Custom Plastic Injection Molding Services

We specialize in both rapid prototyping and high-volume production of Plastic Injection Molding. Get an online quote with free analysis in hours for quality parts within days.

- Tolerances controlled within ±0.01mm

- boast industry-leading delivery times

- 100+ materials including ABS, PC, PP, POM, Nylon, and more

- ISO 9001:2015 Certified

Start a New Plastic Injection Molding Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable Plastic Injection Molding Services Provider from China

Robotika has been a professional plastic injection molding manufacturer in China for over a decade years, offering end-to-end solutions from rapid prototyping to large-scale production. Equipped with advanced injection molding machines ranging from 30 to 1,000 tons, as well as in-house CNC milling capabilities, we can produce high-precision plastic components with consistent quality. Our integrated production setup allows us to handle complex designs, tight tolerances, and fast turnaround requirements for diverse industry needs. We support customers from the early design stage with professional DFM (Design for Manufacturability) feedback. By combining precise mold fabrication, optimized molding parameters, and material expertise, we help clients reduce lead times, minimize production risks, and lower overall costs. Whether it’s a functional prototype, low-volume batch, or high-volume manufacturing run, our process ensures accuracy, repeatability, and efficiency.

Robotika produces tens of thousands of injection molded parts each year for industries including automotive, electronics, medical devices, consumer goods, and industrial equipment. Our proven track record of serving global customers — from innovative startups to established multinational brands — enables us to provide a stable, long-term supply chain solution tailored to each client’s unique requirements.

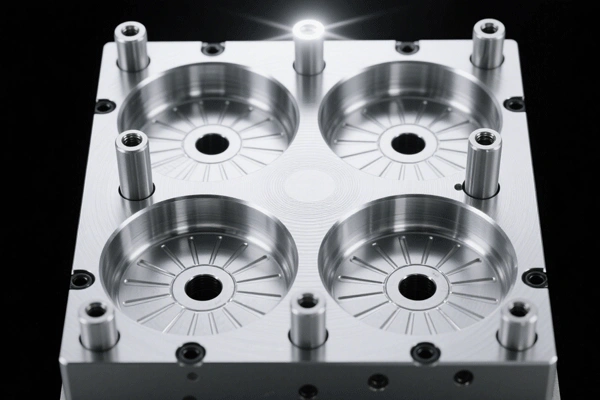

Our Plastic Injection Molding Capabilities

Robotika capabilities cover Standard Injection Molding, Injection Molding Tooling, Overmolding, and Insert Molding. We work with a wide variety of thermoplastics and engineering resins such as ABS, PC, PP, PEEK, PA, PMMA, and reinforced composites, allowing us to meet the specific performance, durability, and aesthetic requirements of each application. We provide multiple surface finishing options for molded parts, including texture etching, high-gloss polishing, painting, plating, and laser engraving. Our molding processes can achieve tight tolerances of ±0.05 mm for most standard parts, and even tighter for precision-engineered components, ensuring optimal fit and performance. All parts undergo rigorous quality inspections using advanced equipment like coordinate measuring machines (CMMs) and vision systems to guarantee dimensional accuracy and consistency before delivery.

Plastic Injection Molding Capabilities

Maximum Build Size

We can manufacture plastic parts up to 1200 × 1000 × 500 mm, suitable for small to medium-sized applications.

Material Compatibility

We offer plastic injection molding with high-flow polymers, including ABS, PC, PP, PEEK, PA, PMMA materials, meeting diverse industrial and custom production needs.

Molding Precision

Our standard tolerance is controlled within ±0.05mm, ensuring high precision for lightweight and durable plastic components.

Secondary Operations

We support mold texturing, pad printing, laser engraving, threaded inserts, and basic assembly to enhance the functionality and aesthetics of your products.

Delivery Time

Our standard injection molding lead time is 7-15 days, with expedited services available for urgent projects.

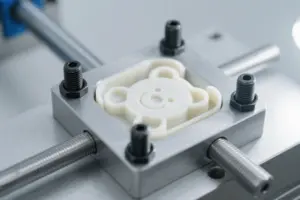

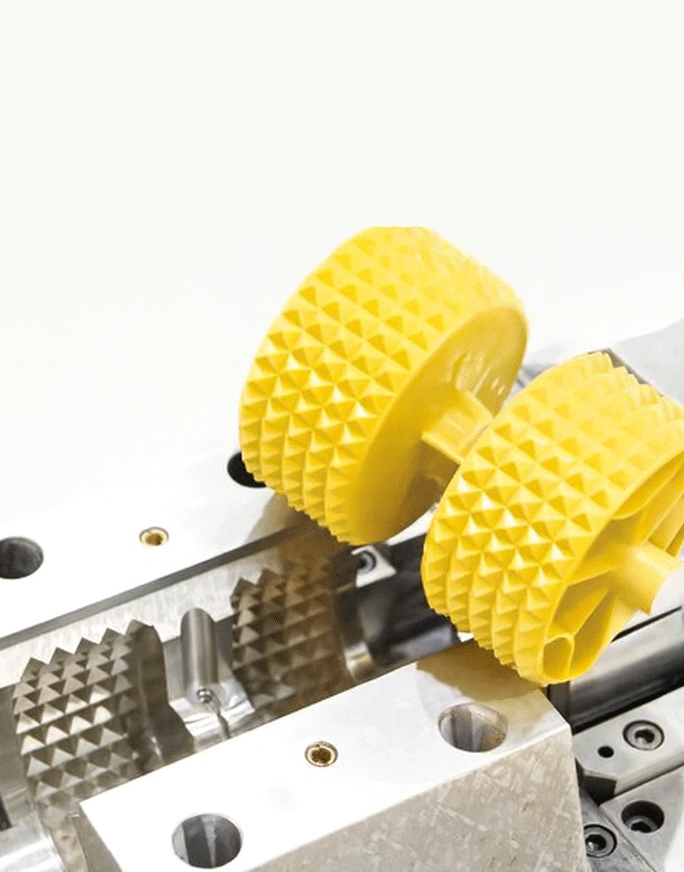

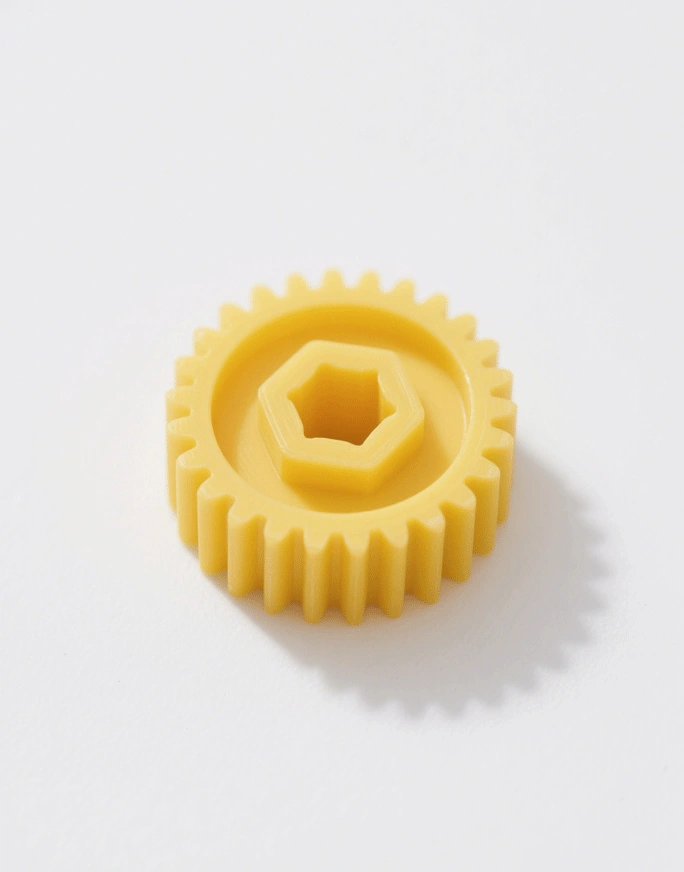

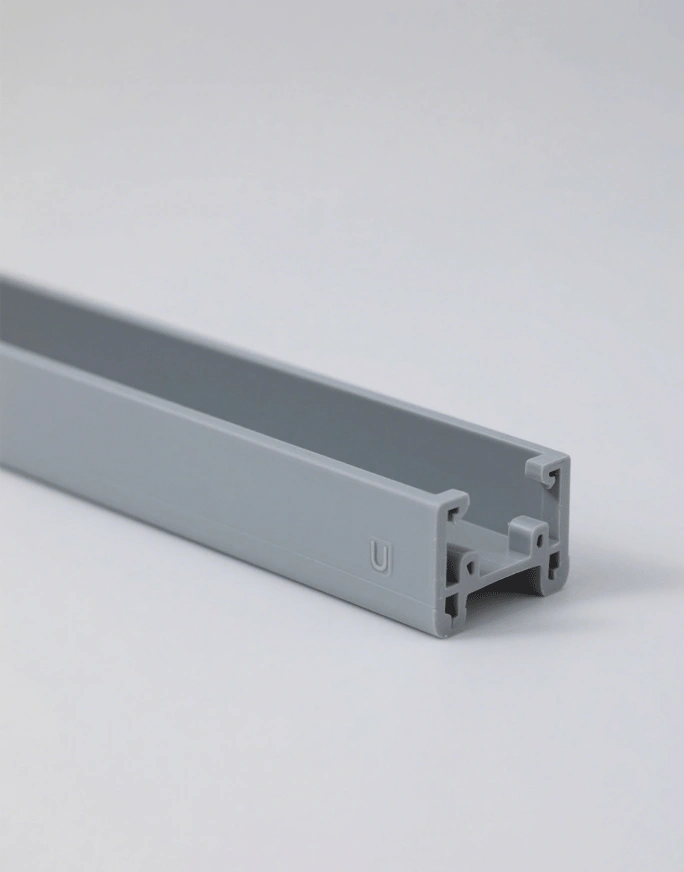

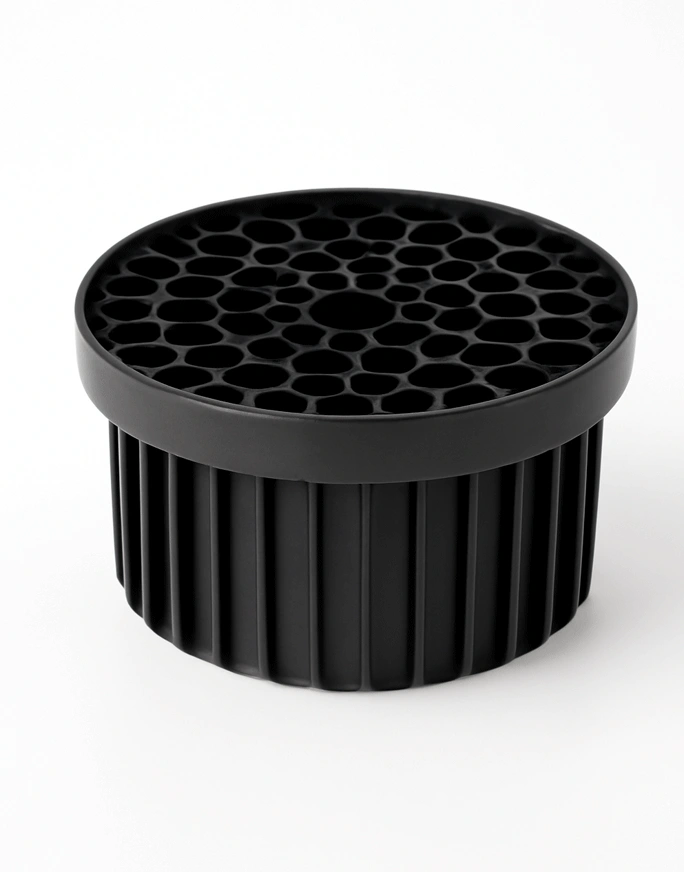

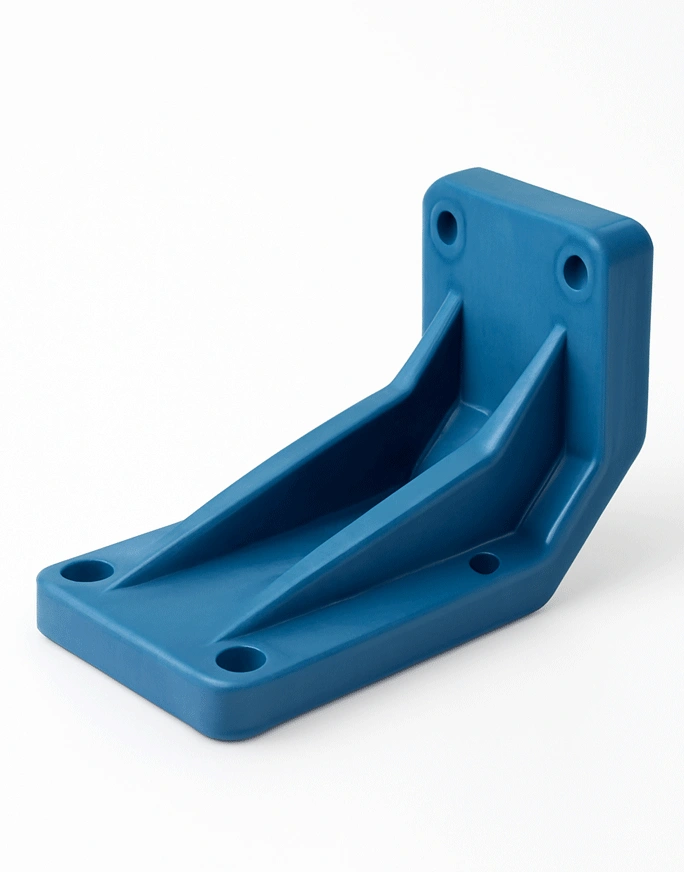

Our Latest Plastic Injection Molding Products We Have Manufactured

From concept validation to mass production, each part reflects our tooling precision and molding expertise.

Plastic Injection Molding Tolerance

| Part Type | Tolerance Range |

|---|---|

| Standard Injection Molding | +/- 0.1 mm to +/- 0.2 mm |

| Precision Injection Molding | +/- 0.05 mm or tighter |

| Large Parts | +/- 0.2 mm to +/- 0.5 mm |

| Thin-Walled Injection Parts | +/- 0.2 mm |

- *The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Plastic Injection Molding Materials

ABS

ABS (Acrylonitrile Butadiene Styrene) is a commodity injection-molding thermoplastic for broad use due to its impact strength, toughness, and processability. It possesses good mechanical features, thermal stability, and chemical inertness and is thus used in car parts, household appliances, and consumer products. ABS also is easily paintable, platable, or texturable for added beauty and functionality. Its cost efficiency and all-around technological properties make it best popular for durable plastic components.

• Production Lead Time: Up to 7 days

• Finishes: Raw, anodized, bead blasted, polished

PP

PP (Polypropylene) is a lightweight, flexible thermoplastic widely used in injection molding for its excellent chemical resistance, fatigue strength, and low moisture absorption. It offers good impact resistance, thermal stability, and electrical insulation properties, making it ideal for automotive components, medical devices, packaging, and household goods. PP is also highly recyclable and can be modified with additives to enhance its mechanical properties. Its affordability and versatility make it a preferred choice for a wide range of applications.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PE

PE (Polyethylene) is a durable and flexible thermoplastic widely used in injection molding for its excellent impact resistance, chemical stability, and moisture resistance. It is lightweight, has good electrical insulation properties, and is available in different densities (LDPE, HDPE) to suit various applications. PE is commonly used in packaging, automotive components, piping, and consumer goods. Its low cost, ease of processing, and recyclability make it a preferred material for both industrial and commercial products.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PS

PS (Polystyrene) is a rigid and lightweight thermoplastic widely used in injection molding due to its excellent clarity, ease of processing, and affordability. It offers good dimensional stability, electrical insulation, and chemical resistance, making it ideal for packaging, disposable containers, consumer electronics, and household products. PS is available in both general-purpose (GPPS) and high-impact (HIPS) variants, catering to different strength and flexibility requirements. Its cost-effectiveness and versatility make it a popular choice for various applications.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PVC

PVC (Polyvinyl Chloride) is a durable and versatile thermoplastic widely used in injection molding due to its excellent chemical resistance, flame retardancy, and mechanical strength. It offers good impact resistance, weatherability, and electrical insulation properties, making it ideal for pipes, fittings, medical devices, automotive parts, and consumer goods. PVC can be formulated as rigid (RPVC) or flexible (FPVC) to suit different application needs. Its cost-effectiveness and adaptability make it a preferred material for industrial and commercial products.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PC

PC (Polycarbonate) is a heat-sensitive resin that has high strength with good impact resistance, light transmission, and thermal stability. It is dimensionally stable with good fire retardancy and UV stability, being applicable for automotive components, electronic housings, medical devices, and transparent products like lenses and shields. PC can easily be molded and post-formed to attain better form and function. It is appropriate for difficult engineering applications because of its strength and flexibility.

- Production Lead Time: As fast as 7 days

- Color: Transparent, White, Black, Gray, Custom Colors Available

PA

PA (Polyamide), commonly known as Nylon, is a strong and durable engineering thermoplastic with excellent mechanical strength, wear resistance, and chemical stability. It offers high impact resistance, good thermal performance, and low friction, making it ideal for automotive components, industrial gears, bearings, and consumer goods. PA is available in various grades (PA6, PA66, PA12) and can be reinforced with glass fiber for enhanced strength. Its versatility and reliability make it a preferred material for demanding applications.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PET

PET (Polyethylene Terephthalate) is a strong and lightweight thermoplastic known for its excellent mechanical properties, chemical resistance, and dimensional stability. It offers high stiffness, low moisture absorption, and good heat resistance, making it ideal for food packaging, automotive components, electrical insulators, and industrial applications. PET can be reinforced with glass fiber for enhanced strength and wear resistance. Its durability, recyclability, and versatility make it a widely used material in injection molding.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PEEK

PEEK, or Polyether Ether Ketone, is a high-temperature thermoplastic offering enhanced mechanical toughness, thermal stability, and chemical inertness. It is more resistant to wear, features less friction, and enhanced dimensional stability and can be used in aerospace, medical, automotive, and industrial applications. It is biocompatible, highly resistant to hostile environments, and metal-substitutable-like in hostile environments. Its enhanced properties make it the superior option for precision-engineered components that demand reliability and endurance.

- Production Lead Time: As fast as 7 days

- Color: Natural, Black, Gray, Custom Colors Available

LCP

LCP is known for its high strength, heat resistance, and thin-wall molding capability, making it perfect for micro-components and electronic connectors. It is widely used in smartphone housings, micro gears, and LED reflectors. For example, ultra-thin electronic casings and fine-pitch connectors use LCP to maintain performance while achieving compact designs.

- Mill Lead Time: Up to 5 days

- Color: Natural, black, custom

TPU

TPU is flexible, wear-resistant, and has excellent elasticity, making it ideal for protective casings, medical tubing, and shock-absorbing components. Examples include smartwatch bands, soft-touch phone cases, and flexible medical catheter tubes, where TPU provides durability and comfort.

- Mill Lead Time: Up to 4 days

- Color: Transparent, black, custom colors

PPS

PPS (Polyphenylene Sulfide) is a heat-resistant high-performance thermoplastic polymer with superior heat resistance, chemical stability, and mechanical strength. PPS is highly dimensionally stable, fire-resistant, and water-resistant, and hence suitable for usage in the automobile, aerospace, electrical, and industrial sectors. PPS is generally used in high-heat-resistant components and challenging applications such as pump housings, electric connectors, and mechanical components of high precision. Its reliability and long term performance make it the industry best solution for challenging engineering applications.

- Production Lead Time: As fast as 7 days

- Color: Natural, Black, Gray, Custom Colors Available

Finishing Options for Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Chem Film | Suitable for certain plastic alloys (e.g., plastics with aluminum base) | Transparent gold, metallic sheen | Commonly used with plating, painting, and other finishing options |

|

Electroless Nickel Plating | Suitable for certain plastics (e.g., PC, ABS) | Silver, metallic sheen | Can be combined with painting, electroplating, and other surface finishes |

|

Hand Polishing | Suitable for various plastics (e.g., PC, ABS) | Natural color or smooth, transparent surface | Combined with sandblasting, painting, and mirror polishing for improved appearance |

|

Media Blasting | Various plastics (e.g., ABS, PP, PC) | Matte or rough texture | Often used with painting, texturing, or sandblasting for aesthetic or functional purposes |

|

Nickel Plating | Various plastics (e.g., ABS, PC) | Nickel, metallic sheen | Often used with painting, heat transfer printing, and UV coating |

|

Powder Coating Services | Various plastics (e.g., ABS, PC, PP) | Various colors (customizable) | Often combined with electroplating or painting for enhanced corrosion and wear resistance |

|

Tumbling | Various plastics (e.g., ABS, PP, PE) | Natural color, matte finish | Typically used with sandblasting, painting, or mirror polishing for surface refinement |

|

Vapor Polishing | Suitable for transparent plastics (e.g., PMMA, PC) | Glossy, transparent, colorless | Often combined with mirror polishing or electroplating for clarity and smooth finish |

|

Zinc Plating | Suitable for certain plastic/metal composite materials | Zinc color, silver | Combined with electroplating or painting, improving corrosion resistance and aesthetics |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Plastic Injection Molding Design Guide

In this guide to plastic injection molding, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

Plastic Injection Molding Service FAQs

What is the minimum order quantity (MOQ) for plastic injection molding?

We can accommodate both small and large orders. We’re flexible based on your project needs.

How long will it take to produce my injection molded parts?

Production times vary depending on the complexity and quantity of the parts, but we typically deliver within 10-15 business days after mold approval.

What materials can you work with?

We offer a wide range of materials, including ABS, PP, PC, PEEK, PA, PMMA, and more. Let us know your specific needs, and we’ll recommend the best material for your project.

Can you produce small batch runs?

Yes, we can produce small batch runs starting from 500-1,000 parts. This is ideal for testing, low-volume production, or pilot runs.

How do I approve the mold before production begins?

Once the mold design is ready, we will provide you with a 3D rendering or sample for approval. Production starts only after your confirmation.

Do you offer prototyping before production?

Yes, we offer rapid prototyping services to ensure your design meets your expectations before we begin mass production. This helps avoid costly mistakes later in the process.

Can you help with designing the mold?

Yes, our experienced engineering team provides Design for Manufacturability (DFM) feedback to help optimize your design for injection molding. We can also assist with mold design if needed.

Are You Looking for Plastic Injection Molding Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.