CNC Manufacturing for Electronics

Robotika provides precision CNC machining services tailored to the electronics industry’s high standards, with rapid prototype delivery in as fast as 7 days.

- 10 years of CNC manufacturing experience in electronics

- 3- to 5-axis CNC, high-speed EDM, and precision molding capabilities

- +0.01 mm tolerances on critical dimensions

- 24/7 engineering support, CMM inspection & full material traceability

Start Manufacturing Your Electronics Parts!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable Eletronics Parts CNC Machining Supplier from China

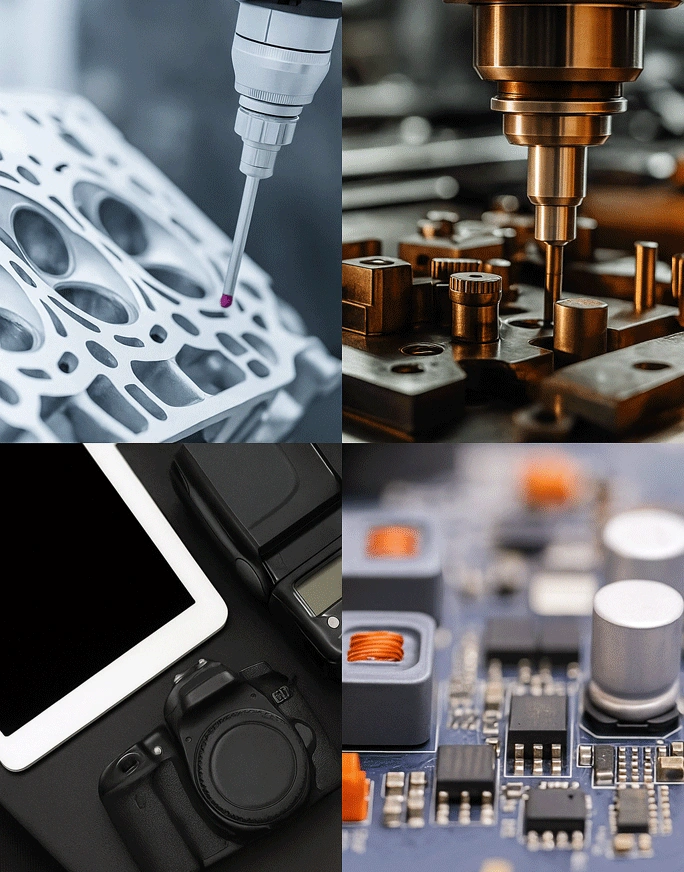

Robotika provides CNC manufacturing services for the electronics industry, offering high-precision prototyping and low- to medium-volume production of critical components. With advanced 3-, 4-, and 5-axis machining centers. Our strength lies in rapid prototyping (as fast as 7 days), the flexibility to combine metals and engineering plastics, and the ability to support both functional testing parts and customer-facing cosmetic housings, helping electronics manufacturers accelerate development while ensuring reliable performance and refined product aesthetics.

In addition, Robotika provides value-added services including material consultation for lightweight alloys and high-performance polymers, finishing options tailored for durability and appearance, and comprehensive quality inspection using automated CMM systems. With over 10 years of experience and more than 100,000 parts delivered annually, we proudly serve consumer electronics brands, computing device makers, telecommunications equipment providers, and technology startups worldwide, delivering dependable CNC solutions from prototype to production.

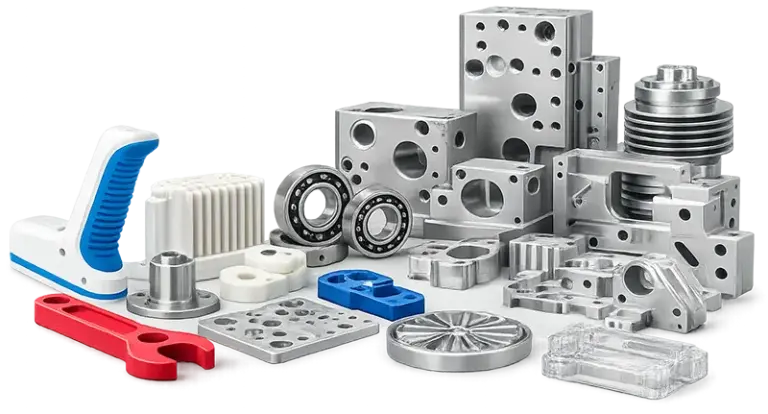

What kind of electronics parts can we make?

Robotika manufactures a variety of high-precision components for the electronics industry, including device housings, heat sinks, mounting brackets, connector shells, shielding covers, and structural frames used in consumer electronics, computing devices, and communication equipment. These parts are typically produced from aluminum alloys, stainless steel, copper, and engineering plastics such as ABS, PC, and PEEK for insulation, flame retardancy, and lightweight design. To meet both performance and aesthetic requirements, we provide finishing options such as anodizing for a premium appearance, bead blasting for uniform textures, powder coating for protection, and electropolishing for smooth surfaces. All parts tolerances up to ±0.01 mm.

- Housings

- Brackets

- Connectors

- Fasteners

- Gear Casings

- Valve Components

- Coupling Fittings

- Sensor Enclosures

- Pump Housings

- Electrical Enclosures

- Cable Clips

- Manifolds

- Heat Sinks

- Motor Mounts

- Seals & Gaskets

- Switch Housings

- Instrument Panels

- Bolts & Nuts

- Nozzles

- Bearing Housings

- Fluid Control Valves

- Cam Housings

- Pipe Adapters

- Piping Fittings

Electronics CNC Machining Capabilities

Supported Materials

We specialize in machining electronics-grade materials such as aluminum alloys (6061, 7075), stainless steel (304, 316L), titanium (Ti-6Al-4V), and advanced plastics like PEEK and PTFE, suitable for high-performance electronics applications.

Machining Accuracy

We maintain standard tolerance within ±0.01mm, ensuring high precision for electronics components.

Maximum Machining Size

Our maximum machining size is 1000mm × 600mm × 500mm, accommodating various electronics parts.

Surface Finishing Options

We offer anodizing, polishing, bead blasting, and powder coating to enhance durability.

Delivery Time

Standard lead time is 7-10 days, with expedited services available for urgent projects.

CNC Manufacturing for Electronics Workflow

Our controlled CNC manufacturing workflow designed for electronic components, ensuring dimensional accuracy, and material consistency from engineering review to production-ready delivery.

Engineering Review & DFM

We review drawings and 3D models to evaluate tolerances, materials, critical features, and manufacturability, ensuring suitability for electronic applications and reducing production risks.

Precision CNC Machining

Using multi-axis CNC machines, we manufacture electronic components with tight tolerances and consistent quality.

Prototype & First Article

Prototype or first article parts are produced for dimensional verification and functional evaluation, confirming machining accuracy and fit before moving to volume production.

Inspection & Quality Control

All parts undergo in-process and final inspections, including dimensional checks and visual verification, to ensure consistency, reliability, and compliance with electronic industry requirements.

Packaging & Delivery

Components are cleaned, protected, and securely packaged to prevent damage or contamination, ensuring safe delivery of production-ready electronic parts.

Services that Meet Your Electronics CNC Manufacturing Needs

Our structured electronics CNC manufacturing process delivers tight tolerances and reliable quality from engineering review to production-ready delivery.

Drawing Review

We analyze 2D drawings and 3D models to understand geometry, tolerances, critical features, and functional requirements for electronic components.

Material Verification

We confirm specified materials, grades, and properties to ensure suitability for electronic applications and performance expectations.

Tolerance Evaluation

We assess tight tolerances and key dimensions to determine machining feasibility and potential risk areas.

Manufacturability Assessment

We identify machining challenges and optimize designs for stable, repeatable production.

Machining Strategy

We define machining methods, setups, and sequences based on part structure and electronic application requirements.

Tooling Selection

We select appropriate tools and fixtures to ensure precision, stability, and surface quality during machining.

Quality Control Plan

We establish inspection points and measurement methods to control quality throughout the process.

Production Scheduling

We plan capacity and lead times to support fast development cycles and on-time delivery.

Prototype Machining

We produce prototype parts to validate geometry, tolerances, and overall manufacturability.

Fit & Function Check

We verify part fit, assembly compatibility, and functional requirements for electronic use.

Design Feedback

We provide feedback and recommendations to optimize designs before volume production.

Approval for Production

We confirm all technical details before moving forward with CNC production.

Multi-Axis CNC Machining

We machine electronic components using advanced CNC equipment for complex geometries and tight tolerances.

Material Processing

We process aluminum, copper, stainless steel, plastics, and engineering materials with precision control.

In-Process Inspection

We perform inspections during machining to maintain consistency and dimensional accuracy.

Batch Production Control

We ensure stable quality and repeatability across small- to medium-volume production runs.

Dimensional Inspection

We conduct final dimensional checks using calibrated measuring equipment.

Visual Inspection

We inspect surface finish, edges, and critical features to meet electronic industry standards.

Quality Records

We document inspection results to ensure traceability and quality consistency.

Final Approval

We approve parts for delivery only after all quality requirements are met.

Part Cleaning

We clean finished components to remove residues and contaminants.

Protective Packaging

We apply protective packaging to prevent damage or contamination during transit.

Secure Packing

We pack parts securely based on size, quantity, and shipping method.

Global Delivery

We arrange reliable logistics to ensure safe and timely delivery of production-ready electronic parts.

Total Electronics Project Success with 360° Robotika Approach

Precision You Can Rely On

We deliver tight tolerances and consistent accuracy through advanced CNC machining, ensuring electronic components fit, assemble, and perform reliably across prototypes and production runs.

Certified Materials & Traceability

We machine aluminum, copper, stainless steel, plastics, and engineering materials commonly used in electronics, ensuring material suitability, surface quality, and performance consistency.

Engineering-Driven Manufacturing

Our engineering team supports DFM review, process planning, and rapid problem-solving to reduce iterations, shorten lead times, and improve manufacturability for electronic designs.

Quality-Controlled Delivery

From prototype validation to final inspection and secure packaging, every step is controlled to ensure stable quality and on-time delivery of production-ready electronic components.

Electronics Parts We Have Manufactured

Explore a selection of electronics components we have manufactured, showcasing our capabilities in precision machining, material control, and quality assurance.

Electronics CNC Machining FAQs

For prototypes and small production runs take around 7-10 days. For larger or more complex orders, it can take 2-3 weeks.

Yes, we specialize in machining high-performance materials such as aluminum alloys (6061, 7075), titanium (Ti-6Al-4V), and engineering plastics like PEEK and PTFE, which are ideal for electronics applications.

Yes, you can send us your 3D CAD file (STEP, IGES, or STL format), and we’ll provide a custom quote based on your material, quantity, and specific requirements.

Yes, we offer Certificates of Conformance (CoC) and full material traceability to meet your quality control needs and industry standards.

To begin, simply provide your 3D CAD file, material specifications, desired quantity, surface finish preferences, and delivery deadlines, and we’ll provide a detailed quote and timeline.

Start Your Electronics CNC Machining Project Now!

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.