Custom CNC Milling Services

We offer high-precision CNC milling services, from rapid prototypes to full-scale production, with turnaround times as fast as 5 days.

- Tolerances as tight as ±0.008 mm

- Custom CNC milled parts tailored for both prototyping and production applications.

- 100+ plastic and metal materials available

- ISO 9001:2015 Certified

Start a New CNC Milling Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable CNC Milling Services Provider from China

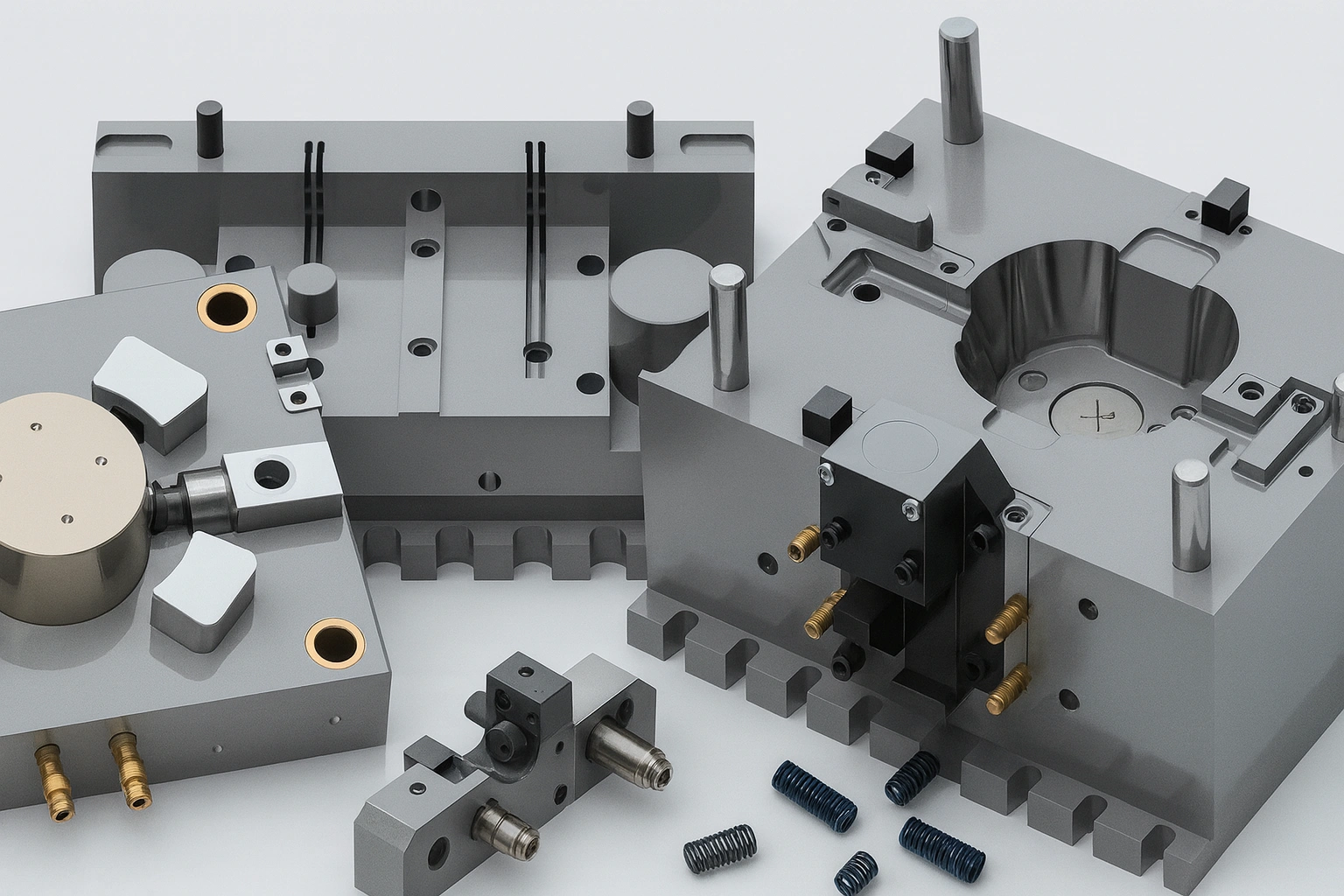

Robotika is a professional CNC milling manufacturer in China. With over a decade of manufacturing experience, Robotika produces more than 100,000 CNC-machined parts annually for customers worldwide. Equipped with advanced 3-, 4-, and 5-axis CNC milling centers, we can efficiently deliver both rapid prototypes and large-scale production orders. Our integrated turning-milling capabilities, coupled with strict quality control, ensure every part meets the highest standards of accuracy and surface finish. From providing DFM feedback to selecting the right materials and machining strategies, our team helps prevent costly errors and ensures your parts are produced with exceptional precision and consistency. Whether you need complex geometries, tight tolerances, or flawless cosmetic finishes, our CNC milling services deliver speed, reliability, and repeatability.

Our services support industries such as automotive, aerospace, electronics, medical devices, and industrial equipment, earning long-term trust from clients ranging from startups to global enterprises. By combining advanced equipment, skilled technicians, and a commitment to quality, we provide dependable CNC solutions that meet diverse application needs.

Our CNC Milling Capabilities

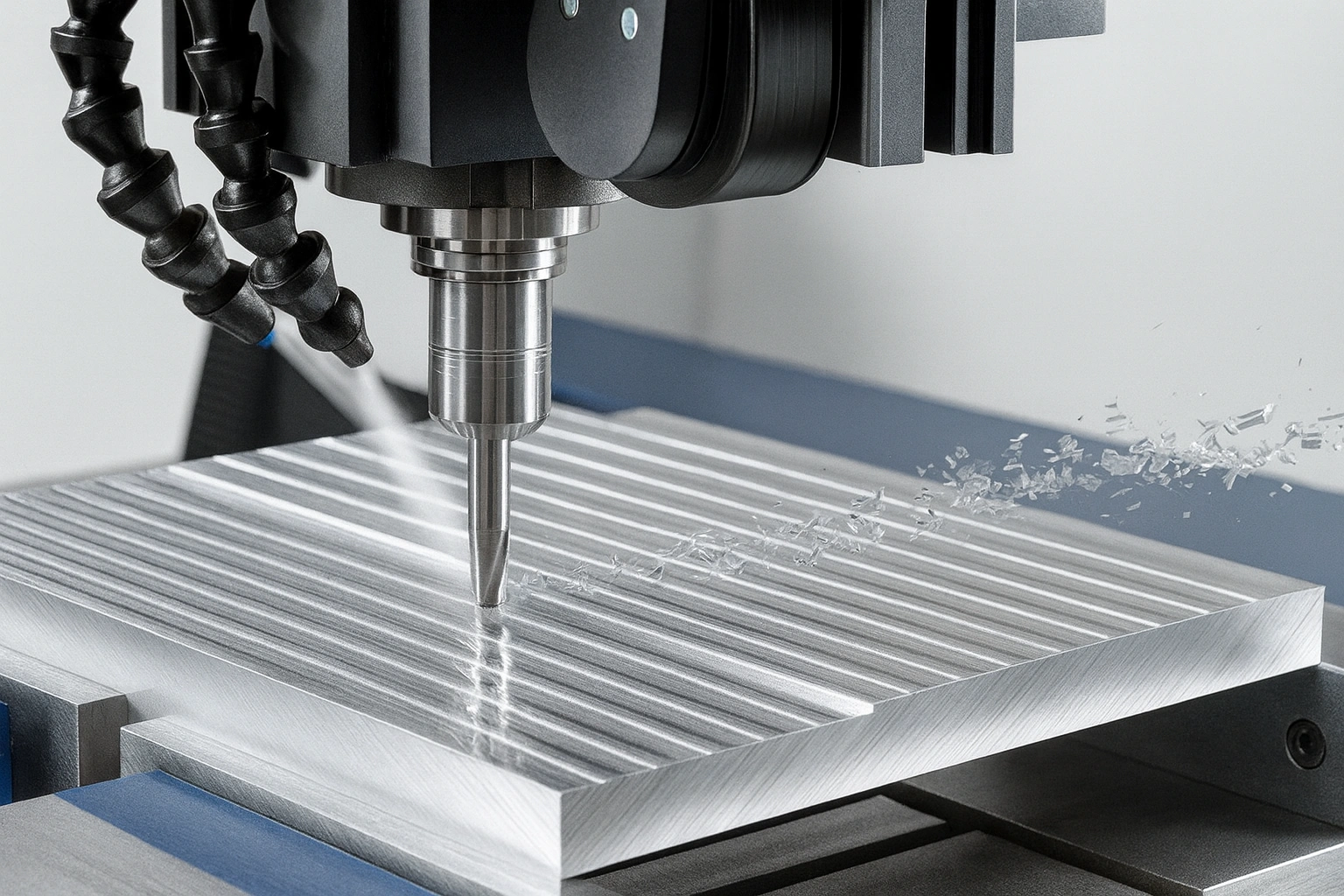

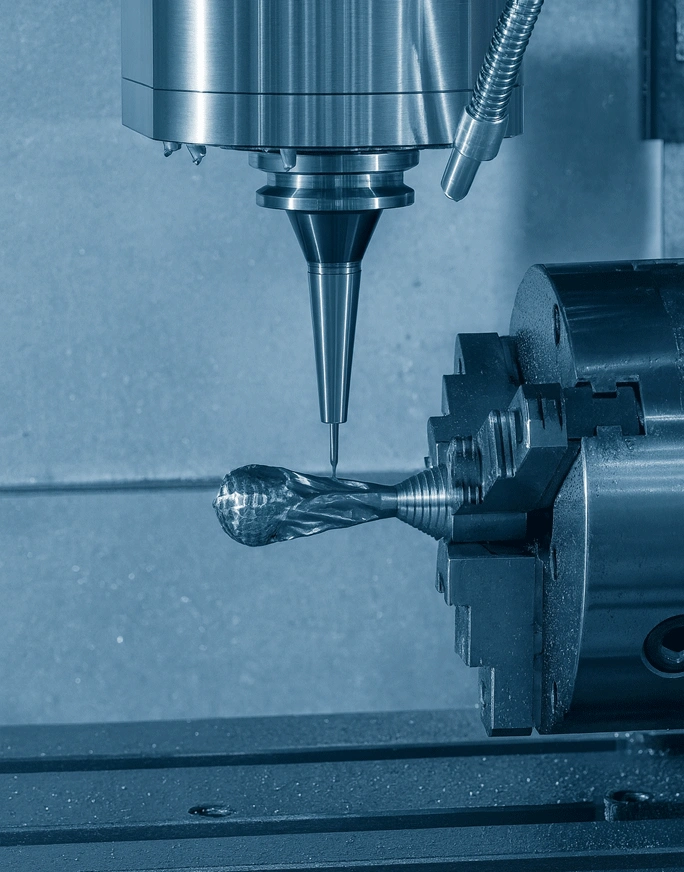

Robotika provides advanced CNC milling solutions featuring multi-axis machining, CAD/CAM programming, high-speed machining (HSM), and precision tooling & fixturing. Our facility is equipped with state-of-the-art 3-, 4-, and 5-axis CNC milling centers, enabling us to produce complex geometries with exceptional accuracy in a single setup. We work with a wide range of materials, including aluminum, stainless steel, brass, copper, titanium, and engineering plastics such as PEEK, Delrin, and ABS, meeting the demands of diverse industries from aerospace to consumer electronics. Our operations consistently achieve tight tolerances down to ±0.01 mm for critical features. Each part undergoes rigorous dimensional inspection with automated CMM (Coordinate Measuring Machine) verification, guaranteeing quality and repeatability from prototype to mass production.

Produce complex geometries and precision features in a single setup with our advanced 3-, 4-, and 5-axis CNC milling capabilities.

Transform your designs into flawless parts through optimized toolpaths and efficient CNC programming.

Accelerate production while maintaining exceptional accuracy and surface finishes for tight-deadline projects.

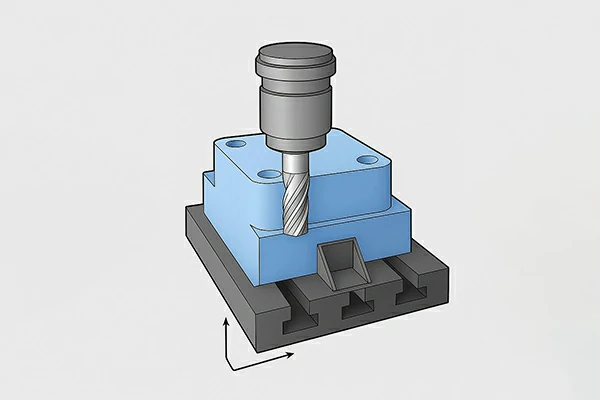

Ensure repeatable accuracy and stability with custom-engineered fixtures and high-quality tooling solutions.

CNC Milling Capabilities

Machining Size

Maximum machining size up to 1000mm × 600mm × 500mm, suitable for large-sized parts. Minist machining size up to 400mm × 300mm × 250mm, suitable for small to medium-sized precision parts.

Material Compatibility

Capable of machining aluminum, stainless steel, brass, copper, carbon steel, and engineering plastics (POM, ABS, Nylon, PEEK, etc.), meeting various industrial and custom production needs.

Machining Accuracy

Standard tolerance controlled within ±0.01mm, ensuring high precision for mechanical components, electronic parts, and industrial applications.

Surface Finishing Options

Supports anodizing, polishing, sandblasting, powder coating, electroplating, laser engraving, and more for enhanced durability and aesthetics.

Delivery Time

Standard CNC machining lead time is 5-7 days, with expedited service available for urgent projects.

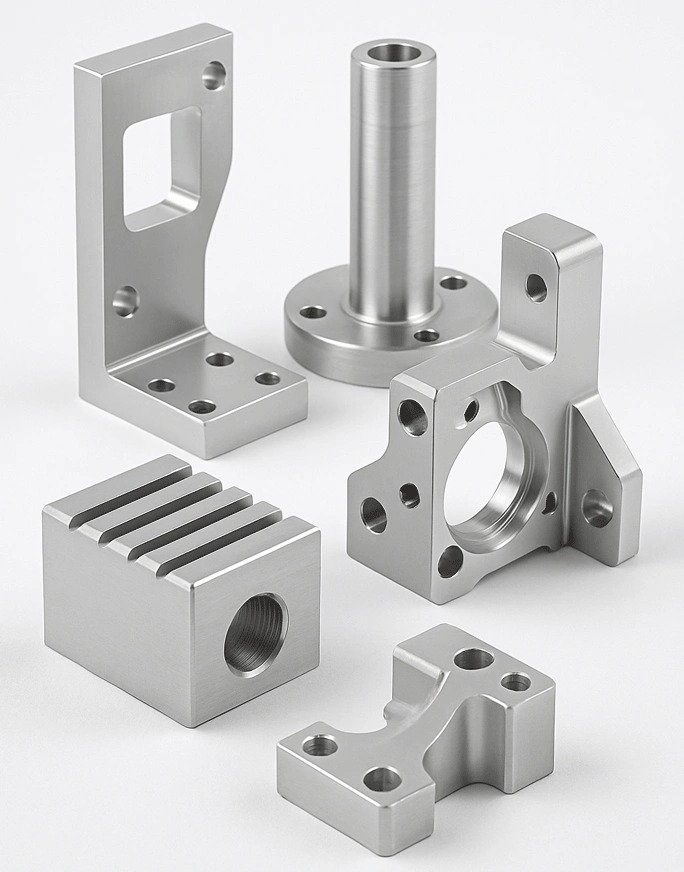

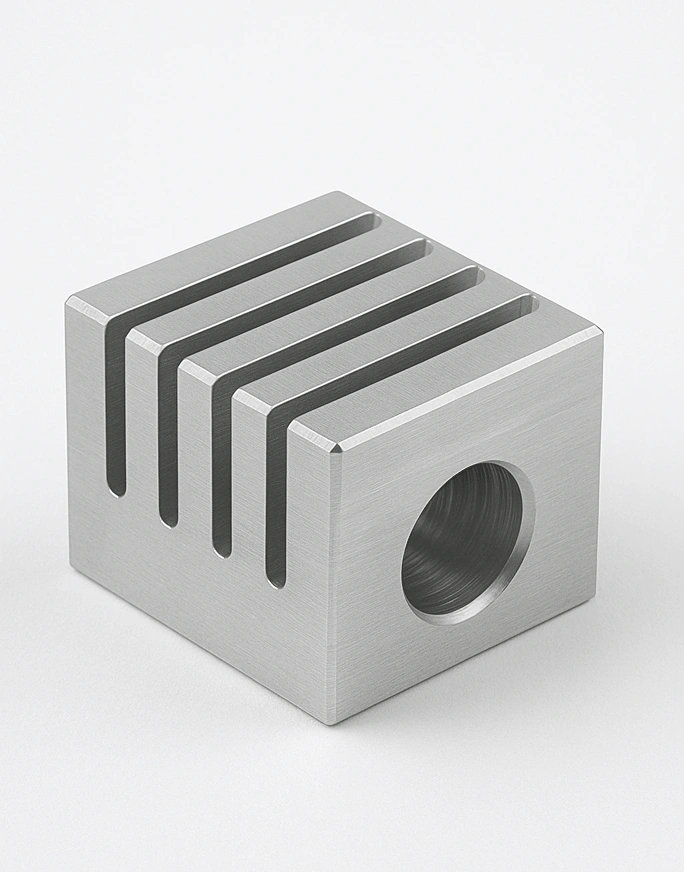

Our Latest CNC Milling Products We have Manufactured

CNC Milling Tolerance

| Part Type | Tolerance Range |

|---|---|

| Aluminum Alloys | ±0.02 mm – ±0.05 mm |

| Stainless Steel | ±0.03 mm – ±0.05 mm |

| Brass / Copper | ±0.02 mm – ±0.04 mm |

| Titanium Alloys | 0.03 mm – ±0.05 mm |

| Engineering Plastics (ABS, POM, PEEK) | ±0.05 mm – ±0.10 mm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

CNC Milling Materials

Aluminum alloys

Aluminum alloys are ideal for CNC milling due to their excellent machinability, light weight, and high strength-to-weight ratio. They offer good corrosion resistance and can achieve tight tolerances with smooth surface finishes. In CNC milling, aluminum alloys are widely used for aerospace components, automotive engine parts, electronic housings, and industrial fixtures. For example, 6061 is commonly used for precision brackets, while 7075 is favored for high-strength structural parts.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, anodized, bead blasted, polished.

Stainless steel

Stainless steel is well-suited for CNC milling due to its high strength, corrosion resistance, and ability to maintain dimensional stability under stress. It delivers excellent wear resistance, making it ideal for functional and long-lasting parts. In CNC milling, stainless steel is widely used for medical instruments, food processing equipment, aerospace fittings, and industrial machine components. For example, 304 stainless steel is common for sanitary parts, while 316 is preferred for marine applications.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, brushed, polished, passivated.

Carbon steel

Carbon steel is a great choice for CNC milling due to its high strength, toughness, and cost-effectiveness. It offers good machinability, especially in low- and medium-carbon grades, and can be heat-treated for enhanced hardness. In CNC milling, carbon steel is widely used for gears, shafts, fixtures, and heavy-duty structural parts. For example, 1018 carbon steel is common for precision jigs, while 1045 is preferred for wear-resistant machine components.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, painted, powder coated, plated.

Brass

Brass is ideal for CNC milling due to its excellent machinability, corrosion resistance, and ability to achieve precise dimensions with smooth surface finishes. It offers good thermal and electrical conductivity, making it suitable for both functional and decorative parts. In CNC milling, brass is widely used for valves, fittings, electronic connectors, and decorative hardware. For example, C360 brass is popular for precision gears and custom architectural components.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, polished, plated, brushed.

Copper

Copper is well-suited for CNC milling due to its excellent thermal and electrical conductivity, corrosion resistance, and ability to achieve precise, smooth finishes. It is easy to machine and ideal for both functional and aesthetic applications. In CNC milling, copper is commonly used for heat exchangers, electrical busbars, conductive terminals, and precision plumbing components. For example, pure copper is preferred for high-performance heat sinks and custom electrical connectors.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, polished, plated.

Titanium Alloys

Titanium alloys are ideal for CNC milling due to their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. They maintain high performance under extreme temperatures and stress, making them suitable for critical applications. In CNC milling, titanium alloys are widely used for aerospace structural parts, medical implants, high-performance automotive components, and marine hardware. For example, Grade 5 (Ti-6Al-4V) is preferred for aircraft brackets and surgical tools.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, polished, bead blasted, anodized.

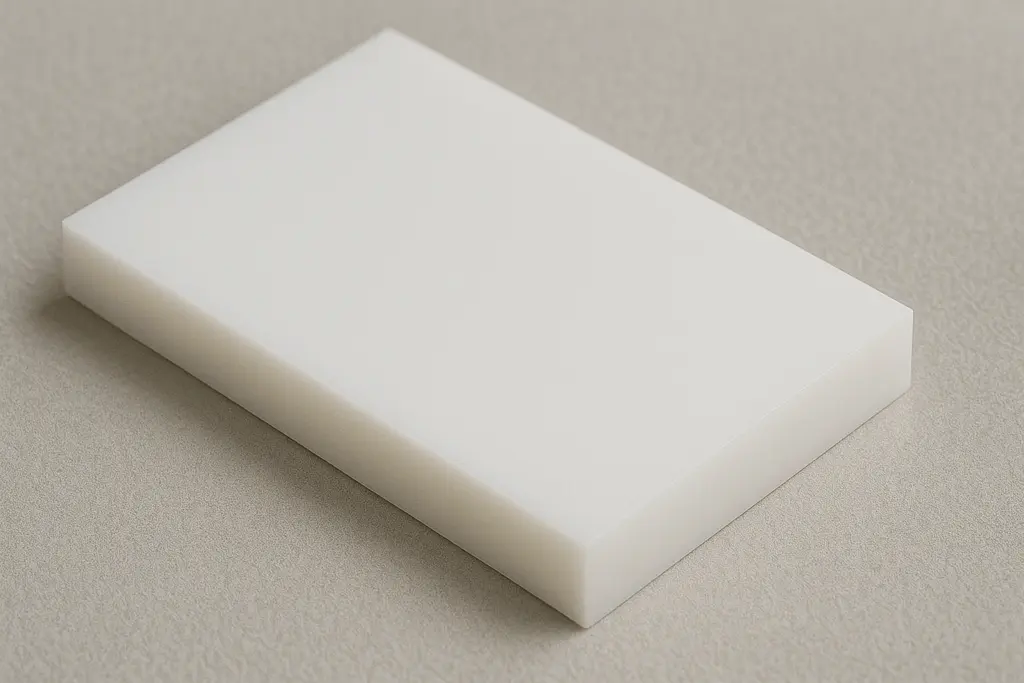

ABS

ABS (Acrylonitrile-Butadiene-Styrene) is ideal for CNC milling due to its excellent mechanical strength, impact resistance, and ease of machining at low processing temperatures. It is suitable for producing complex shapes with high dimensional accuracy. In CNC milling, ABS is widely used for automotive dashboards, electronic device housings, appliance covers, and prototypes requiring durability and fine details.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, painted, bead blasted, polished.

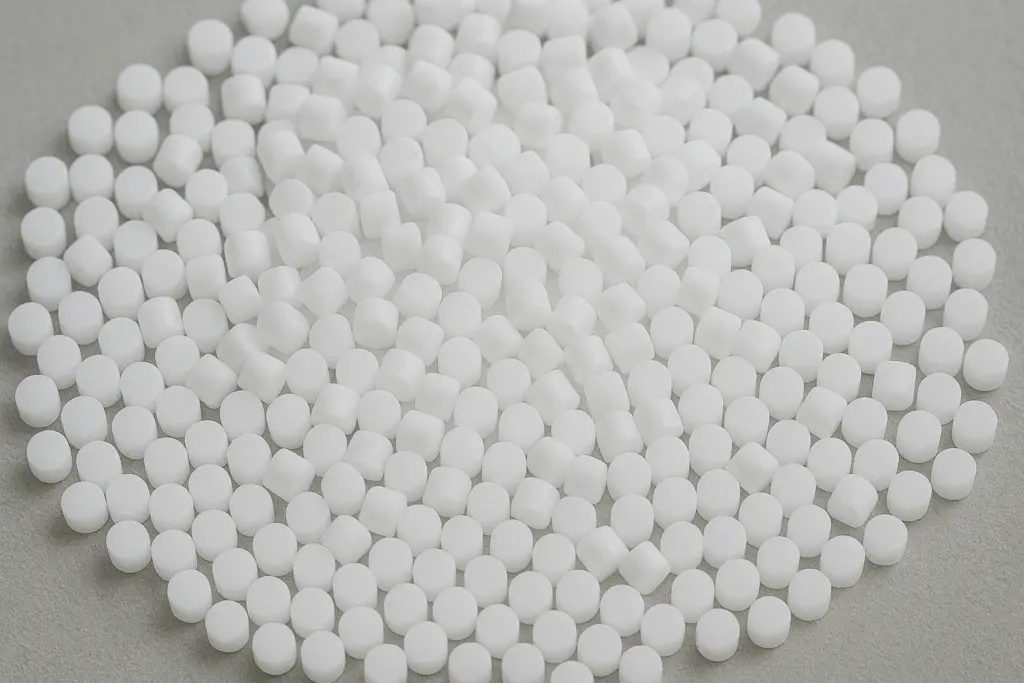

POM

POM (Delrin / Acetal) is ideal for CNC milling due to its high stiffness, low friction, excellent wear resistance, and dimensional stability. It machines cleanly without chipping, making it suitable for precision parts. In CNC milling, POM is widely used for gears, bearings, bushings, rollers, and precision mechanical components. For example, Delrin is preferred for high-accuracy gear wheels and custom jigs.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, polished, machined.

Nylon (PA6, PA66)

Nylon (PA6, PA66) is well-suited for CNC milling due to its high wear resistance, toughness, and excellent mechanical strength. It offers low friction and good chemical resistance, making it ideal for durable, functional parts. In CNC milling, nylon is widely used for gears, pulleys, bushings, and structural components. For example, PA66 is preferred for high-load industrial gears, while PA6 is common in machinery spacers.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, polished, machined.

Polycarbonate (PC)

Polycarbonate (PC) is ideal for CNC milling due to its high impact resistance, toughness, and excellent dimensional stability. It machines cleanly and can maintain optical clarity or be tinted for functional aesthetics. In CNC milling, PC is widely used for protective covers, machine guards, optical components, and electronic housings. For example, it is often chosen for transparent safety shields and precision light diffusers.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, polished, machined.

Acrylic (PMMA)

Acrylic (PMMA) is ideal for CNC milling due to its excellent optical clarity, weather resistance, and ease of machining into precise shapes. It can be polished to a glass-like finish, making it suitable for aesthetic and functional parts. In CNC milling, PMMA is widely used for display panels, light guides, protective covers, and signage. For example, it is often chosen for transparent machine guards and custom LED light diffusers.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, polished, machined.

PEEK

PEEK (Polyether Ether Ketone) is ideal for CNC milling due to its exceptional mechanical strength, high-temperature resistance, and outstanding chemical stability. It maintains precision under extreme conditions, making it suitable for high-performance applications. In CNC milling, PEEK is widely used for aerospace components, medical implants, semiconductor parts, and industrial equipment. For example, it is often chosen for surgical instrument handles and precision pump components.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, polished, machined.

PTFE (Teflon)

PTFE (Teflon) is ideal for CNC milling due to its exceptional chemical resistance, low friction coefficient, and excellent temperature tolerance. It machines smoothly and is perfect for parts requiring non-stick properties and high durability. In CNC milling, PTFE is widely used for seals, gaskets, insulators, and chemical handling components. For example, it is often chosen for custom valve seats and electrical insulation parts.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, machined, polished.

PEI (Ultem)

PEI (Ultem) is ideal for CNC milling due to its high strength, excellent thermal stability, and inherent flame resistance. It maintains dimensional accuracy under high temperatures and heavy loads, making it suitable for demanding applications. In CNC milling, PEI is widely used for aerospace interior components, medical device housings, and high-performance electrical insulators. For example, it is often chosen for aircraft seating frames and sterilizable surgical equipment.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, machined, polished.

PVDF

PVDF (Polyvinylidene Fluoride) is ideal for CNC milling due to its excellent chemical resistance, UV stability, and mechanical strength. It machines cleanly and maintains performance in harsh outdoor and corrosive environments. In CNC milling, PVDF is widely used for chemical processing components, pump parts, valve bodies, and semiconductor equipment. For example, it is often chosen for custom fluid handling fittings and corrosion-resistant housings.

- Mill Lead Time: As fast as 3 days.

- Finishes: Raw, machined, polished.

Finishing Options for CNC Milling

| Name | Applicable Materials | Colors | Can Be Applied with |

|---|---|---|---|

Texturing (MT/VDI Standard)

Texturing (MT/VDI Standard)

|

Aluminum, Stainless Steel, Steel, Copper | Matte, Satin | Anodizing, Painting |

Polishing

Polishing

|

Aluminum, Stainless Steel, Brass, Copper | High Gloss, Mirror Finish | Electroplating, UV Coating |

Silk-Screen Printing

Silk-Screen Printing

|

Aluminum, Stainless Steel | Custom Colors | Painting, Spray Coating |

Pad Printing

Pad Printing

|

Aluminum, Stainless Steel | Custom Colors | Painting, Spray Coating |

Laser Engraving

Laser Engraving

|

Aluminum, Stainless Steel, Brass, Titanium | Natural Metal, Black, White | Anodizing, Polishing |

UV Coating

UV Coating

|

Aluminum, Stainless Steel, Brass | Glossy, Matte | Polishing, Painting |

Electroplating (Vacuum Metallization)

Electroplating (Vacuum Metallization)

|

Steel, Brass, Copper | Chrome, Gold, Silver | Polishing, Texturing |

Painting & Spray Coating

Painting & Spray Coating

|

Aluminum, Stainless Steel | Custom Colors | Polishing, Sandblasting |

Hot Stamping

Hot Stamping

|

Aluminum, Stainless Steel | Gold, Silver, Metallic | Painting, Spray Coating |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

CNC Milling Design Guide

In this guide to CNC milling, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

CNC Milling Service FAQs

What’s your typical lead time for CNC milling orders

Prototypes can be delivered in as fast as 3–5 days, and production runs usually take 1–2 weeks depending on complexity and quantity.

What file formats do you accept for quotes?

We accept STEP, IGES, X_T, STL, and other common 3D CAD files, plus PDF drawings if available.

What’s your minimum order quantity (MOQ)?

We have no strict MOQ — from a single prototype to large-scale production, we can handle it.

Can you work with my supplied material?

Yes, we can machine with customer-supplied materials if they meet our quality and processing requirements.

How do you ensure the quality of my CNC-milled parts?

All parts are inspected with precision equipment, including CMM, calipers, and gauges, before shipment.

Do you provide surface finishing services?

Yes, we offer anodizing, powder coating, bead blasting, polishing, plating, and more.

Can you meet tight tolerances for my project?

Yes, we can achieve tolerances as tight as ±0.01 mm, depending on material and part geometry.

CNC Milling Related Resource

Are You Looking for CNC Milling Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.