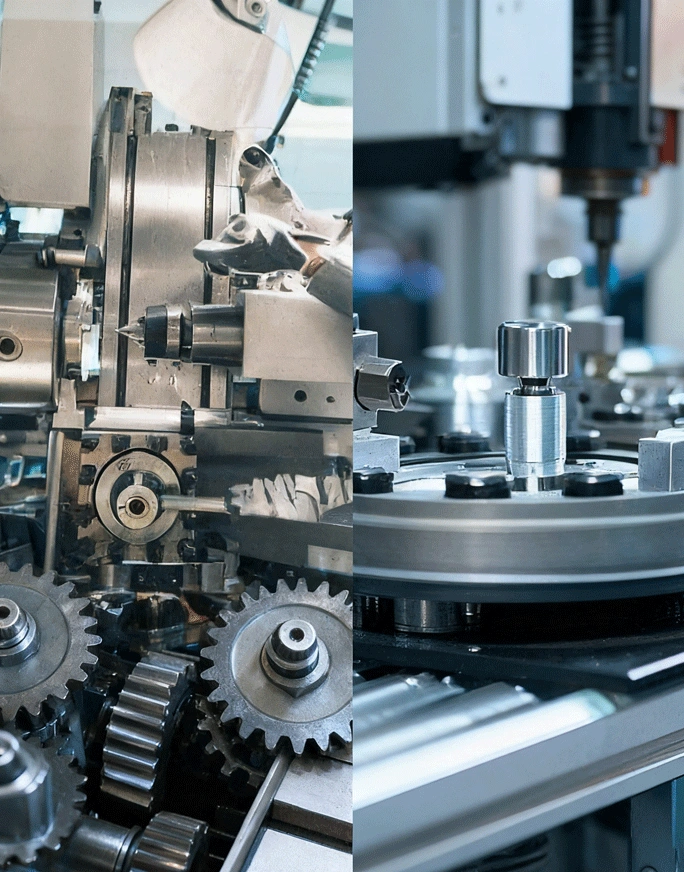

CNC Manufacturing for Industrial Equipment

Robotika provides precision CNC machining services tailored to the industrial equipment, with fast turnaround times in as fast as 7 days.

- 10+ years of industrial CNC manufacturing experience

- Achieve ±0.01 mm tolerances on every critical dimension

- Optional materials such as aviation grade aluminum and titanium

- 24/7 engineering support, CMM inspection & full material traceability

Start Manufacturing Your Industrial Parts !

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable CNC Industrial Parts Supplier from China

Robotika provides CNC manufacturing services for the industrial equipment, specializing in high-precision prototyping and low- to medium-volume production. Equipped with advanced 3-, 4-, and 5-axis machining centers, high-speed EDM, and turning-milling equipment, we are capable of producing large, complex, and heavy-duty components with excellent accuracy and durability. Our advantage lies in combining reliable machining capacity with fast turnaround times, DFM support, and the flexibility to process both high-strength metals and engineering plastics, helping industrial equipment manufacturers reduce lead times and ensure long-term performance.

In addition, Robotika offers custom finishing options such as anodizing, passivation, powder coating, and electropolishing, and comprehensive inspection using automated CMM systems. With over 10 years of experience and more than 100,000 parts delivered annually, we proudly serve machinery manufacturers, automation solution providers, heavy equipment suppliers, and engineering firms worldwide, delivering dependable CNC solutions from prototype through production.

What kind of industrial equipment parts can we make?

Robotika manufactures a wide range of CNC-machined components for the industrial equipment, including gear housings, bearing blocks, shafts, brackets, machine frames, heat sinks, and hydraulic manifolds. These parts are commonly produced from high-strength materials such as alloy steel for wear and load-bearing performance, stainless steel for durability and corrosion resistance, aluminum alloys for lightweight yet rigid structures, copper for heat dissipation, and engineering plastics like PEEK, nylon, and Delrin for insulating or low-friction applications. To ensure reliability in demanding environments, we provide finishing options. All components are verified using automated CMM inspection and visual checks, achieving tight tolerances up to ±0.01 mm, ensuring long-term precision and consistent quality in industrial assemblies.

- Gear housings

- Bearing blocks

- Shafts

- Couplings

- Pulleys

- Machine frames

- Mounting brackets

- Hydraulic manifolds

- Pump housings

- Valve bodies

- Flanges

- Heat sinks

- Cooling plates

- Guide rails

- Linear motion components

- Structural supports

- Clamping fixtures

- Gearbox covers

- Motor bases

- Spacer rings

- Sensor housings

- Control panel enclosures

- Fastening plates

- Roller supports

Industrial Equipment CNC Machining Capabilities

Supported Materials

We specialize in machining industrial-grade materials such as aluminum alloys (6061, 7075), stainless steel (304, 316L), titanium (Ti-6Al-4V), and advanced plastics like PEEK and PPSU, ideal for Industrial Equipment applications.

Machining Accuracy

Our machining accuracy is maintained within ±0.01mm, ensuring precision for complex industrial components.

Maximum Machining Size

We can machine parts up to 1000mm × 600mm × 500mm.

Surface Finishing Options

We offer anodizing, powder coating, bead blasting, and polishing to enhance part performance.

Delivery Time

Typical CNC machining lead time is 7-10 days, with expedited options available.

Experience the boundless possibilities of customization

Enhance your industrial equipment components with advanced surface finishes and precision detailing. At Robotika, we customize each part to meet your exact specifications—including material selection, geometry, and coating—ensuring durability, performance, and full compliance with industrial standards.

| Name | Tolerance Range |

|---|---|

| Standard Industrial Parts | ±0.2 mm to ±0.5 mm |

| Precision Industrial Parts | ±0.05 mm to ±0.2 mm |

| Complex Industrial Parts | ±0.1 mm to ±0.3 mm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

| Name | Description | Can Be Applied with | |

|---|---|---|---|

|

Anodizing | Improves corrosion resistance and surface hardness, commonly used for aluminum alloys and other metals. | Industrial machinery parts, mechanical components, hydraulic systems |

|

Powder Coating | Provides a durable, corrosion-resistant surface, suitable for most metals and plastic parts. | Industrial equipment frames, conveyor systems, structural components |

|

Polishing | Increases gloss and enhances appearance, commonly used for stainless steel, aluminum, and other materials. | Industrial parts, automotive components, mechanical equipment |

|

Bead Blasting | Provides a uniform surface texture, improving durability and wear resistance, suitable for metal and plastic parts. | Industrial equipment housings, heavy machinery parts, metal enclosures |

|

Passivation | Enhances corrosion resistance of stainless steel parts through chemical treatment, commonly used for industrial equipment requiring long-term corrosion resistance. | Stainless steel components in industrial systems, valves, pumps |

|

Nickel Plating | Provides good corrosion resistance and hardness, commonly used to enhance the durability of metal parts. | Industrial equipment components, valve seats, gears, automotive systems |

|

Electropolishing | Removes surface imperfections, improving surface smoothness, commonly used for stainless steel parts to enhance corrosion resistance. | Industrial machinery parts, stainless steel equipment, pumps and valves |

|

Chromate Conversion Coating | Provides additional protection for materials like aluminum alloys, suitable for industrial applications requiring high corrosion resistance. | Aluminum industrial parts, outdoor equipment, machinery components |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Aluminum Alloys (6061, 7075)

Aluminum alloys (6061, 7075) are ideal for CNC machining in industrial equipment, thanks to their excellent machinability that allows for precise cutting of complex geometries, lightweight properties that reduce equipment load without compromising structural integrity, and strong corrosion resistance to withstand moisture, oils, and mild chemicals. These alloys excel in applications demanding both strength and durability: 6061, with its balanced tensile strength and ductility, is widely used for machine frames, structural supports, and brackets, while 7075, a high-strength variant, handles high-stress roles like gears and transmission components in heavy machinery, ensuring reliable performance under continuous strain.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, anodized, bead blasted, polished

Stainless Steel (304, 316L, and 17-4PH)

Stainless steel grades such as 304, 316L, and 17-4PH are indispensable for CNC machining in industrial equipment, offering a robust combination of high tensile strength (up to 600 MPa for 17-4PH), exceptional corrosion resistance, and long-term durability—critical for parts exposed to harsh environments. 304, a chromium-nickel alloy, provides general resistance to rust and mild chemicals, making it perfect for valves, fasteners, and pumps in standard industrial settings like factories and water treatment plants. 316L, enhanced with molybdenum, boasts superior resistance to saltwater and aggressive chemicals, making it ideal for marine equipment, chemical processing machinery, and coastal industrial facilities, ensuring components remain intact even after years of exposure to corrosive substances.

- Mill Lead Time: As fast as 4 days

- Finishes: Raw, passivated, polished, bead blasted

Carbon Steel

Carbon steel grades like A36 and 1018 are workhorses in CNC machining for industrial equipment, valued for their impressive strength, versatility, and cost-effectiveness. A36, a low-carbon steel with a yield strength of 250 MPa, is a staple for structural supports, heavy-duty machinery frames, and load-bearing components in construction equipment and manufacturing lines, where its ability to withstand heavy static loads is crucial. 1018, a higher-machinability variant with better ductility, is ideal for parts needing precise shaping—such as shafts, brackets, and fasteners—balancing moderate strength (tensile strength around 400 MPa) with ease of cutting, drilling, and welding, making it a go-to for general-purpose industrial components.

- Mill Lead Time: As fast as 5 days

- Finishes: Raw, painted, powder coated

Titanium Alloys

Titanium alloys like Ti-6Al-4V are prized for CNC machining in industrial applications, boasting an exceptional strength-to-weight ratio that rivals high-strength steel but with 40% less weight, making them ideal for reducing inertia in moving parts. Their superior corrosion resistance is another key trait—they resist attack from saltwater, acids, and even bodily fluids, ensuring longevity in marine, chemical processing, and medical equipment. With a tensile strength of 900-1100 MPa, Ti-6Al-4V handles extreme temperatures (up to 400°C) without degrading, making it indispensable for aerospace components, high-performance valves, and precision pumps in corrosive environments where durability and lightweight properties are critical for safety and efficiency.

- Mill Lead Time: As fast as 5 days

- Finishes: Raw, anodized, polished

Copper Alloys

Copper alloys such as C110 and C360 are essential for CNC machining industrial parts requiring top-tier electrical and thermal conductivity. C110, a high-purity oxygen-free copper with 99.9% copper content, offers electrical conductivity exceeding 98% of the International Annealed Copper Standard (IACS), making it perfect for high-conductivity components like busbars, electrical connectors, and heat sinks in power distribution systems. C360, a brass-copper blend with 60% copper and 40% zinc, balances strong conductivity (65% IACS) with excellent machinability, allowing for intricate shapes like threaded fittings, valves, and heat exchanger tubes, where efficient energy transfer and ease of manufacturing are equally important.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, plated, polished

Brass

Brass, particularly C360, is a go-to material for CNC machining in industrial equipment, thanks to its excellent machinability—rated 100 on the machinability index, making it easier to cut than steel—allowing for intricate, tight-tolerance parts with smooth surfaces. It also offers solid corrosion resistance, especially in moist environments, and a moderate tensile strength of 300-400 MPa, suitable for load-bearing components. Its low friction coefficient (0.03-0.05) reduces wear in moving parts, making it ideal for fittings, gears, and valves in hydraulic and pneumatic systems. C360’s ability to hold dimensions within ±0.01 mm ensures reliable performance in precision components like connectors and small gears, even after repeated use.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, polished, nickel-plated

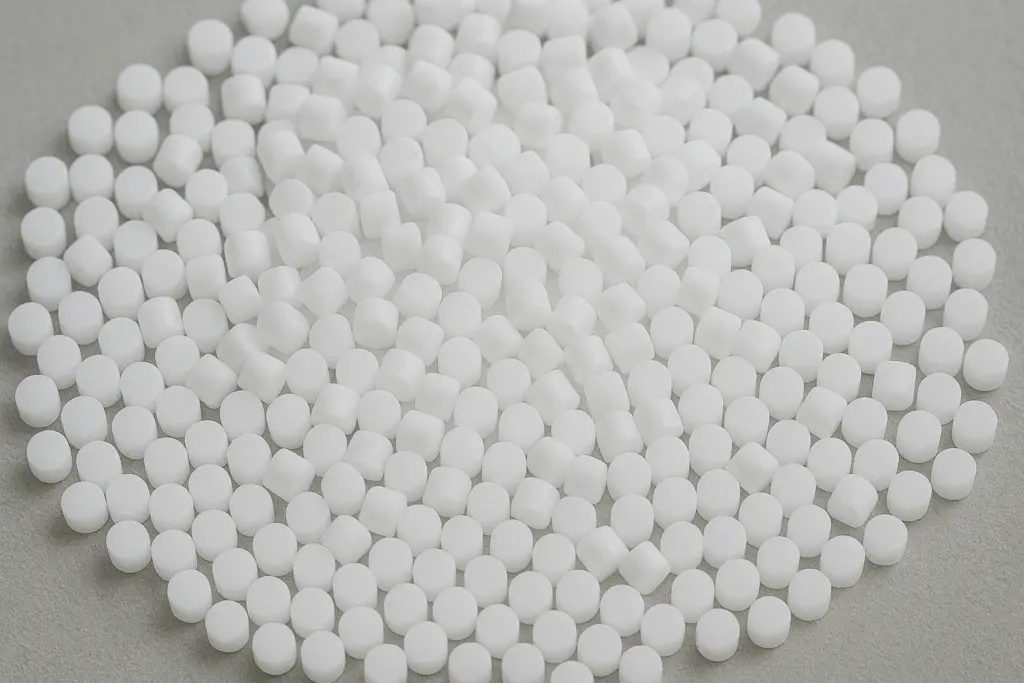

PEEK

PEEK is a high-performance plastic that excels in CNC machining industrial parts, featuring exceptional mechanical strength (tensile strength of 90 MPa) to withstand heavy loads, high-temperature resistance (continuous use up to 260°C, short-term up to 300°C), and chemical stability against oils, solvents, and strong acids like sulfuric acid. These properties make it perfect for seals, bearings, and gears in industrial pumps and valves, where it resists creep and wear under extreme stress. Unlike many plastics, PEEK retains its strength in hot, chemical-rich environments—such as oil refineries or pharmaceutical manufacturing—ensuring long-term reliability in applications where failure could lead to costly downtime.

- Mill Lead Time: Up to 5 days

- Color: Natural, black matte finish

PTFE

PTFE is a unique material for CNC machining industrial parts, renowned for its near-universal chemical resistance—it remains inert to 99% of known chemicals, including hydrofluoric acid and chlorine—and an ultra-low friction coefficient (0.04), second only to some solid lubricants. These traits make it indispensable for seals, gaskets, and bearings in pumps, valves, and chemical processing equipment, where it prevents leaks and reduces friction-induced wear. PTFE also operates across a wide temperature range (-200°C to 260°C), making it suitable for cryogenic and high-heat industrial settings, ensuring consistent performance in extreme conditions.

- Mill Lead Time: Up to 5 days

- Color: Natural, white finish

Nylon

Nylon is a durable, impact-resistant material perfect for CNC machining industrial equipment parts, offering excellent wear resistance (abrasion resistance comparable to some metals), high tensile strength (60-90 MPa), and a low coefficient of friction (0.1-0.2). Its ability to absorb shocks—up to 20 kJ/m² impact strength—makes it ideal for bearings, gears, and bushings in conveyor systems and heavy machinery, where it reduces noise and vibration. Nylon also resists oils and many chemicals, ensuring longevity in factory environments, and its self-lubricating properties eliminate the need for frequent maintenance, making it a cost-effective choice for high-use components.

- Mill Lead Time: As fast as 4 days

- Color: Natural, black finish

PPSU

PPSU is a high-performance plastic ideal for CNC machining in industrial applications, boasting high tensile strength (80 MPa), resistance to temperatures up to 180°C (with short-term tolerance of 200°C), and stability against harsh chemicals like detergents, hydrocarbons, and even some acids. These properties make it suitable for aerospace components, medical device housings, and fluid handling parts such as pumps and valves in food processing and pharmaceutical industries. PPSU also withstands repeated steam sterilization (autoclaving) without degrading, making it a reliable choice for equipment requiring strict hygiene standards, outperforming many plastics in demanding industrial environments.

- Mill Lead Time: Up to 5 days

- Color: Natural, black matte finish

ABS

ABS is an excellent choice for CNC machining, offering strong mechanical properties (tensile strength 40-50 MPa), high impact resistance (20-30 kJ/m², even at low temperatures), and a low processing temperature (180-240°C) that simplifies cutting complex shapes with tight tolerances (±0.02 mm). Its smooth surface finish and ability to bond with adhesives or paints make it ideal for industrial enclosures, housings for control panels, and protective covers, where both structural strength and a professional appearance are essential. ABS also resists oils and greases, ensuring durability in factory settings, and its affordability makes it a popular choice for mass-produced components.

- Mill Lead Time: As fast as 3 days

- Color: Black, neutral matte finish

Polycarbonate

Polycarbonate is renowned for its exceptional toughness—impact strength of 60-80 kJ/m², making it 250 times stronger than glass—and high transparency (light transmission of 85-90%), making it ideal for CNC machining industrial parts requiring both durability and visibility. It’s widely used for machine covers, protective shields in manufacturing lines, and safety enclosures around robotic arms, where it protects workers from flying debris while allowing clear monitoring of processes. Polycarbonate also resists UV radiation and temperatures up to 120°C, ensuring long-term clarity and strength in outdoor or heated industrial environments, outperforming acrylic in impact resistance.

- Mill Lead Time: As fast as 4 days

- Color: Clear, translucent finish

Carbon Fiber Reinforced Plastics

Carbon fiber composites are highly suitable for CNC machining in industrial equipment, combining extreme lightweight properties (density 1.5-1.8 g/cm³, lighter than aluminum) with exceptional strength (tensile strength 2000-3000 MPa) and stiffness (Young’s modulus 150-200 GPa), rivaling high-strength steel. These materials excel in high-performance applications like automotive chassis, aerospace structural components, and robotic arms, where reducing weight while maintaining rigidity enhances speed, precision, and energy efficiency. Their low thermal expansion coefficient (2-4 ppm/°C) also ensures dimensional stability in temperature-fluctuating environments, making them ideal for precision machinery.

- Mill Lead Time: Up to 7 days

- Color: Black, matte finish

Glass Fiber Reinforced Plastics

GGlass fiber reinforced plastics offer excellent strength (tensile strength 100-300 MPa), durability, and impact resistance at a more affordable cost than carbon fiber—typically 30-50% cheaper—making them ideal for industrial applications. They’re widely used for structural parts like equipment frames, housings for heavy machinery, and electrical enclosures, where they resist corrosion, moisture, and UV damage better than steel. With a density of 1.8-2.2 g/cm³ (lighter than steel but heavier than carbon fiber), they balance weight and strength, suiting applications like conveyor system components and protective covers, providing reliable performance without the premium price tag.

- Mill Lead Time: Up to 6 days

- Color: Black, gray finish

Metal Matrix Composites

Metal matrix composites (MMCs) combine the high strength and thermal conductivity of metals (like aluminum or titanium) with the lightweight, low-density properties of reinforcements (such as carbon fibers or ceramic particles). This blend creates materials with tensile strengths up to 1000 MPa and a density 10-30% lower than pure metals, making them ideal for CNC machining high-performance industrial parts. They’re used in gears, pistons, and turbine components in racing engines and heavy machinery, where high strength, wear resistance, and reduced weight enhance fuel efficiency and performance. MMCs also withstand extreme temperatures (up to 500°C) and resist creep, ensuring longevity under continuous stress.

- Mill Lead Time: Up to 7 days

- Color: Natural, matte finish

Industrial Equipment CNC Machining FAQs

For prototypes and small production runs, it’s around 7-10 days. Larger orders may take up to 2-3 weeks, depending on the complexity and quantity of parts.

Yes, we specialize in machining a variety of industrial-grade materials, including carbon steel, titanium alloys (e.g. Ti-6Al-4V), PEEK, stainless steel, and aluminum alloys, suitable for high-performance industrial applications.

Yes, just send us your 3D CAD file (STEP or IGES format), and we’ll provide a custom quote based on your material, quantity, and specific requirements.

Yes, we can provide Certificates of Conformance (CoC), full material traceability, and any necessary inspection reports to ensure compliance with your quality and industry standards.

To begin, send us your 3D CAD file, material specifications, part quantity, finish preferences, and any required delivery timelines. This will allow us to provide a detailed quote and start the production process.

Start Your Industrial Equipment CNC Machining Project Now!

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.