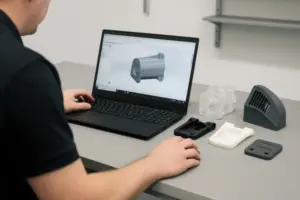

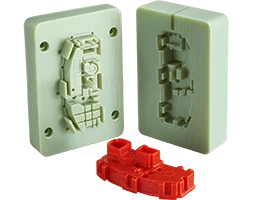

Custom Plastic Molding Prototype Services

Robotika provides professional plastic molding prototype services with quick turnaround, design optimization support.

- Achieve tolerances as tight as ±0.02 mm for most plastic parts

- Prototypes can be produced within days, enabling faster design validation and shorter product development cycles.

- Supports a wide range of plastics.

- 24/7 engineering support

Start a New Plastic Molding Prototype Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable Plastic Molding Prototype Services Provider from China

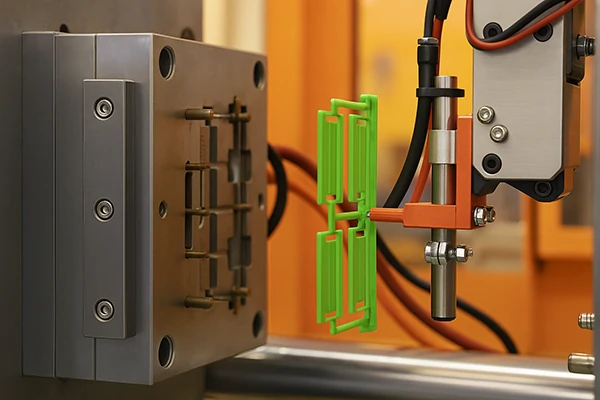

Robotika is a trusted manufacturer in China specializing in plastic molding prototype services. With years of industry experience, Robotika has produced thousands of molded prototypes and custom parts for global clients. Our plastic molding prototype services focus on speed, precision, and flexibility. We support a wide selection of engineering plastics and provide surface finishing options that closely replicate end-use parts. By delivering prototypes within days, we help customers accelerate product development, test functionality, and validate designs before investing in full-scale tooling. Whether solving issues of complex geometries, tight tolerances, or material performance, our prototyping service bridges the gap between design and mass production, reducing risks and saving costs.

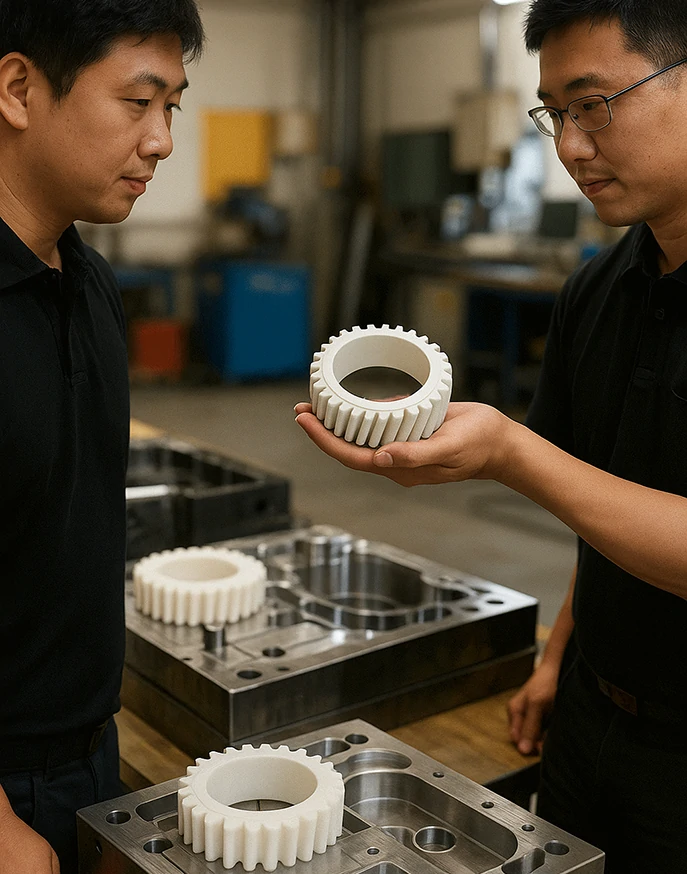

Our services cater to diverse industries such as automotive, aerospace, electronics, consumer products, and medical devices. By combining technical expertise with flexible production capacity, we help startups, SMEs, and established enterprises bring their ideas to life with precision, speed, and consistency.

Our Plastic Molding Prototype Capabilities

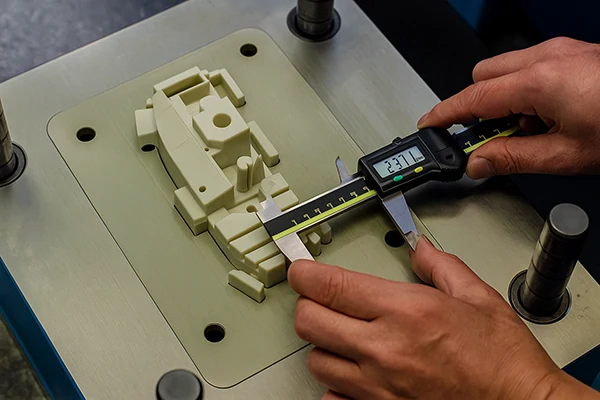

Robotika provides complete plastic molding prototype services with strong technical capabilities, including prototype design, inspection and validation, precision machining and tooling, and surface finishing & post-processing. Our facility supports both plastic and hybrid prototype production, working with a wide range of engineering plastics such as ABS, PC, PP, PMMA, nylon, and high-performance polymers like PEEK. For finishing, we provide multiple options including polishing, texturing, sandblasting, painting, and coating, ensuring prototypes closely replicate end-use products.

Our machining and molding operations achieve tolerances as tight as ±0.02 mm for most plastic parts. By combining speed, precision, and flexibility, our Plastic Molding Prototype Services help customers validate designs, test functionality, and reduce risks before scaling to mass production. Every prototype undergoes rigorous quality inspection with advanced equipment such as coordinate measuring machines (CMMs), guaranteeing accuracy and consistency across every stage of development.

Plastic Molding Prototype Capabilities

Maximum Build Size

We offer molding assistance with parts measuring up to 500mm × 400mm × 300mm, accommodating various sizes of projects.

Material Versatility

We support a wide range of plastics (ABS, PC, PP, PMMA, nylon, etc.) and can simulate end-use properties for both functional and visual testing.

High Precision & Tight Tolerances

Our advanced CNC machining and molding equipment ensures dimensional accuracy up to ±0.02 mm, suitable for complex and functional parts.

Surface Finishing Options

We support texturing, polishing, silk-screen printing, UV coating, and electroplating for enhanced aesthetics and functionality.

Delivery Time

Our standard injection molding lead time is 7-15 days, with expedited services available for urgent projects.

Our Latest Plastic Molding Prototype Products We have Manufactured

Our production-grade plastic prototypes validate design, fit, and function before mass production.

Plastic Molding Prototype Tolerance

| Part Type | Tolerance Range |

|---|---|

| CNC Machining (Plastic) | ±0.05 mm – ±0.10 mm |

| Plastic Injection Prototypes | ±0.10 mm – ±0.20 mm |

| Vacuum Casting (Urethane) | ±0.15 mm – ±0.30 mm |

| 3D Printing (SLA/SLS/FDM) | ±0.20 mm – ±0.50 mm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Plastic Molding Prototype Materials

ABS

ABS is one of the most popular materials for Plastic Molding Prototype Services due to its excellent impact resistance, mechanical strength, and ease of processing. It allows manufacturers to produce prototypes with good dimensional stability and smooth surfaces, making it suitable for both functional and cosmetic testing. ABS prototypes are commonly used in automotive dashboards, consumer electronics housings, and household appliance components, helping customers validate both form and performance before mass production.

Mill Lead Time: As fast as 3 days

Finishes: Raw, textured, painted, polished

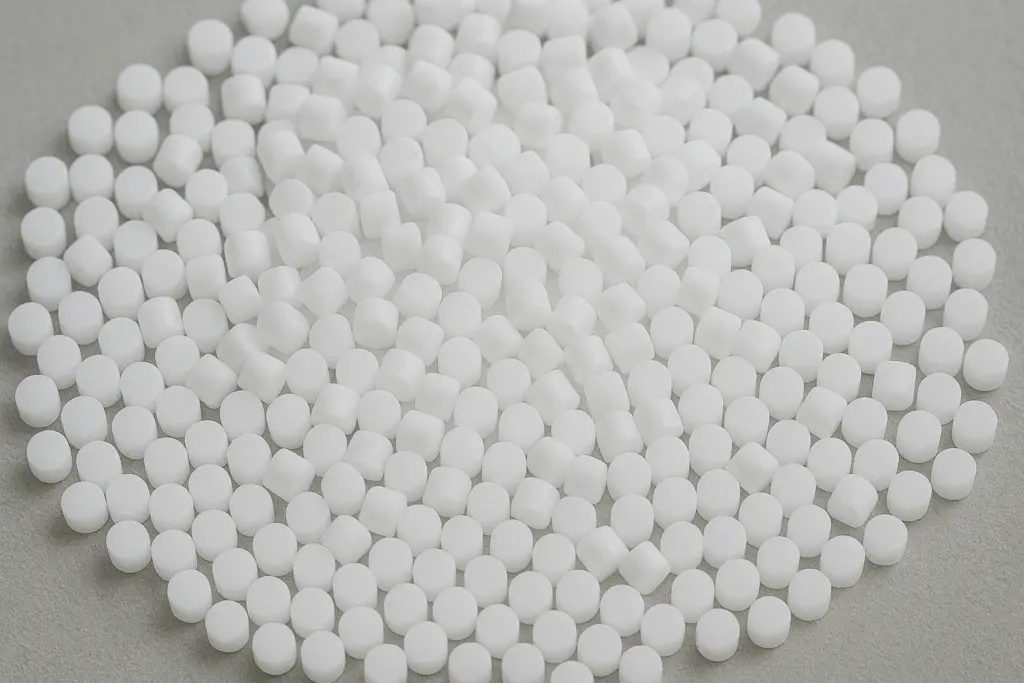

Polypropylene (PP)

Polypropylene is ideal for Plastic Molding Prototype Services because of its lightweight, flexibility, and outstanding chemical resistance. It is often chosen for prototypes that require durability and resilience under stress. PP prototypes are widely used in packaging, laboratory equipment, and automotive components such as interior panels and battery cases. For example, a prototype container or car trim part can be molded from PP to test resistance to chemicals and wear before final production.

Mill Lead Time: As fast as 3–5 days

Finishes: Raw, textured, painted

Polyethylene (PE)

Polyethylene is widely used in Plastic Molding Prototype Services thanks to its low cost, toughness, and excellent resistance to moisture. It is ideal for prototypes that require lightweight strength and flexibility. PE prototypes are often applied in packaging films, consumer containers, and household products. For example, prototype bottles, storage bins, and flexible packaging solutions are commonly molded from PE to validate design performance in everyday usage scenarios before mass manufacturing.

Mill Lead Time: As fast as 4 days

Finishes: Raw, textured, painted

Polystyrene (PS)

Polystyrene is commonly applied in Plastic Molding Prototype Services due to its rigidity, cost-effectiveness, and ease of molding. It is especially suitable for prototypes requiring transparency or lightweight structures. PS prototypes are widely used in disposable packaging, display cases, and consumer product housings. For instance, clear prototype covers and lightweight trays can be molded from PS to evaluate design aesthetics and practicality in early testing stages.

Mill Lead Time: As fast as 4 days

Finishes: Raw, polished, painted

Acrylic (PMMA)

Acrylic is a popular material for Plastic Molding Prototype Services because of its excellent optical clarity, scratch resistance, and weatherability. It is particularly suitable for prototypes that require transparency and a high-quality surface finish. Acrylic prototypes are often applied in lighting covers, automotive lenses, and display products. For instance, prototype lamp covers, transparent panels, or decorative components are molded from PMMA to test visual aesthetics and durability before production.

Mill Lead Time: As fast as 5 days

Finishes: Raw, polished, UV-coated

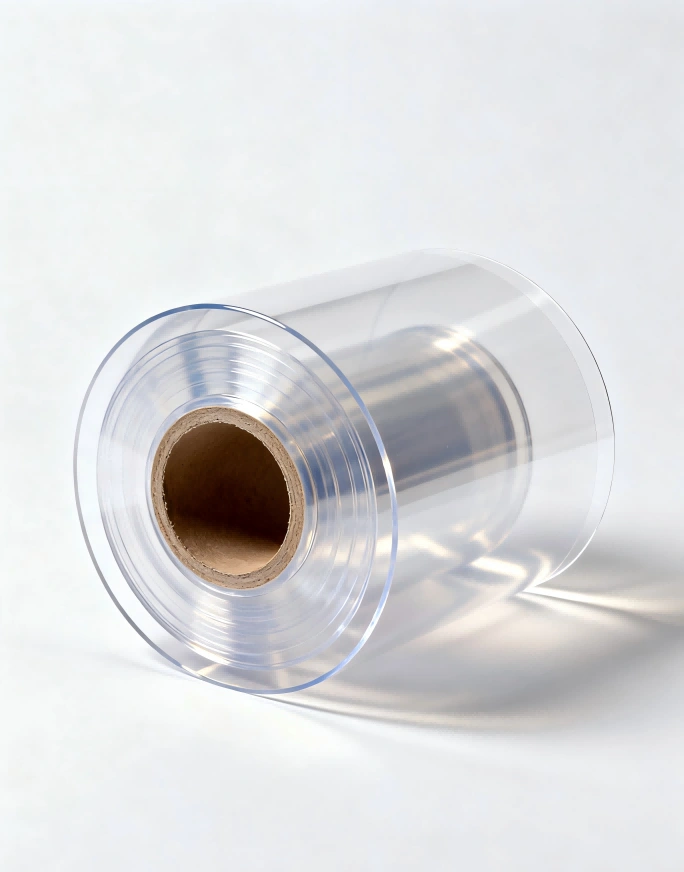

Polycarbonate (PC)

Polycarbonate is widely used in Plastic Molding Prototype Services thanks to its exceptional impact resistance, high strength, and optical clarity. It is ideal for prototypes requiring both mechanical performance and visual appeal. PC is often applied in safety equipment, transparent housings, and automotive lighting. For example, prototype protective covers, transparent machine guards, and headlamp lenses are frequently made from PC to test strength, clarity, and design aesthetics before final production.

Mill Lead Time: As fast as 4 days

Finishes: Raw, polished, UV-coated

Nylon (PA6/PA66)

Nylon is a strong and versatile material for Plastic Molding Prototype Services, offering excellent wear resistance, toughness, and fatigue strength. It performs well in prototypes that must endure mechanical stress or repeated use. Nylon prototypes are commonly used in gears, bushings, hinges, and automotive components. For instance, a prototype gear set or hinge mechanism can be molded from nylon to validate strength and durability during functional testing before large-scale manufacturing.

Mill Lead Time: As fast as 5 days

Finishes: Raw, dyed, polished

PEEK (Polyetheretherketone)

PEEK is a premium material in Plastic Molding Prototype Services, known for its outstanding thermal stability, chemical resistance, and mechanical strength. It is especially suitable for demanding applications in aerospace, medical, and automotive industries. PEEK prototypes are often used for testing engine components, surgical tools, and electronic connectors. For example, a prototype implantable device or high-heat engine bracket is molded from PEEK to ensure safety, precision, and reliability before moving to mass production.

Mill Lead Time: As fast as 7 days

Finishes: Raw, polished, machined

PPS (Polyphenylene Sulfide)

PPS is ideal for Plastic Molding Prototype Services due to its excellent chemical resistance, flame retardancy, and dimensional stability under high temperatures. It is often selected for prototypes used in electrical, electronic, and automotive applications. PPS prototypes are applied in connectors, pump components, and sensor housings. For instance, a prototype automotive electrical connector can be molded from PPS to validate heat resistance and dimensional precision under real-world conditions.

Mill Lead Time: As fast as 6 days

Finishes: Raw, polished, coated

PTFE (Teflon)

PTFE is a highly functional material in Plastic Molding Prototype Services because of its outstanding non-stick properties, low friction, and extreme chemical resistance. It is commonly used in prototypes that must perform under harsh conditions or in sealing applications. PTFE prototypes are applied in gaskets, seals, bearings, and medical devices. For example, a prototype chemical-resistant seal or low-friction bearing is molded from PTFE to test performance in demanding environments before final production.

Mill Lead Time: As fast as 6–7 days

Finishes: Raw, machined, coated

Finishing Options for Plastic Molding Prototype

| Name | Description | Can Be Applied with | Applicable Materials |

|---|---|---|---|

Polishing

Polishing

|

Creates a smooth, glossy surface, often used for transparent or cosmetic parts. | CNC machining, injection molding | ABS, PC, PMMA, Acrylic, Nylon |

Texturing

Texturing

|

Adds patterns or matte effects to improve grip or aesthetics. | Injection molding, painting | ABS, PP, PC, Nylon |

Painting/Coating

Painting/Coating

|

Provides color, UV protection, or improved surface durability. | Custom ColorsSpray coating, manual painting | ABS, PC, PP, PMMA |

Sandblasting

Sandblasting

|

Produces a uniform matte or frosted surface, ideal for functional testing. | Custom ColorsCNC machining, molded prototypes | ABS, PC, Nylon, PEEK |

Anodizing (for Aluminum molds/parts)

Anodizing (for Aluminum molds/parts)

|

Enhances corrosion resistance and gives colored surface finish. | CNC machining, mold tooling | Aluminum |

Electroplating

Electroplating

|

Adds a thin metallic layer for improved wear resistance and aesthetics. | Post-processing after molding | ABS, PC |

Laser Engraving

Laser Engraving

|

Adds logos, serial numbers, or functional markings with precision. | CNC machining, injection molded parts | ABS, PC, Nylon, Aluminum inserts |

Dyeing/Coloring

Dyeing/Coloring

|

Changes base resin color to match branding or improve appearance. | Injection molding, post-processing | Nylon, ABS, PC, PP |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Plastic Molding Prototype Design Guide

In this guide to plastic molding prototype, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

Plastic Molding Prototype Service FAQs

What is your minimum order quantity (MOQ) for prototypes?

We accept single-piece prototype orders, so you can test your design before scaling to production.

How fast can I get a prototype?

Standard lead time is 3–7 days, depending on material and complexity. Rush service is also available.

Can I choose different materials for my prototype?

Yes, we offer a wide range of plastics (ABS, PC, PP, Nylon, PEEK, etc.) and even metals like aluminum and stainless steel.

Do you provide surface finishing for prototypes?

Absolutely. Options include polishing, texturing, painting, sandblasting, and more to match production-quality parts.

Can you provide DFM feedback before production?

Yes, our engineering team reviews your design and provides recommendations to avoid costly errors in later stages.

How do you ensure quality for prototypes?

All parts undergo dimensional inspection and testing, with tolerances up to ±0.02 mm depending on the process.

Do you ship prototypes internationally?

Yes, we deliver prototypes worldwide via DHL, FedEx, or UPS with door-to-door service.

Are You Looking for Plastic Molding Prototype Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.