CNC Manufacturing for Communication Solutions

At Robotika, we provide high-quality CNC machining for the communication industry, with rapid prototype delivery in as fast as 7 days.

- 10+ years of CNC manufacturing experience in communication

- rapid prototyping and on-demand production

- tolerances as tight as +/- 0.001 inches

- offer a variety of materials, including metals, plastics, and composites

- 24/7 engineering support, CMM inspection & full material traceability

Start Manufacturing Your CNC Communication Parts!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

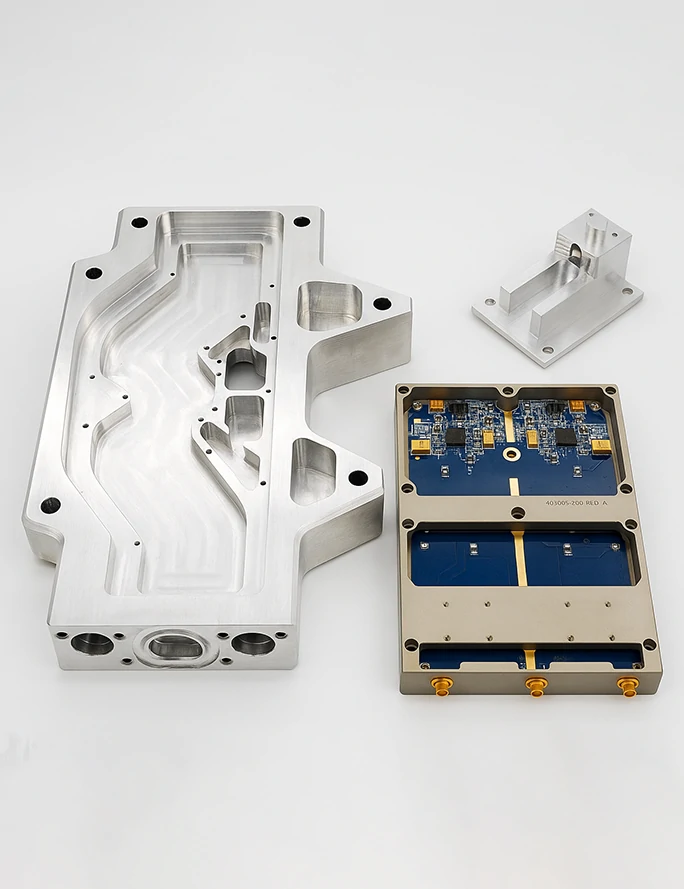

Reliable CNC Communication Parts Supplier from China

Robotika specializes in CNC manufacturing for the communication industry, delivering precision-machined parts with advanced 3-, 4-, and 5-axis CNC centers, high-speed EDM, and tight-tolerance inspection systems. We provide rapid prototyping and flexible low- to medium-volume production to meet the fast-paced demands of telecom and electronic equipment manufacturers. Our services stand out with quick-turn delivery (as fast as 1–3 days), DFM support for cost-effective production, and a wide range of metal and engineering plastic options to ensure optimal performance in communication devices and infrastructure components.

Beyond machining, Robotika offers value-added solutions including material selection guidance, custom surface finishing, and full dimensional inspection with automated CMM systems to ensure reliability and durability of every part. With more than a decade of experience and over 100,000 parts delivered annually, we proudly serve global telecom equipment companies, 5G technology providers, data center solution suppliers, and innovative startups in the communication sector.

What kind of communication parts can we make?

Robotika produces a wide range of CNC-machined components for the communication industry, including antenna housings, heat sinks, connector shells, brackets, waveguide parts, and protective enclosures. These parts are manufactured from materials such as aluminum alloys, stainless steel, copper, brass, and engineering plastics like PEEK, PPSU, and glass-filled nylon, chosen for their conductivity, strength, insulation, and flame-retardant properties. To meet performance and durability needs, we provide finishing options including anodizing, passivation, powder coating, and electropolishing. All parts are verified through automated CMM inspection and visual checks to achieve tight tolerances of up to ±0.01 mm.

- Antenna housings

- Heat sinks

- Connector shells

- Waveguide components

- Mounting brackets

- Enclosures and casings

- RF shields

- Base station frames

- Optical transceiver housings

- Cooling plates

- PCB mounting frames

- Fiber optic adapters

- Cable clamps

- Signal filter housings

- Microwave modules

- 5G small cell enclosures

- Power amplifier housings

- Communication rack panels

- Heat spreaders

- Chassis components

- Satellite terminal brackets

- Sensor housings

- Battery enclosures

- Data server brackets

Communication CNC Machining Capabilities

Supported Materials

We machine communication-grade metals and plastics, including aluminum alloys (6061, 7075), titanium (Ti-6Al-4V), stainless steel (304, 316L), PEEK, and PTFE, meeting demanding telecom and electronics standards.

Machining Accuracy

Typical tolerance within ±0.01mm ensures precise, reliable communication components.

Maximum Machining Size

Up to 1000 × 600 × 500mm, accommodating antennas, housings, and structural parts.

Surface Finishing Options

Anodizing, polishing, bead blasting, powder coating, and custom finishes available.

Delivery Time

Standard lead time 5–10 days; expedited service available for urgent projects.

Experience the boundless possibilities of customization

Enhance your communication components with precision machining and advanced surface finishes. At Robotika, we customize each part to meet your exact requirements—including material selection, geometry, and coating—ensuring performance, durability, and full compliance with industry standards.

| Name | Tolerance Range |

|---|---|

| Standard Communication Parts | ±0.2 mm to ±0.5 mm |

| Precision Communication Parts | ±0.05 mm to ±0.2 mm |

| Complex Communication Parts | ±0.1 mm to ±0.3 mm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

| Name | Description | Can Be Applied with | |

|---|---|---|---|

|

Anodizing (Type I, II, III) | Improves corrosion resistance and surface hardness, commonly used for aluminum alloys. | Antenna housings, brackets, structural supports |

|

Powder Coating | Provides a durable coating that protects against wear, chemicals, and environmental factors. | Communication enclosures, exterior panels, rack mounts |

|

Polishing | Enhances surface smoothness, reduces friction, and improves corrosion resistance. | Connector housings, guide rails, precision components |

|

Bead Blasting | Removes burrs, improves surface texture, and provides uniform matte finish. | Casings, structural parts, covers |

|

Electroplating (Nickel/Chrome) | Adds a layer of nickel or chrome to improve hardness, corrosion, and wear resistance. | Antenna brackets, connector shells, mechanical parts |

|

Passivation | Removes free iron and creates a protective oxide layer to improve corrosion resistance. | Fasteners, mounting brackets, connectors |

|

Heat Treatment / Hardening | Improves metal strength, toughness, and wear resistance. | Structural parts, gears, load-bearing components |

|

Laser Engraving / Marking | Provides permanent marking for identification, tracking, or traceability. | Serial numbers, QR codes, part labeling |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Aluminum Alloys (6061, 7075)

Aluminum alloys (6061, 7075) are lightweight yet strong, offering excellent machinability and corrosion resistance, making them ideal for CNC machining in the communication industry. They are widely used in antenna housings, heat sinks, structural brackets, and other precision components where reliable performance and weight reduction are critical. CNC machining ensures tight tolerances, smooth finishes, and consistent quality across production runs. These alloys are suitable for both prototype and volume manufacturing.

- Mill Lead Time: 3–5 days

- Finishes: Raw, anodized, bead blasted, polished

Stainless Steel (304, 316L)

Stainless steel grades 304 and 316L provide outstanding corrosion resistance, mechanical strength, and biocompatibility required by telecom and medical electronics. 304 excels in indoor chassis and mounting frames, while 316L’s molybdenum content resists chlorides in marine and chemical plants. CNC machining yields burr-free edges, precise threads, and smooth surfaces ready for IP67 sealing. Passivation and electropolishing eliminate surface contaminants, extending service life and ensuring regulatory compliance.

- Mill Lead Time: 3–5 days

- Finishes: Raw, polished, passivated, bead blasted

Titanium (Ti-6Al-4V)

Titanium (Ti-6Al-4V) offers the highest strength-to-weight ratio of any structural metal plus immunity to galvanic corrosion and extreme temperatures—ideal for aerospace telemetry, drone avionics, and MRI-compatible modules. Its stiffness stabilizes optical benches and RF connectors under shock and vibration, while non-magnetic properties preserve signal integrity. CNC machining produces complex geometries within ±0.01 mm; anodizing yields colorful, wear-resistant layers, and polishing creates ultra-smooth, low-insertion-force surfaces.

- Mill Lead Time: 5–7 days

- Finishes: Raw, anodized, polished, bead blasted

Copper Alloys

High-conductivity coppers like C110 and free-machining C360 deliver exceptional electrical and thermal performance essential for RF shields, high-speed connectors, and bus bars. C110’s 101 % IACS rating minimizes insertion loss, while C360’s machinability shortens cycle times on precision terminals. CNC machining achieves ±0.01 mm concentricity and Ra ≤ 0.4 µm surfaces; selective silver, tin, or nickel plating enhances solderability and corrosion resistance, surpassing IPC-2221 specs.

- Mill Lead Time: 3–5 days

- Finishes: Raw, polished, electroplated

PEEK

PEEK withstands continuous 250 °C temperatures, aggressive chemicals, and high radiation, making it indispensable for semiconductor wafer handlers and aerospace avionics. Its low outgassing meets NASA and FDA requirements, while dimensional stability maintains tight tolerances over wide thermal cycles. Glass- or carbon-filled grades boost stiffness and ESD protection, and CNC machining delivers complex insulators, seals, and connector housings ready for sterilization.

- Mill Lead Time: 3–5 days

- Color: Natural, black matte finish

PTFE

PTFE offers excellent chemical resistance, low friction, and high-temperature stability, making it ideal for communication CNC machining. It is widely used for insulating components, bushings, seals, and spacer parts in telecom and networking equipment. CNC machining ensures tight tolerances, smooth surfaces, and reliable performance in high-wear or high-temperature applications. PTFE’s unique properties make it perfect for parts requiring non-stick, dielectric, and thermal-resistant characteristics.

- Mill Lead Time: 3–5 days

- Color: Natural, white

ABS

ABS combines excellent impact resistance, dimensional stability, and ease of machining, making it the default choice for consumer-electronics housings, prototyping, and protective covers. Its ability to be solvent-bonded, painted, and metallized supports rapid design iterations and custom branding. Flame-retardant grades meet UL 94 V-0 requirements, while UV-stabilized variants withstand outdoor security camera enclosures without embrittlement.

- Mill Lead Time: 3 days

- Color: Black, neutral matte finish

PC

Polycarbonate delivers high impact resistance, optical clarity, and thermal stability ideal for transparent covers, display windows, and LED diffusers. Its inherent flame retardancy and electrical insulation suit power-supply covers and battery casings. Secondary hard-coating, vapor polishing, and laser welding maintain transparency while adding scratch resistance and hermetic sealing for IP-rated devices.

- Mill Lead Time: 3–5 days

- Color: Transparent, smoke, or custom

Nylon

Nylon offers high strength, wear resistance, and chemical stability, suitable for precision communication CNC components. Commonly used in gears, spacers, bushings, and insulating parts for telecom and networking equipment. CNC machining ensures accurate dimensions, smooth surfaces, and long-term durability. Its resilience under mechanical stress and thermal stability make it ideal for functional structural parts.

- Mill Lead Time: 3–5 days

- Color: Natural, black, custom

Polycarbonate Blends (PC+ABS, PC+PA)

Polycarbonate blends combine impact resistance, dimensional stability, and heat resistance, ideal for housings, enclosures, and structural panels in communication devices. CNC machining allows complex shapes, precise tolerances, and high-quality surface finishes. These blends are perfect for parts requiring toughness, thermal stability, and aesthetic surface quality simultaneously.

- Mill Lead Time: 3–5 days

- Color: Black, smoke, custom

Carbon Fiber Reinforced Plastics

CFRP combines lightweight properties with high strength, making it suitable for structural components, antenna supports, internal frames, and brackets in communication devices. CNC machining ensures precision, smooth finishes, and tight tolerances without compromising the material’s stiffness. This allows the creation of high-performance, lightweight parts for networking equipment, 5G antennas, and other demanding applications.

- Mill Lead Time: 5–7 days

- Color: Black, matte finish

Glass Fiber Reinforced Plastics

GFRP is durable, stiff, and corrosion-resistant, making it ideal for enclosures, internal supports, and protective panels in communication devices. CNC machining enables complex geometries, high precision, and consistent quality. Its excellent mechanical properties and stability under load make it a reliable material for parts that require strength without excessive weight.

- Mill Lead Time: 5–7 days

- Color: Gray, black

Hybrid Composites (CFRP + GFRP)

Hybrid composites combine the benefits of CFRP and GFRP, providing high strength, reduced weight, and excellent dimensional stability. Ideal for high-performance structural frames, precision brackets, and antenna supports in communication systems, CNC machining ensures accurate tolerances and superior surface quality. These composites are used where lightweight and high-strength properties are simultaneously required.

- Mill Lead Time: 5–7 days

- Color: Black/Gray

Communication CNC Machining FAQs

Standard lead time is 5–10 days. Rush orders can be completed in 3–5 days depending on part complexity.

We work with aluminum (6061/7075), stainless steel (304/316L), titanium (Ti-6Al-4V), copper alloys, PEEK, ABS, PC, PTFE, Nylon, and composite materials like CFRP/GFRP.

Yes! We can quote and start production from STL, STEP, or IGES files.

Yes, we can provide COC and traceability documents for metals and critical components upon request.

Provide 3D files or drawings, material specifications, quantity, desired tolerances, and surface finish requirements.

Start Your Communication CNC Machining Project Now!

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.