prototyping to low-volume manufacturing.

Robotika provides rapid prototyping services with CNC precision, turning your 3D designs into functional plastic and metal parts in just days for faster product validation and market launch.

Robotika offers vacuum casting services for high-quality prototypes and low-volume plastic parts, delivering smooth surface finishes and consistent detail at a fraction of tooling costs.

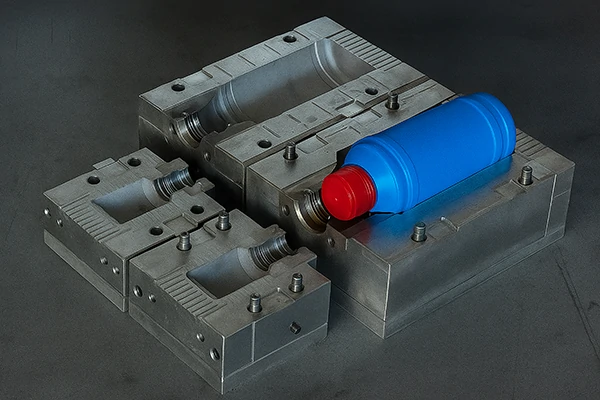

Robotika provides plastic injection molding services as part of our low-volume production solutions, enabling customers to create precise and consistent plastic parts with high repeatability.

Low-Volume Manufacturing Capabilities

Maximum Build Size

Maximum single print size of 300mm × 300mm × 400mm, ideal for small to medium-sized molds or products.

Material Compatibility

Capable of printing PLA, ABS, PETG, Nylon (PA), TPU (flexible materials), and photosensitive resin, meeting various injection mold testing and product needs.

Molding Precision

Our standard tolerance is controlled within ±0.1mm, ensuring high precision for lightweight and durable plastic components.

Surface Finishing Options

We support texturing, polishing, silk-screen printing, UV coating, and electroplating for enhanced aesthetics and functionality.

Delivery Time

Our standard CNC Machining lead time is 7-15 days, with expedited services available for urgent projects.

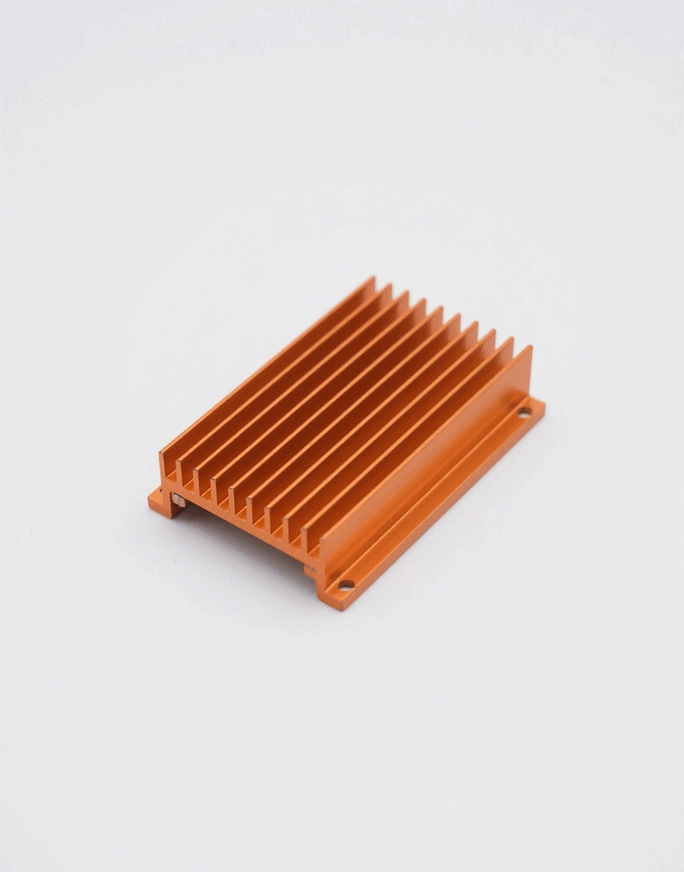

Our Low-Volume Manufacturing Products We have Manufactured

Low-Volume Manufacturing Tolerance

| Part Type | Tolerance Range |

|---|---|

| CNC Milling | ±0.02 mm – ±0.05 mm |

| CNC Turning | ±0.01 mm – ±0.03 mm |

| CNC Grinding | ±0.005 mm – ±0.01 mm |

| CNC EDM / Wire Cutting | ±0.01 mm – ±0.02 mm |

| General Plastics (ABS, PP, PC, PA, etc.) | ±0.05 mm – ±0.10 mm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Low-Volume Manufacturing Materials

Aluminum (6061, 7075, 2024)

Aluminum is one of the most popular materials for low-volume CNC machining because it combines lightweight, high strength, and excellent machinability. It allows for cost-effective production of parts with complex geometries, making it ideal for prototypes and small batches. Aluminum components are widely used in aerospace brackets, automotive housings, consumer electronics, and medical devices where performance and weight reduction are critical. Its versatility and surface treatment options make it suitable for both functional and cosmetic parts.

Mill Lead Time: As fast as 3 days

Finishes: Raw, anodized, bead blasted, polished

Stainless Steel (303, 304, 316, 17-4PH)

Stainless steel is highly valued for low-volume CNC machining thanks to its corrosion resistance, strength, and durability. It is an excellent material for small-batch parts that must withstand harsh environments, chemical exposure, or high mechanical stress. Common applications include surgical tools, marine fittings, food-processing equipment, and precision mechanical components. CNC machining ensures tight tolerances and repeatability, even in small runs, making stainless steel a reliable choice for industries where quality cannot be compromised.

Mill Lead Time: 5–7 days

Finishes: Raw, passivated, polished, bead blasted

Carbon Steel (1018, 1045)

Carbon steel is a cost-effective material for low-volume manufacturing, offering excellent machinability and mechanical strength. It is commonly used in structural components, shafts, gears, and fixtures where durability and toughness are required. CNC machining ensures precise dimensions and stable performance, even in small batches. Carbon steel is widely applied in automotive, industrial equipment, and tooling applications where high strength at a competitive price is critical. Heat treatment and surface finishes can further enhance its performance.

Mill Lead Time: 5–7 days

Finishes: Raw, heat-treated, painted, plated

Brass & Copper

Brass and copper are excellent materials for low-volume CNC machining due to their superior machinability, conductivity, and attractive appearance. They are frequently used in electrical connectors, decorative parts, heat exchangers, and precision fluid-handling components. Small-batch production of brass or copper parts ensures cost efficiency while maintaining high precision for both functional and aesthetic applications. These materials are ideal when both performance and appearance are equally important, especially in consumer and industrial products.

Mill Lead Time: As fast as 3 days

Finishes: Raw, polished, plated, brushed

Titanium (Grade 2, Grade 5)

Titanium is a premium choice for low-volume CNC machining, offering an unmatched balance of high strength, low weight, and corrosion resistance. It is frequently applied in aerospace engine parts, medical implants, and performance automotive components, where durability and weight savings are critical. Though more challenging to machine, CNC technology allows tight tolerances and repeatability, even for small batches. Titanium’s performance in extreme conditions makes it one of the best materials for industries requiring reliability and innovation.

Mill Lead Time: 7–10 days

Finishes: Raw, polished, bead blasted, anodized

ABS (Acrylonitrile-Butadiene-Styrene)

ABS is a widely used thermoplastic for low-volume CNC machining because of its toughness, impact resistance, and ease of processing. It is ideal for rapid prototyping and functional parts requiring both durability and precision. ABS is commonly applied in automotive dashboards, electronic housings, appliance covers, and consumer product prototypes. Its balanced performance makes it one of the most cost-effective materials for design validation and small-batch manufacturing. Surface finishing further improves cosmetic appeal.

Mill Lead Time: As fast as 3 days

Finishes: Raw, painted, polished, textured

PP

PP is a lightweight, chemical-resistant, and flexible material well-suited for low-volume CNC machining. It is often used in lab equipment, packaging prototypes, and industrial components that must resist chemicals and wear. With stable processing properties, PP allows for cost-effective small-batch production while maintaining functionality. It is an excellent choice for fluid-handling parts, storage containers, and consumer goods. Low-volume CNC machining of PP provides flexibility for testing designs before committing to high-volume production.

Mill Lead Time: 3–5 days

Finishes: Raw, polished, textured

PC

PC is an impact-resistant plastic with excellent optical clarity, making it an ideal option for CNC-machined prototypes and low-volume production. It is often applied in protective covers, transparent housings, lenses, and industrial shields that require both toughness and transparency. CNC machining ensures tight tolerances and precise detailing for functional and aesthetic parts. PC is widely used in consumer electronics, automotive lighting, and medical devices, offering a balance of strength and visual performance.

Mill Lead Time: 3–5 days

Finishes: Raw, polished, painted, vapor-smoothed

Nylon (PA6, PA66)

Nylon is a durable engineering plastic offering excellent wear resistance and mechanical strength. It is suitable for low-volume CNC machining of functional prototypes and end-use parts such as gears, bushings, bearings, and industrial fittings. Nylon’s toughness and machinability make it ideal for mechanical applications requiring precision and load-bearing capability. It is widely used in automotive, industrial, and consumer products where lightweight but strong components are required.

Mill Lead Time: 3–5 days

Finishes: Raw, machined, polished, painted

POM (Delrin® / Acetal)

POM is a high-stiffness engineering plastic ideal for low-volume CNC machining, offering excellent dimensional stability, wear resistance, and low friction. It is frequently used for gears, automotive components, and consumer products requiring high precision and smooth operation. CNC machining of POM ensures consistent results even for tight tolerance parts in small batches. Its combination of strength and machinability makes it a preferred choice for mechanical prototypes and small-scale production runs.

Mill Lead Time: 3–5 days

Finishes: Raw, polished, machined surface

PEEK (Polyetheretherketone)

PEEK is a top-tier engineering plastic for low-volume CNC machining, offering outstanding strength, chemical resistance, and thermal stability. It maintains excellent mechanical properties even under extreme conditions, making it ideal for aerospace, automotive, and medical industries. Common applications include engine components, implants, and oil & gas parts. Although more expensive, PEEK delivers unmatched durability and reliability, making it suitable for critical parts where performance cannot be compromised.

- Mill Lead Time: 5–7 days

- Finishes: Raw, polished, machined

PPS

PPS is highly resistant to heat, chemicals, and wear, making it an excellent material for small-batch CNC machining. It is widely used in pump parts, automotive components, and electronic connectors that operate in demanding environments. PPS maintains dimensional stability and strength even at elevated temperatures, making it an ideal choice for precision parts in industrial and electrical sectors. Low-volume CNC machining provides flexibility for prototyping and early-stage product validation.

Mill Lead Time: 5–7 days

Finishes: Raw, polished, painted

Ultem (PEI – Polyetherimide)

Ultem is a high-performance plastic valued for its strength, lightweight properties, and flame resistance. It is commonly used in aerospace interiors, electronic housings, and medical devices requiring reliability and safety. CNC machining allows Ultem parts to be produced with precision and repeatability in low-volume runs. Its excellent mechanical properties and resistance to heat make it one of the most versatile advanced plastics for critical industries.

Mill Lead Time: 5–7 days

Finishes: Raw, machined, polished

PTFE (Teflon®)

PTFE is an outstanding material for low-volume CNC machining, offering unparalleled chemical resistance, low friction, and thermal stability. It is often applied in sealing components, insulating parts, fluid-handling systems, and medical equipment where harsh operating environments exist. PTFE’s machinability ensures smooth finishes and reliable performance in prototypes and small batches. Its unique properties make it a go-to choice for industries requiring long-lasting and chemically inert components.

Mill Lead Time: 5–7 days

Finishes: Raw, polished, machined

Finishing Options for Low-Volume Manufacturing

| Name | Description | Can Be Applied with | Applicable Materials |

|---|---|---|---|

Anodizing (Type II, III)

Anodizing (Type II, III)

|

Creates a durable, corrosion-resistant oxide layer, available in various colors; enhances hardness. | CNC Milling, CNC Turning | Aluminum, Titanium |

Bead Blasting

Bead Blasting

|

Produces a uniform matte or satin surface finish; removes machining marks. | CNC Milling, CNC Turning | Aluminum, Stainless Steel, Plastics |

Polishing

Polishing

|

Provides a smooth, reflective surface; used for aesthetic or functional parts. | CNC Milling, CNC Turning, Grinding | Metals, Plastics |

Powder Coating

Powder Coating

|

Applies a strong, protective coating available in different colors; improves wear resistance. | CNC Milling, CNC Turning | Steel, Aluminum, Stainless Steel |

Electropolishing

Electropolishing

|

Improves smoothness, reduces friction, and enhances corrosion resistance. | CNC Machining, Grinding | Stainless Steel, Titanium |

Passivation

Passivation

|

Chemical treatment that removes free iron, improving corrosion resistance. | CNC Machining, Turning | Stainless Steel |

Plating (Nickel, Zinc, Chrome)

Plating (Nickel, Zinc, Chrome)

|

Adds a protective or decorative metal layer; enhances wear and corrosion resistance. | CNC Milling, CNC Turning | Steel, Copper, Brass, Aluminum |

Painting / Powder Spray

Painting / Powder Spray

|

Provides customized color, appearance, and protection. | CNC Milling, CNC Turning | Metals, Plastics |

Laser Marking

Laser Marking

|

Permanent marking for logos, serial numbers, or identification. | CNC Machining | Metals, Some Plastics |

Brushing

Brushing

|

Creates a linear texture for cosmetic and anti-reflective purposes. | CNC Milling, CNC Turning | Aluminum, Stainless Steel |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Low-Volume Manufacturing Design Guide

In this guide to CNC machining, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

Low-Volume Manufacturing Service FAQs

What is the typical order quantity for low-volume CNC machining?

We usually handle orders from 50 to 5,000 parts, but smaller or larger batches can also be discussed.

How fast can you deliver prototypes or small-batch parts?

Standard lead time is 3–7 days for prototypes, and 1–3 weeks for low-volume production runs, depending on part complexity.

Do you provide material certifications for metal and plastic parts?

Yes, we can supply full material traceability and certifications (e.g., RoHS, REACH, ISO) upon request.

Can I order multiple materials or finishes in one batch?

Absolutely. We can combine different materials and finishing options within the same low-volume order.

What is your tolerance capability for CNC-machined parts?

For metals, we can achieve up to ±0.01 mm, and for plastics, typically ±0.05 mm, verified by CMM inspection.

Do you support design changes during production?

Yes, one of the benefits of low-volume manufacturing is flexibility. We can adjust designs before committing to larger runs.

Can you ship internationally for small orders?

Yes, we regularly ship prototypes and small-batch orders worldwide via express or freight options.

Low-Volume CNC Manufacturing Related Resource

Are You Looking for CNC Low-Volume Manufacturing in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.