CNC Manufacturing for Consumer Products

Robotika provides precision CNC manufacturing solutions for consumer products, with rapid prototype delivery in as fast as 7 days.

- 10+ years of CNC manufacturing experience in consumer products

- 3- to 5-axis CNC, high-speed EDM, and precision molding capabilities

- +0.01 mm tolerances on critical dimensions

- Wide selection of high-quality materials, including metals, plastics, and composites

- 24/7 engineering support, CMM inspection & full material traceability

Start Manufacturing Your CNC Consumer Products Parts!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable CNC Consumer Parts Supplier from China

Robotika specializes in CNC manufacturing for consumer products, offering rapid prototyping and flexible low- to medium-volume production that helps brands shorten development cycles and accelerate market launches. Our strength lies in producing both functional and cosmetic parts with excellent surface quality, tight fit, and reliable performance—ideal for consumer electronics, lifestyle products, and home appliances. With short lead times, DFM support, and the ability to combine metals with engineering plastics, we enable customers to validate designs quickly and move into production without delays.

Beyond machining, Robotika provides value-added services including material guidance, a wide range of custom surface finishes for consumer-grade appearance, and comprehensive inspection to ensure durability and consistency. With more than a decade of experience and over 100,000 parts delivered annually, we proudly serve global consumer brands, product design houses, and innovative startups across the electronics, lifestyle, and home product sectors.

What kind of consumer products parts can we make?

Robotika manufactures a wide range of CNC-machined components for consumer products, including electronic housings, smartphone and laptop frames, wearable casings, appliance knobs, handles, brackets, and decorative parts for lifestyle products. For these parts, we commonly use aluminum alloys for their lightweight strength and ability to achieve premium anodized finishes, stainless steel for durability and scratch resistance, brass and copper for decorative appeal, and plastics such as ABS, PC, PMMA, and POM for their excellent surface quality, transparency, or smooth tactile feel. To meet both functional and aesthetic requirements, we provide finishes like anodizing, brushing, bead blasting, polishing, painting, and powder coating to create high-end consumer-grade appearances.

- Smartphone frames

- Laptop housings

- Tablet enclosures

- Wearable device casings (smartwatches, fitness trackers)

- Headphone and earbud housings

- Gaming console parts

- Camera housings and lens mounts

- Smart home device enclosures

- Remote control shells

- Appliance knobs and dials

- Handles and decorative trims

- Kitchen appliance housings (blenders, coffee machines)

- Small household device brackets

- Power tool housings and grips

- Bicycle components

- Sports equipment parts

- Fashion accessories

- Lighting fixture housings

- Audio system components

- Personal care device parts

- Cosmetic packaging components

- Wear-resistant buttons and fasteners

- Decorative metal or plastic covers

Consumer Products CNC Machining Capabilities

Supported Materials

We specialize in machining consumer products-grade materials such as aluminum alloys (6061, 7075), titanium (Ti-6Al-4V), stainless steel (304, 316L), and engineering plastics like PEEK and PTFE, ideal for high-precision consumer components.

Machining Accuracy

Our standard tolerances of ±0.01mm ensure precise fit and consistent quality for housings, enclosures, and functional parts.

Maximum Machining Size

Up to 1000mm × 600mm × 500mm, accommodating a wide range of consumer products.

Surface Finishing Options

We provide anodizing, polishing, bead blasting, and powder coating enhance appearance and durability.

Delivery Time

Our typical lead time 5–10 days, with rush options available for urgent projects.

CNC Manufacturing for Consumer Products Workflow

Our market-ready CNC manufacturing workflow ensures dimensional accuracy, consistent appearance, and reliable quality from engineering review to production-ready delivery.

Engineering Review & DFM

We review drawings and 3D models to evaluate tolerances, materials, surface requirements, and manufacturability, ensuring designs are suitable for consumer product production.

Precision CNC Machining

Using multi-axis CNC machines, we manufacture consumer components from plastics, metals, and engineering materials consistently.

Prototype & Validation

Prototype or first article parts are produced for dimensional verification, assembly fitting, and appearance validation before moving to volume production.

Inspection & Quality Control

All parts undergo in-process and final inspections, including dimensional, visual, and surface checks, to ensure consistency and market-ready quality.

Packaging & Delivery

Components are cleaned, protected, and securely packaged to prevent damage during handling and transportation, supporting safe delivery to market.

Services that Meet Your Consumer Products CNC Manufacturing Needs

Our CNC manufacturing services support consumer products with consistent quality, attractive appearance, and reliable production from engineering review to market-ready delivery.

Drawing Review

We review drawings and 3D models to understand geometry, tolerances, appearance requirements, and functional expectations for consumer product components.

Material Evaluation

We confirm material selections to balance strength, appearance, cost efficiency, and suitability for consumer product manufacturing and end use.

Tolerance Evaluation

We analyze critical tolerances and fit requirements to ensure smooth assembly and consistent product performance across production batches.

Manufacturability Review

We identify machining challenges and optimize designs to improve manufacturability, reduce cost, and support scalable consumer product production.

Machining Strategy

We define machining strategies and setups based on part geometry, materials, and appearance requirements for consumer product components.

Tooling & Fixtures

We select appropriate tools and fixtures to ensure precision, surface quality, and repeatable results during CNC machining.

Quality Planning

We establish inspection standards and checkpoints to maintain consistent quality and appearance throughout the production process.

Production Scheduling

We plan capacity and lead times to support fast market response and reliable delivery for consumer product programs.

Prototype Machining

We produce prototype or first article parts to validate geometry, tolerances, and surface quality before volume production.

Assembly Verification

We verify part fit and assembly compatibility to ensure smooth integration into consumer product assemblies.

Appearance Evaluation

We review surface finish and visual details to meet consumer market expectations and brand requirements.

Design Optimization

We provide feedback to refine designs and prepare products for efficient and stable mass production.

Multi-Axis CNC Machining

We machine consumer product components using advanced CNC equipment to achieve consistent accuracy and surface quality.

Material Processing

We process plastics, aluminum, stainless steel, and engineering materials commonly used in consumer product manufacturing.

In-Process Inspection

We perform inspections during machining to maintain dimensional consistency and appearance standards.

Batch Production Control

We ensure repeatable processes and stable quality across small to medium consumer product production runs.

Dimensional Inspection

We conduct final dimensional inspections to verify accuracy and compliance with design specifications.

Visual Inspection

We inspect surface finish and cosmetic details to meet consumer product quality expectations.

Quality Records

We document inspection results to ensure consistency and quality control across production batches.

Final Approval

We approve parts for delivery only after all quality and appearance requirements are fully met.

Part Cleaning

We clean finished components to remove residues and prepare parts for safe packaging.

Protective Packaging

We apply protective packaging to prevent scratches or damage during handling and transportation.

Secure Packing

We pack products securely to ensure safe transit and maintain appearance quality.

On-Time Delivery

We arrange reliable logistics to ensure consumer product components arrive on time for market launch.

Total Consumer Products Project Success with 360° Robotika Approach

Precision That Supports Great Design

We deliver accurate dimensions and tight tolerances to ensure consumer product components assemble smoothly and perform consistently across production batches.

Appearance and Material Control

We machine plastics, aluminum, stainless steel, and engineering materials with controlled surface quality to meet consumer market expectations and brand standards.

Engineering-Focused Manufacturing

Our engineering team supports DFM review and process optimization to improve manufacturability, control costs, and accelerate consumer product development cycles.

Reliable Production and Delivery

From prototypes to repeat orders, our controlled processes ensure stable quality, predictable lead times, and on-time delivery for consumer product launches.

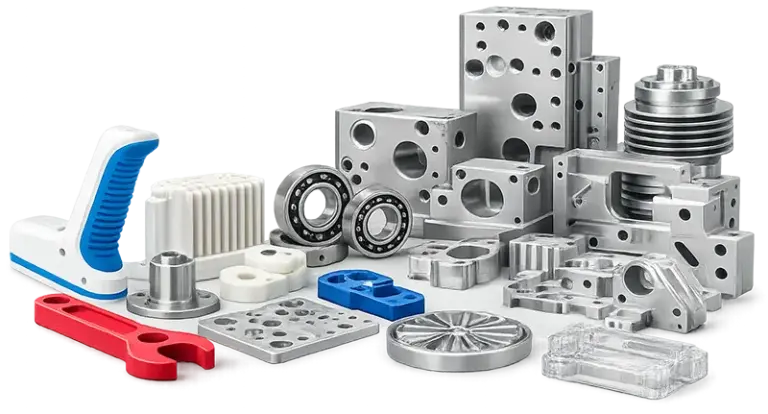

Consumer Products We Have Manufactured

Explore a selection of consumer products we have manufactured, showcasing our capabilities in precision machining, material control, and quality assurance.

Consumer Products CNC Machining FAQs

The typical lead time for consumer products CNC machining parts is usually 2-4 weeks, depending on complexity and order volume.

Yes, we handle metals, advanced plastics, and composites commonly used in EVs, battery systems, and renewable energy equipment.

Absolutely. Share your STEP, IGES, or STL file along with material, quantity, and surface finish requirements, and we’ll provide a detailed quote.

Yes. We can supply material certification and traceability reports to ensure quality and compliance for your components.

Provide your 3D file, material choice, tolerances, surface finish, quantity, and any special requirements for assembly or performance.

Start Your Consumer Products CNC Machining Project Now!

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.