Custom Over Molding Services

Robotika offers fast and efficient over molding solutions, delivering high-performance, multi-material components with rapid order turnaround and design feedback.

- Tight tolerances up to ±0.05 mm for exceptional accuracy

- Lead times as short as 7 business days for rapid tooling and sample delivery.

- Advanced material combinations for improved functionality and aesthetics.

- Rapid DFM review with wall thickness tips within 48 hours

Start a New Over Molding Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable Over Molding Services Provider from China

Robotika is a leading manufacturer specializing in Over Molding solutions, having served global clients for over a decade years. By combining two or more materials into a single component, we enhance the functionality, aesthetics, and durability of your parts. This process helps solve issues such as improving wear resistance, creating watertight seals, and combining different materials for specific mechanical properties. Whether you’re looking to improve product ergonomics, create cost-effective solutions, or optimize performance, our Over Molding services offer the flexibility and innovation needed to meet your needs.Our highly skilled engineers collaborate closely with clients, ensuring that design complexities are addressed early through Design for Manufacturability (DFM) feedback, which helps minimize costs and streamline production.

Our efficient production processes and scalable solutions ensure that we can meet both small-batch and large-volume production demands while maintaining exceptional quality and short lead times. We are proud to be a trusted partner for businesses seeking advanced Over Molding solutions that drive innovation and performance.

Our Over Molding Capabilities

Over Molding technologies includes Multi-Material Molding, Precision Engineering, Rapid Prototyping, and Advanced Material Compatibility. Our Over Molding process allows us to seamlessly combine different materials, such as thermoplastics, elastomers, and metals. We offer a variety of surface treatment options such as anodizing, powder coating, polishing, and laser marking, to enhance the functionality and appearance of the molded components. With precision machining capabilities, we ensure tolerances as tight as ±0.05 mm, using state-of-the-art inspection tools such as automated coordinate measuring machines (CMMs) to guarantee dimensional accuracy and consistency in every part we produce.

Over Molding Capabilities

Maximum Build Size

We can manufacture thin-wall parts up to 1000mm × 600mm × 500mm, suitable for small to medium-sized applications.

Material Compatibility

Our capable of molding combinations of materials such as ABS, PC, and other plastics, meeting various industrial and custom production needs.

Molding Precision

Our standard tolerance is controlled within ±0.05mm, ensuring high precision for lightweight and durable plastic components.

Surface Finishing Options

We support polishing, painting, sandblasting, laser engraving, and more for enhanced durability and aesthetics.

Delivery Time

Our standard injection molding lead time is 7-15 days, with expedited services available for urgent projects.

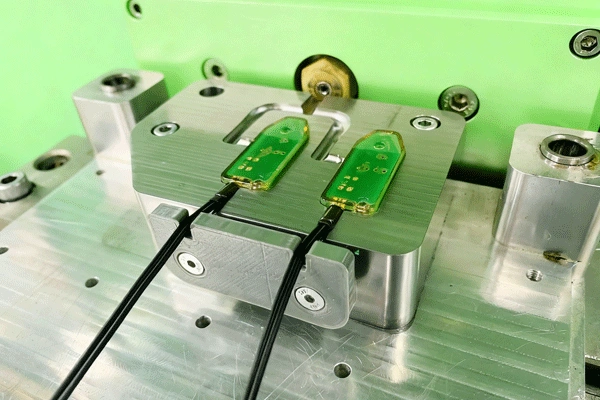

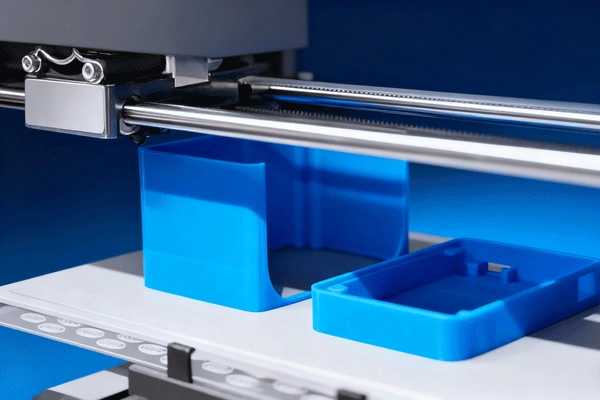

Our Latest Over Molding Products We have Manufactured

Our over-molded parts combine rigid structures with soft-touch surfaces for improved grip, durability, and user experience.

Over Molding Tolerance

| Part Type | Tolerance Range |

|---|---|

| Dimensional Tolerance | ±0.05 mm |

| Position Tolerance | ±0.05 mm |

| Surface Finish Tolerance | Ra 0.8-1.6 µm |

| Geometric Tolerance | ±0.1 mm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Over Molding Materials

ABS (Acrylonitrile-Butadiene-Styrene)

ABS is ideal for Over Molding due to its excellent mechanical properties, impact resistance, and ease of processing. It is widely used in automotive and consumer electronics for its ability to withstand shocks and provide good strength. For example, ABS is over-molded with TPE in automotive parts to provide a soft grip on controls, while maintaining structural integrity.

Lead Time: As fast as 3 days

Finishes: Raw, anodized, bead blasted, polished.

PP (Polypropylene)

PP is known for its chemical resistance, flexibility, and lightweight properties, making it a top choice for Over Molding. It is commonly used in automotive and medical applications. For example, PP can be over-molded with TPE in medical devices to provide a soft touch while maintaining the durability of the base structure.

Lead Time: As fast as 4 days

Finishes: Raw, textured, smooth.

PE (Polyethylene)

PE is popular in Over Molding due to its toughness, flexibility, and low friction properties. It is commonly used in packaging, automotive, and consumer products. For example, PE is over-molded with rubber in packaging to improve sealing and protection, especially in electronic components and consumer goods.

Lead Time: As fast as 4 days

Finishes: Raw, matte, glossy.

PVC (Polyvinyl Chloride)

PVC is durable, flexible, and offers excellent resistance to environmental stress, making it a great option for Over Molding. It is widely used in electrical applications for insulation. For instance, PVC wire connectors are often over-molded with thermoplastics to improve handling and enhance insulation properties.

Lead Time: As fast as 5 days

Finishes: Raw, matte, gloss, textured.

PC

PC (Polycarbonate) is a heat-sensitive resin that has high strength with good impact resistance, light transmission, and thermal stability. It is dimensionally stable with good fire retardancy and UV stability, being applicable for automotive components, electronic housings, medical devices, and transparent products like lenses and shields. PC can easily be molded and post-formed to attain better form and function. It is appropriate for difficult engineering applications because of its strength and flexibility.

- Production Lead Time: As fast as 7 days

- Color: Transparent, White, Black, Gray, Custom Colors Available

Stainless Steel (e.g., 304, 316)

Stainless steel is widely used in Over Molding because of its strength, corrosion resistance, and ability to withstand harsh environments. It is commonly used in medical devices and automotive parts. For instance, stainless steel fasteners are over-molded with rubber to enhance grip and reduce vibrations in mechanical systems.

Lead Time: As fast as 7 days

Finishes: Raw, passivated, polished, bead blasted.

Brass

Brass is known for its excellent machinability, corrosion resistance, and electrical conductivity. It is widely used in connectors and electrical components. Brass electrical connectors can be over-molded with thermoplastic materials to ensure electrical insulation and enhance the durability of connectors in harsh conditions.

Lead Time: As fast as 5 days

Finishes: Raw, gold plated, anodized.

Copper

Copper offers superior electrical and thermal conductivity, making it ideal for Over Molding in electrical and thermal applications. Copper heat sinks are over-molded with thermoplastics to improve thermal management and prevent damage during use.

Lead Time: As fast as 7 days

Finishes: Raw, electroplated, polished.

PEEK (Polyether Ether Ketone)

PEEK is ideal for Over Molding due to its high strength, chemical resistance, and ability to withstand high temperatures. It is widely used in aerospace, medical, and automotive industries for components that require durability and resistance to extreme conditions. For example, PEEK is over-molded with elastomers in medical devices to provide flexibility while maintaining mechanical integrity.

Lead Time: As fast as 7 days

Finishes: Raw, polished, textured.

PTFE (Polytetrafluoroethylene)

PTFE offers excellent chemical resistance, low friction, and high-temperature tolerance, making it perfect for Over Molding in critical applications. It is commonly used in sealing components and electrical parts. For instance, PTFE seals are over-molded with rubber in fluid systems to prevent leaks while maintaining high-performance standards.

Lead Time: As fast as 7 days

Finishes: Raw, matte, smooth.

PPSU (Polyphenylsulfone)

PPSU is a high-performance thermoplastic known for its exceptional heat resistance, toughness, and chemical stability. It is widely used in the medical and automotive sectors. For example, PPSU is over-molded with rubber in medical components to enhance durability and comfort without compromising safety.

Lead Time: As fast as 6 days

Finishes: Raw, polished, matte.

PBT (Polybutylene Terephthalate)

PBT is known for its excellent mechanical properties, high strength, and low moisture absorption, making it ideal for electrical and automotive applications. For instance, PBT is over-molded with elastomers to create durable connectors in automotive electrical systems that are both heat and moisture resistant.

Lead Time: As fast as 5 days

Finishes: Raw, gloss, textured.

Finishing Options for Over Molding

| Name | Description | Can Be Applied with | Applicable Materials |

|---|---|---|---|

Anodizing

Anodizing

|

A process that thickens the natural oxide layer on metal surfaces, enhancing corrosion resistance and surface hardness. | Metal surfaces | Aluminum, Steel |

Powder Coating

Powder Coating

|

A dry coating method that applies a powdered paint, followed by heat curing for a durable, aesthetic finish. | Metal and plastic substrates | Aluminum, Steel, ABS, PP |

Polishing

Polishing

|

A process to create a smooth, reflective surface, reducing surface roughness and enhancing appearance. | Metal and plastic surfaces | Aluminum, Stainless steel, PEEK, ABS |

Bead Blasting

Bead Blasting

|

A technique using abrasive media to smooth and texture the surface, creating a matte finish. | Metal and plastic components | Aluminum, Stainless steel, ABS |

Electroplating

Electroplating

|

A process that deposits a metal coating through electrochemical means, improving corrosion resistance and aesthetics. | Metal substrates | Brass, Stainless steel, Copper |

Laser Marking/Engraving

Laser Marking/Engraving

|

A process using laser beams to etch text, logos, or designs into the surface, offering precision and branding. | Metal and certain plastics | Stainless steel, Aluminum, PEEK |

Texturing

Texturing

|

Adds a patterned texture to the surface, improving grip and aesthetic appeal. | Plastic components | ABS, PP, PE |

Chrome Plating

Chrome Plating

|

A process that applies a thin layer of chromium for enhanced hardness, corrosion resistance, and aesthetics. | Metal surfaces | Steel, Brass |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Over Molding Design Guide

In this guide to overmolding, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

Over Molding Service FAQs

How long does it take to get a quote for my Over Molding project?

We can provide a quote within 24 to 48 hours, depending on the complexity of your project. You’ll receive a detailed breakdown of pricing, lead time, and material options.

What is the minimum order quantity (MOQ) for Over Molding parts?

Our minimum order quantity varies based on the complexity of your part and the materials used. Generally, it starts at 500 pieces for standard parts, but we also handle smaller quantities for prototypes and testing.

What materials can you use for Over Molding?

We work with a wide range of materials including general-purpose plastics like ABS and PP, high-performance plastics like PEEK and PTFE, and metals like aluminum and stainless steel. We also offer elastomers and thermoplastic rubbers for the over-molded layer.

Can I get a prototype before committing to full production?

Absolutely! We offer rapid prototyping services to help you test your design before moving to full-scale production. It ensures you get the exact results you need.

What are the typical tolerances for Over Molding?

We can achieve tolerances as tight as ±0.05 mm for most Over Molding parts, ensuring high precision and consistency in both dimensions and fit.

What surface finishes are available for Over Molding?

We offer a variety of finishes including anodizing, powder coating, polishing, bead blasting, and laser engraving to enhance the durability, appearance, and functionality of your parts.

Can you handle both small and large production runs?

Yes! We handle both small runs for prototyping and large-scale production, ensuring flexibility to meet your specific needs regardless of order size.

What industries do you serve with your Over Molding services?

We serve a wide range of industries including automotive, medical, electronics, consumer products, and more, providing customized Over Molding solutions to meet diverse application requirements.

Are You Looking for Over Molding Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.