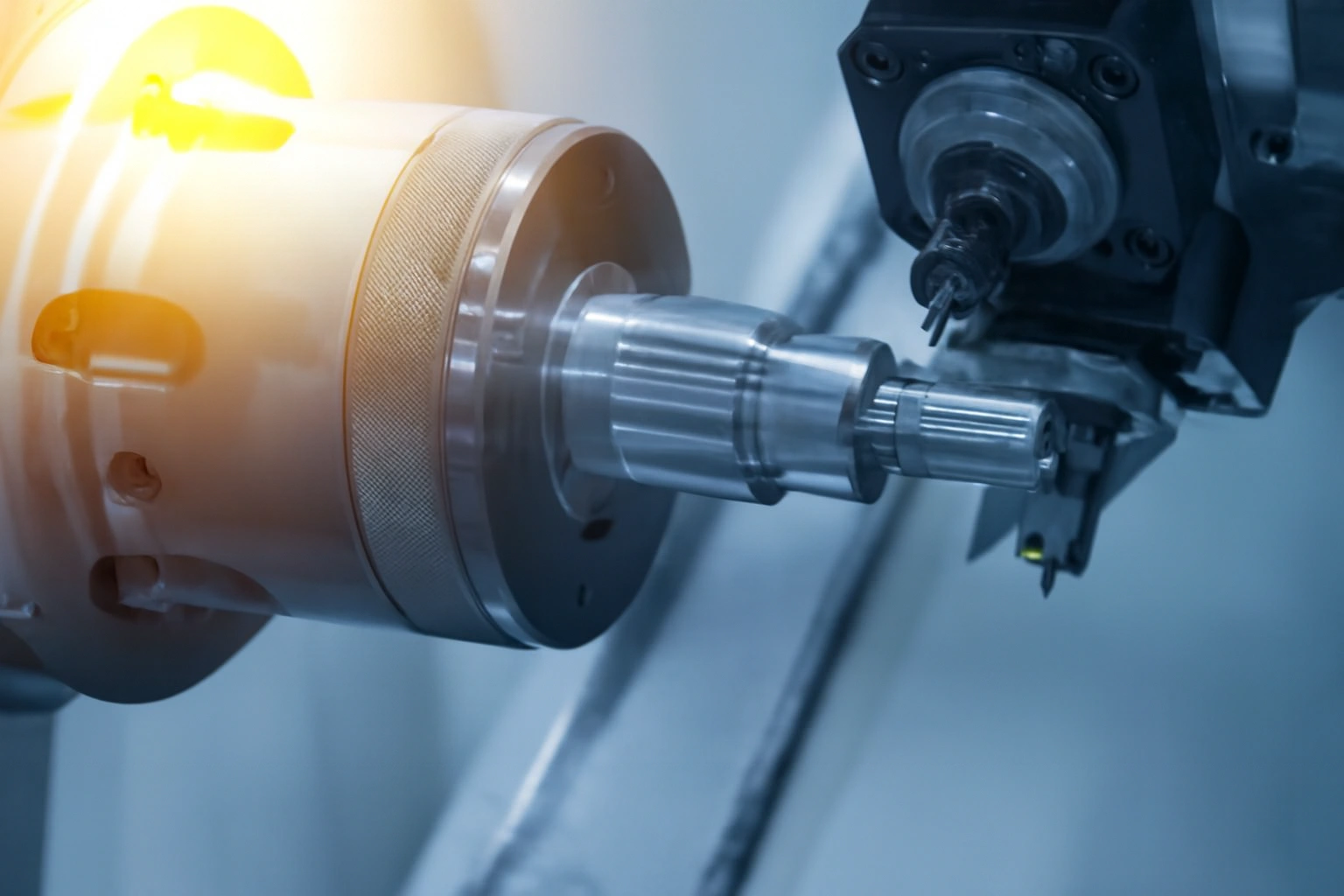

Custom CNC Turning Services

We provide comprehensive CNC turning services, delivering precision components from rapid prototypes to high-volume production runs, with tolerances up to ±0.01 mm and lead times as fast as 24 hours.

- Tolerances controlled within ±0.05mm

- Expedited CNC turning services available to meet tight deadlines with swift turnarounds.

- 100+ plastic and metal materials available

- Tailored CNC turned parts for both prototyping and large-scale manufacturing

Start a New CNC Turning Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable CNC Turning Services Provider from China

Robotika is a trusted CNC turning services manufacturer in China. Our facility is equipped with advanced CNC turning centers and multi-axis machines, enabling us to deliver rapid prototypes and high-volume production with tight tolerances up to ±0.01 mm. We go beyond machining by offering professional engineering support, including DFM (Design for Manufacturability) analysis, to help clients optimize designs, reduce production risks, and lower costs. Our quality control team inspects every part using advanced measuring equipment to ensure accuracy, surface finish, and dimensional consistency—making us a dependable partner for both functional end-use parts and aesthetic prototypes.

With over a decade of manufacturing experience, Robotika produces more than 100,000 precision-turned components annually, supplying industries such as automotive, aerospace, electronics, medical devices, and industrial machinery worldwide. We work with companies of all sizes, from startups to global manufacturers, delivering stable supply, competitive lead times, and outstanding service.

Our CNC Turning Services Capabilities

Robotika offers professional CNC turning services utilizing advanced CNC lathes and multi-axis turning centers, supported by automatic bar feeders and gantry loaders for efficient high-volume production. Our expertise in high-speed cutting with constant surface speed control ensures superior surface finishes and dimensional stability, while carbide and coated cutting tools allow us to process a wide range of materials, including aluminum, stainless steel, brass, copper, titanium, and engineering plastics such as POM, PEEK, and PTFE.To meet diverse industry requirements, we provide a variety of surface finishing options for CNC-turned parts, including anodizing, powder coating, sandblasting, polishing, electroplating, and passivation. Our operations achieve tolerances as tight as ±0.01 mm for metals and ±0.02 mm for plastics, verified by rigorous quality control processes using advanced CMMs and optical measuring systems.

CNC Turning Capabilities

Maximum Build Size

Typically, our measure up to 500 mm in diameter and 1500 mm in length, although larger sizes can be handled with specialized equipment.

Supported Materials

Our capable of machining aluminum, stainless steel, brass, copper, carbon steel, and engineering plastics (POM, ABS, Nylon, PEEK, etc.), meeting various industrial and custom production needs.

Machining Accuracy

Our standard tolerance controlled within ±0.01mm, ensuring high precision for mechanical components, electronic parts, and industrial applications.

Surface Finishing Options

We support anodizing, polishing, sandblasting, powder coating, electroplating, laser engraving, and more for enhanced durability and aesthetics.

Delivery Time

Our standard CNC machining lead time is 5-7 days, with expedited service available for urgent projects.

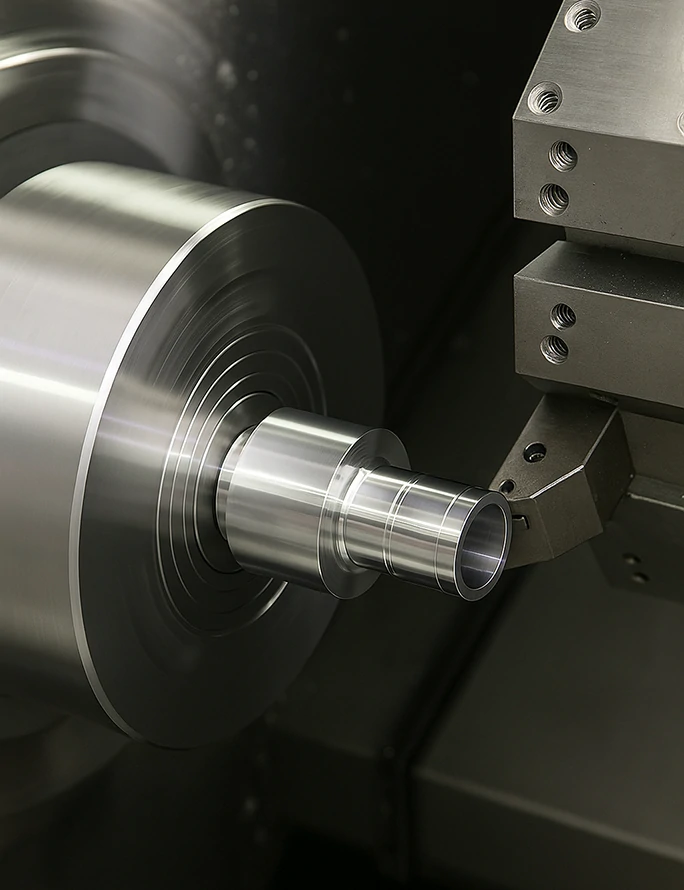

Our Latest CNC Turning Products We have Manufactured

Our precision-turned components are produced with excellent concentricity, smooth finishes, and consistent dimensional accuracy.

CNC Turning Tolerance

| Part Type | Tolerance Range |

|---|---|

| Aluminum | ±0.02 mm (±0.0008 in) |

| Stainless Steel | ±0.02 mm (±0.0008 in) |

| Brass / Copper | ±0.015 mm (±0.0006 in) |

| Titanium | ±0.025 mm (±0.001 in) |

| Engineering Plastics | ±0.05 mm (±0.002 in) |

| General Commercial Parts | ±0.05 mm (±0.002 in) |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

CNC Turning Materials

Aluminum alloys

Aluminum alloys are ideal for CNC turning due to their excellent machinability, high strength-to-weight ratio, and corrosion resistance. They enable fast, precise machining with tight tolerances and smooth finishes. In CNC turning, aluminum alloys are widely used for automotive components, aerospace fittings, electronic housings, and machinery parts—for example, engine brackets, aircraft connectors, and heat sink housings.

- Lead Time: As fast as 3 days.

- Finishes: Raw, anodized, bead blasted, polished.

Stainless steel

Stainless steel is well-suited for CNC turning due to its high strength, corrosion resistance, and ability to maintain dimensional stability under machining stress. It delivers excellent durability and wear resistance, making it ideal for precision parts in demanding environments. Typical applications include medical instrument shafts, automotive bushings, aerospace fasteners, and food-grade fittings where hygiene, strength, and longevity are critical.

- Lead Time: As fast as 3 days

- Finishes: Raw, polished, passivated, bead blasted

Carbon steel

Carbon steel is well-suited for CNC turning due to its high strength, toughness, and excellent machinability, making it ideal for durable, load-bearing components. In CNC turning, carbon steel is commonly used for shafts, gears, fasteners, and machine parts—for example, drive shafts, threaded rods, and couplings—where strength and wear resistance are critical.

- Lead Time: As fast as 3 days.

- Finishes: Raw, black oxide, zinc plated, polished.

Brass

Brass is an excellent choice for CNC turning due to its superior machinability, corrosion resistance, and attractive finish, allowing for precise and efficient production. In CNC turning, brass is widely used for fittings, valves, decorative hardware, and electronic components—for example, plumbing connectors, electrical terminals, and precision bushings—where accuracy and appearance are equally important.

- Lead Time: As fast as 3 days.

- Finishes: Raw, polished, nickel plated, chrome plated.

Copper

Copper is ideal for CNC turning due to its excellent thermal and electrical conductivity, corrosion resistance, and good machinability. In CNC turning, copper is widely used for electrical contacts, heat exchangers, plumbing parts, and industrial fittings—for example, bus bars, heat sink components, and threaded connectors—where conductivity and precision are critical.

- Lead Time: As fast as 3 days.

- Finishes: Raw, polished, nickel plated, tin plated.

Titanium Alloys

Titanium alloys are highly suitable for CNC turning due to their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. In CNC turning, they are widely used for aerospace components, medical implants, automotive performance parts, and marine hardware—for example, aircraft fasteners, bone screws, and racing engine valves—where strength and durability are essential.

- Lead Time: As fast as 5 days.

- Finishes: Raw, polished, bead blasted, anodized.

ABS

ABS (Acrylonitrile-Butadiene-Styrene) is ideal for CNC turning due to its toughness, impact resistance, and ease of machining at low temperatures. It allows for precise shaping and smooth finishes, making it suitable for automotive knobs, electronic housings, appliance handles, and prototype parts—for example, gear covers, switch housings, and instrument bezels.

- Mill Lead Time: Up to 3 days.

- Color: Black, neutral matte finish.

POM

POM (Polyoxymethylene) is ideal for CNC turning due to its low friction, high wear resistance, and excellent dimensional stability. It machines easily into precise components with smooth surfaces, making it suitable for gears, bushings, pulleys, and automotive fuel system parts—for example, precision rollers, valve seats, and fastening components.

- Mill Lead Time: Up to 3 days.

- Color: Black, white, natural finish.

Nylon

Nylon is ideal for CNC turning due to its high strength, wear resistance, and excellent impact absorption, while remaining lightweight and easy to machine. It is widely used for bushings, pulleys, gears, and sealing components—for example, bearing sleeves, timing pulleys, and valve seats—where durability and low friction are essential.

- Mill Lead Time: Up to 3 days.

- Color: Natural, black, white.

PVC

PVC (Polyvinyl Chloride) is ideal for CNC turning due to its excellent chemical resistance, low moisture absorption, and ease of machining. It is commonly used for pipe fittings, valve components, insulation parts, and chemical equipment—for example, threaded connectors, flange adapters, and protective covers—where durability and corrosion resistance are required.

- Mill Lead Time: Up to 3 days.

- Color: Gray, white, natural finish.

HDPE

HDPE (High-Density Polyethylene) is ideal for CNC turning due to its excellent impact resistance, low moisture absorption, and chemical durability. It machines smoothly into lightweight, tough parts, making it suitable for water system components, food processing equipment, and protective housings—for example, pipe fittings, cutting boards, and tank caps.

- Mill Lead Time: Up to 3 days.

- Color: Natural, black, white.

PEEK

PEEK (Polyether Ether Ketone) is ideal for CNC turning due to its exceptional strength, high-temperature resistance up to 260°C, and excellent chemical stability. It is widely used for aerospace components, medical implants, and semiconductor parts—for example, aircraft bushings, surgical instrument handles, and wafer processing fixtures—where precision and durability are critical.

- Mill Lead Time: Up to 3 days.

- Color: Black, neutral matte finish.

PTFE (Teflon)

PTFE (Polytetrafluoroethylene) is ideal for CNC turning due to its outstanding chemical resistance, extremely low friction, and excellent thermal stability. It is commonly used for seals, gaskets, insulators, and chemical handling parts—for example, valve seats, bearing pads, and electrical insulation components—where non-stick properties and durability are essential.

- Mill Lead Time: Up to 3 days.

- Color: White, matte finish.

PPS

PPS (Polyphenylene Sulfide) is ideal for CNC turning due to its excellent dimensional stability, high heat resistance, and strong chemical resistance. It is widely used for precision mechanical parts, electrical components, and automotive applications—for example, pump housings, connector insulators, and valve components—where stability under harsh conditions is required.

- Mill Lead Time: Up to 3 days.

- Color: Black, natural matte finish.

PVDF

PEEK (Polyether Ether Ketone) is ideal for CNC turning due to its exceptional strength, high heat resistance up to 260°C, and excellent chemical stability. It is widely used for aerospace parts, medical implants, and semiconductor components—for example, aircraft bushings, bone screws, and wafer handling fixtures—where precision and durability are critical.

- Mill Lead Time: Up to 3 days.

- Color: Black, neutral matte finish.

Ultem

Ultem (Polyetherimide, PEI) is ideal for CNC turning due to its high strength, heat resistance up to 170°C, and excellent electrical insulation properties. It is commonly used for aerospace components, medical devices, and electronic housings—for example, aircraft brackets, surgical instrument parts, and high-voltage insulators—where durability and dimensional stability are essential.

- Mill Lead Time: Up to 3 days.

- Color: Amber, natural matte finish.

Finishing Options for CNC Turning

| Name | Description | Colors | Can Be Applied with |

|---|---|---|---|

Anodizing (Type II & III)

Anodizing (Type II & III)

|

Electrochemical process that forms a protective oxide layer on aluminum. | Matte or glossy finish, colored or clear. | Aluminum alloys, aluminum CNC turned components |

Powder Coating

Powder Coating

|

Provides a durable, uniform coating that protects against wear, chemicals, and environmental factors. | Smooth or textured coating in various colors. | Aluminum, steel, stainless steel parts for machinery, consumer goods, automotive components. |

Electroplating (Nickel, Chrome, Zinc, Gold)

Electroplating (Nickel, Chrome, Zinc, Gold)

|

Deposits a thin metal layer onto the surface of a part using electrical current. | Bright, reflective metallic finish. | Steel shafts, brass fittings, decorative trim, electrical contacts. |

Polishing

Polishing

|

Mechanical or chemical process to smooth surfaces to a high gloss. | Glossy, mirror-like finish. | Stainless steel decorative parts, brass components, precision instruments. |

Bead Blasting / Sandblasting

Bead Blasting / Sandblasting

|

Uses abrasive media to create a uniform matte surface. | Matte, satin finish. | Aluminum enclosures, stainless steel covers, titanium parts. |

Passivation

Passivation

|

Chemical treatment that removes free iron from stainless steel surfaces. | Natural metallic finish. | Stainless steel CNC turned parts, medical devices, food processing equipment. |

Black Oxide

Black Oxide

|

Chemical conversion coating for steel and stainless steel. | Matte black finish. | Fasteners, tools, machine parts. |

Vapor Polishing

Vapor Polishing

|

Melts the outer surface of transparent plastics using vaporized solvents. | Clear, glossy transparent finish. | Polycarbonate lenses, acrylic display covers, optical components. |

Painting / Spray Coating

Painting / Spray Coating

|

Applies liquid paint for protection and color. | Glossy, matte, or textured finish. | Consumer products, automotive panels, machinery covers. |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

CNC Turning Design Guide

In this guide to CNC turning, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

CNC Turning Services FAQs

What’s your typical lead time for CNC turning parts?

Most orders ship within 3–7 days, and urgent jobs can be completed in as fast as 1 day.

Can you handle both prototypes and mass production?

Yes, we produce everything from single custom parts to large production runs.

What file formats do you accept for quotes?

We work with STEP, IGES, X_T, STL, and PDF drawings.

Do you work with both metals and plastics?

Absolutely — we machine aluminum, stainless steel, brass, copper, titanium, and engineering plastics like POM, PEEK, and PTFE.

What tolerances can you achieve for CNC turning?

We can achieve up to ±0.01 mm for metals and ±0.02 mm for plastics.

Can you arrange surface finishing?

Yes, we offer anodizing, powder coating, polishing, sandblasting, plating, and more.

Do you offer inspection reports?

Yes, we provide CMM and material inspection reports on request.

Are You CNC Turning Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.