CNC Manufacturing for Automation

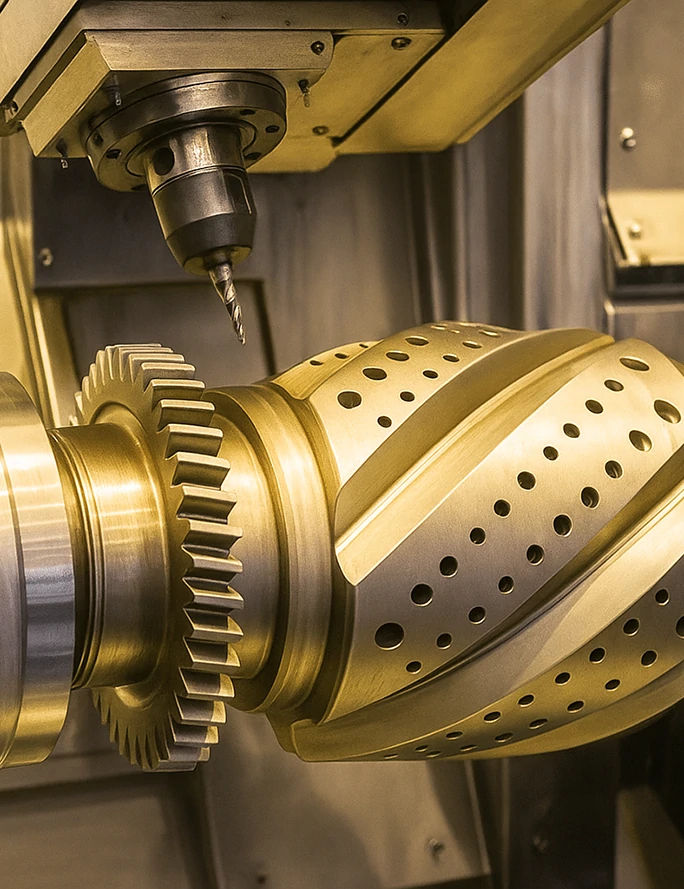

Robotika provides precision CNC machining services tailored to the electronics automation’s high standards, with rapid prototype delivery in as fast as 7 days.

- 10+ years of CNC manufacturing experience in automation

- Components with tolerances as tight as +/- 0.001 inches

- Efficient process, delivering parts within days

- Various material options including metals, plastics and composites

- 24/7 engineering support, CMM inspection & full material traceability

Start Manufacturing Your Automation Parts !

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable CNC Automation Parts Supplier from China

Robotika specializes in CNC manufacturing for automation applications, offering high-precision machining of metals, plastics, and composite materials. Leveraging a highly automated workflow, multi-stage machining, and in-house process optimization, we efficiently handle both simple and complex parts while maintaining consistent quality and tight tolerances. Our streamlined workflow ensures fast turnaround, precise tolerances, and consistent quality, helping clients accelerate product development and maintain high-performance automation systems.

Beyond standard CNC machining, we provide full support from design to production, including Design for Manufacturability (DFM) analysis, material selection guidance, and comprehensive quality inspection. With over a decade of experience and tens of thousands of parts delivered annually, Robotika serves automation equipment manufacturers, robotics developers, industrial system integrators, and advanced engineering firms worldwide, ensuring reliable, scalable, and precision-engineered components for demanding applications.

What kind of automation parts can we make?

Robotika produces a wide range of high-precision automation components, including housings, brackets, structural supports, enclosures, and guide rails for industrial robots, conveyor systems, and automated machinery. We work with metals such as aluminum alloys, stainless steel, titanium, and copper, as well as engineering plastics like PEEK, PTFE, and reinforced composites. Parts can be finished with anodizing, polishing, bead blasting, or powder coating, achieving tight tolerances down to ±0.01 mm to meet demanding automation standards.

- Robot arm brackets and joints

- Linear rails and guide blocks

- Motor mounts and gear housings

- Conveyor system components

- End effectors and grippers

- Structural supports and frames

- Sensor mounts and enclosures

- Couplings and shaft adapters

- Pneumatic and hydraulic actuator parts

- Custom automation housings and panels

- Timing pulley and sprocket mounts

- Rotary tables and indexing fixtures

- Precision clamps and vices

- Fixture plates and tooling bases

- Electronic control box housings

- High-precision sliders and carriages

- Valve manifolds and brackets

- Camera and vision system mounts

- Magnetic or mechanical actuator housings

- High-accuracy positioning stages

- Encoder mounts and supports

- Servo motor brackets and couplings

- Gearbox housings and input/output shafts

- End-of-line automation tooling

Automation CNC Machining Capabilities

Supported Materials

We specialize in machining automation-grade materials such as aluminum alloys (6061, 7075), titanium (Ti-6Al-4V), stainless steel (304, 316L), and engineering plastics like PEEK and PTFE, ideal for high-precision automation components.

Machining Accuracy

Standard tolerances within ±0.01 mm ensure reliable performance for structural frames, brackets, and mechanical assemblies.

Maximum Machining Size

Up to 1000 × 600 × 500 mm, accommodating a broad range of automation parts.

Surface Finishing Options

Anodizing, polishing, bead blasting, powder coating, and more to enhance durability and appearance.

Delivery Time

Typical lead time 5–10 days, with rush options available for urgent projects.

Experience the boundless possibilities of customization

Enhance your automation components with advanced surface finishes and precision detailing. At Robotika, we tailor each part to meet your exact specifications—including material selection, geometry, and coating—ensuring performance, reliability, and full compliance with automation standards.

| Name | Tolerance Range |

|---|---|

| Standard Automation Parts | ±0.1 mm to ±0.3 mm |

| Precision Automation Parts | ±0.02 mm to ±0.1 mm |

| Complex Automation Parts | ±0.05 mm to ±0.2 mm |

- *The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

| Name | Description | Can Be Applied with | |

|---|---|---|---|

|

Anodizing | Enhances corrosion resistance and surface hardness. | Aluminum housings, frames, structural components |

|

Polishing / Buffing | Improves surface smoothness and reduces friction. | Covers, sensor mounts, shafts |

|

Bead Blasting | Creates uniform matte texture, removes burrs. | Panels, brackets, machine casings |

|

Powder Coating | Provides durable color and chemical resistance. | External housings, protective covers |

|

Electroplating / Nickel Plating | Adds hardness, wear and corrosion resistance. | Shafts, fasteners, conductive components |

|

Painting / Color Coating | Adds aesthetic finish and protection. | Panels, casings, handles |

|

Passivation | Removes free iron and enhances corrosion resistance for stainless steel. | Stainless steel brackets, trays, cleanroom-compatible parts |

|

Electropolishing | Polishes metal for smooth surface and chemical resistance. | Stainless steel components, fluid-handling parts |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Aluminum Alloys (6061, 7075)

Aluminum alloys (6061, 7075) are standout choices for automation CNC machining, thanks to their lightweight nature (density ~2.7g/cm³) and exceptional machinability. They can be precisely milled, drilled, and cut into complex shapes while retaining structural strength—critical for automation components. 6061, with balanced strength and corrosion resistance, suits housings and brackets, while 7075’s higher tensile strength makes it ideal for transmission parts. Widely used in automation frames and precision components, they ensure high accuracy and reliable performance in industrial systems.

- Mill Lead Time: 3-5 days

- Finishes: Raw, anodized, bead blasted, polished

Stainless Steel (304, 316L)

304 and 316L stainless steels excel in automation CNC machining due to their superior corrosion resistance and chemical stability. 304, with good general corrosion resistance, is perfect for precision brackets and trays in standard environments, while 316L’s enhanced resistance to acids and saltwater suits cleanroom components and harsh settings. CNC machining delivers high dimensional accuracy and smooth surfaces, ensuring durability in automation parts like conveyor components and chemical processing fixtures.

- Mill Lead Time: 5-7 days

- Finishes: Passivation, polishing, bead blasting

Titanium (Ti-6Al-4V)

Titanium alloy Ti-6Al-4V is ideal for premium automation CNC machining, offering a rare blend of high strength, corrosion resistance, and high-temperature tolerance (up to 400°C). Its impressive strength-to-weight ratio (stronger than steel, 40% lighter) ensures lightweight yet robust components. Used for high-performance supports, fasteners, and high-heat parts in automation systems, it maintains integrity in demanding environments, making it a top choice for precision industrial applications.

- Mill Lead Time: 7-10 days

- Finishes: Raw, anodized, bead blasted

Copper & Copper Alloys

Copper and copper alloys are indispensable in automation CNC machining for their exceptional thermal conductivity—critical for heat management in industrial systems. They’re widely used for heat sinks that dissipate excess heat from machinery, contact plates ensuring reliable electrical connections, and conductive components in control systems. CNC machining enables precise cutting and milling, ensuring these parts fit seamlessly and deliver efficient heat dissipation and stable electrical performance.

- Mill Lead Time: 5-7 days

- Finishes: Polishing, electroplating

PEEK

PEEK is a high-performance plastic ideal for automation CNC machining, boasting excellent heat resistance (up to 260°C) and chemical stability—resistant to oils, solvents, and acids. This makes it perfect for robotic arm components, insulating brackets, and precision fixtures in harsh industrial environments. It maintains dimensional stability even in complex designs, ensuring consistent performance in automation systems where reliability under stress is paramount.

- Mill Lead Time: 3-5 days

- Color: Black, neutral matte finish

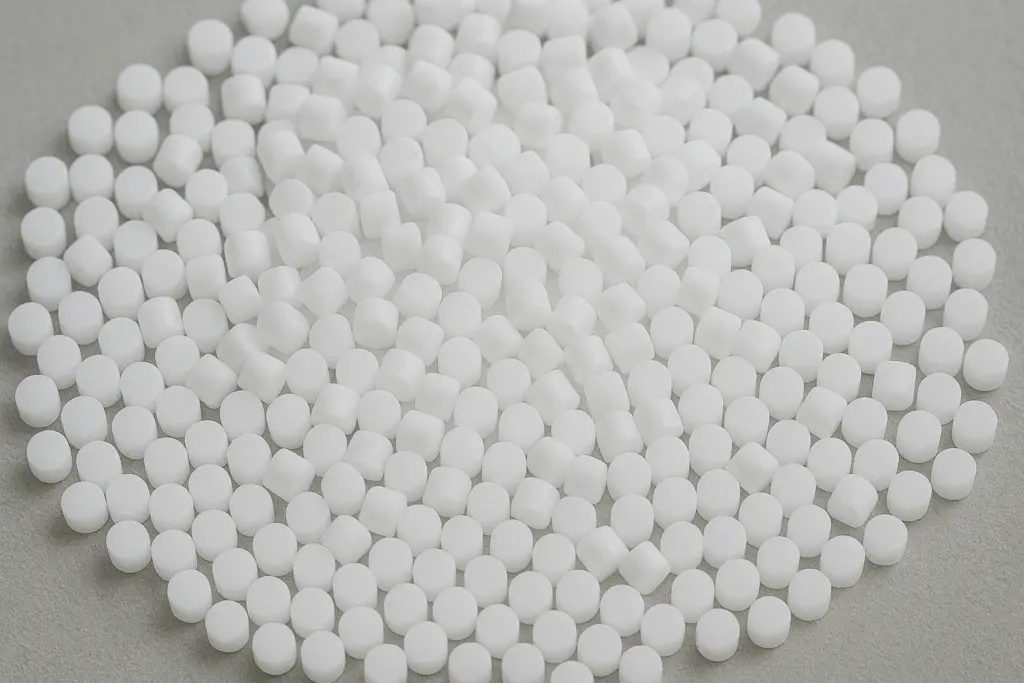

PTFE

PTFE is a standout for automation CNC machining, offering exceptional chemical resistance (inert to most substances) and a low friction coefficient—ideal for sliding guides and seals in moving automation parts. Its electrical insulation properties also suit insulating components. CNC machining ensures precise dimensions and smooth surfaces, guaranteeing reliable operation in applications like conveyor systems and fluid-handling automation equipment.

- Mill Lead Time: 3-5 days

- Color: White, neutral finish

ABS / PC

ABS and PC plastics are highly suitable for automation CNC machining, combining ease of processing with structural stability. ABS offers good impact resistance, while PC provides enhanced strength and transparency, making them ideal for test fixtures, equipment housings, and low-load brackets. CNC processing enables rapid production of complex shapes with tight tolerances, ensuring these parts integrate seamlessly into automation systems while maintaining dimensional accuracy.

- Mill Lead Time: 2-4 days

- Color: Black, transparent, or neutral matte finish

Carbon Fiber Reinforced Plastics

CFRP is a top choice for automation CNC machining, prized for its ultra-lightweight nature and high rigidity—critical for high-performance automation equipment. It’s used in robotic arm structures to reduce inertia and improve movement precision, precision supports maintaining stability, and high-accuracy positioning fixtures. CNC machining preserves its structural integrity and dimensional precision, making it indispensable for automation systems demanding both strength and precision.

- Mill Lead Time: 5-7 days

- Color: Black, matte finish

Glass Fiber Reinforced Plastics

GFRP is well-suited for automation CNC machining, offering a balance of heat resistance, chemical stability, and cost-effectiveness. It’s used for housings protecting sensitive automation components, support frames maintaining structural integrity, and guide components in machinery. CNC machining ensures precise dimensions and high durability, allowing it to handle the demands of complex automation parts in industrial environments.

- Mill Lead Time: 5-7 days

- Color: Grey, neutral finish

Automation CNC Machining FAQs

Standard lead time is 5–10 days, with options for expedited production if needed.

Yes, we handle metals, plastics, and composites suitable for demanding automation applications.

Absolutely, we accept STEP, IGES, STL, and most CAD formats for quoting and design evaluation.

Yes, we can provide Certificates of Conformance, material reports, and traceability upon request.

Provide 3D files, material specifications, surface finish requirements, tolerances, and expected quantity.

Start Your Automation CNC Machining Project Now!

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.