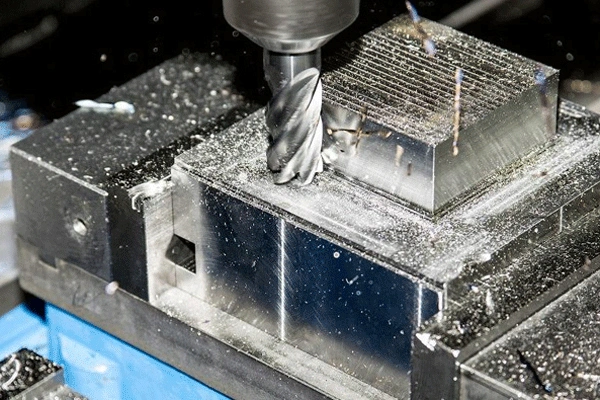

On-Demand Precision Machining Services

From prototypes to production, our precision machining ensures exceptional accuracy, premium finishes, and rapid delivery.

- Tolerance down to 0.005mm

- standard machining lead time 7-15 days

- 100+ plastic and metal materials available

- ISO 9001:2015 Certified

Start a New Precision Machining Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable Precision Machining Services Provider from China

Robotika is a professional precision machining manufacturer in China, specializing in ultra-complex geometries, tight tolerance assemblies, and mission-critical applications. Our expertise covers not only multi-axis machining but also precision jig & fixture manufacturing, high-accuracy mold tooling, and custom assembly components that demand flawless fit and repeatability. our precision approach ensures tolerances as tight as 0.001-0.005 mm, verified through advanced CMM and optical inspection systems. Moreover, our DFM services help clients to optimize designs and avoid costly errors early. We also offer a full suite of surface finishes—from passivation and plating to polishing and bead blasting—so that parts not only meet functional requirements but also achieve excellent aesthetics.

Robotika serves industries including aerospace, automotive, medical devices, electronics, and industrial equipment. Whether you need a single functional prototype, small-batch production, or mass manufacturing of custom parts, our machining expertise, reliable capacity, and fast delivery times ensure you get parts that meet your design, performance, and budget goals.

Our Precision Machining Capabilities

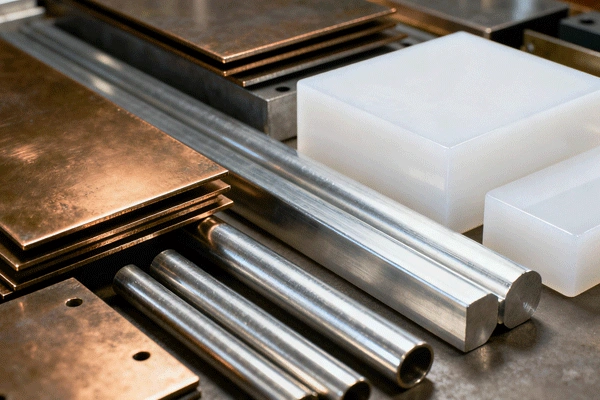

Robotika provides advanced precision machining solutions that include multi-axis machining expertise, ultra-tight tolerance control, comprehensive surface finishing options and Material versatility. Our material capabilities cover a wide range of metals such as aluminum, stainless steel, titanium, brass, and copper alloys, as well as engineering plastics like PEEK, PPSU, PTFE, nylon, and acetal (POM). To enhance both performance and aesthetics, we offer a complete range of surface finishing and post-processing options, including Passivation, Bead Blasted, Electropolishing, Powder Coating, Nickel/Zinc Plating, Black Oxide, Polishing and Painting. Supported by high-precision inspection systems such as CMM and optical measurement, our machining operations can consistently achieve tolerances as tight as ±0.005 mm for metals and ±0.01 mm for plastics, ensuring every part meets exact design specifications and industry standards.

Precision Machining Capabilities

Maximum Machining Size

We up to 1000mm × 600mm × 500mm, suitable for small to medium-sized parts.

Material Compatibility

Our capable of machining aluminum, stainless steel, brass, copper, carbon steel, and engineering plastics (POM, ABS, Nylon, PEEK, etc.), meeting various industrial and custom production needs.

Machining Accuracy

Our standard tolerance controlled within ±0.005 mm – ±0.01 mm, ensuring high precision for mechanical components, electronic parts, and industrial applications.

Surface Finishing Options

We support Passivation, Bead Blasted, Electropolishing, Powder Coating, Nickel/Zinc Plating, Black Oxide, Polishing, Painting for enhanced aesthetics and functionality.

Delivery Time

Our standard precision machining lead time is 5-7 days, with expedited service available for urgent projects.

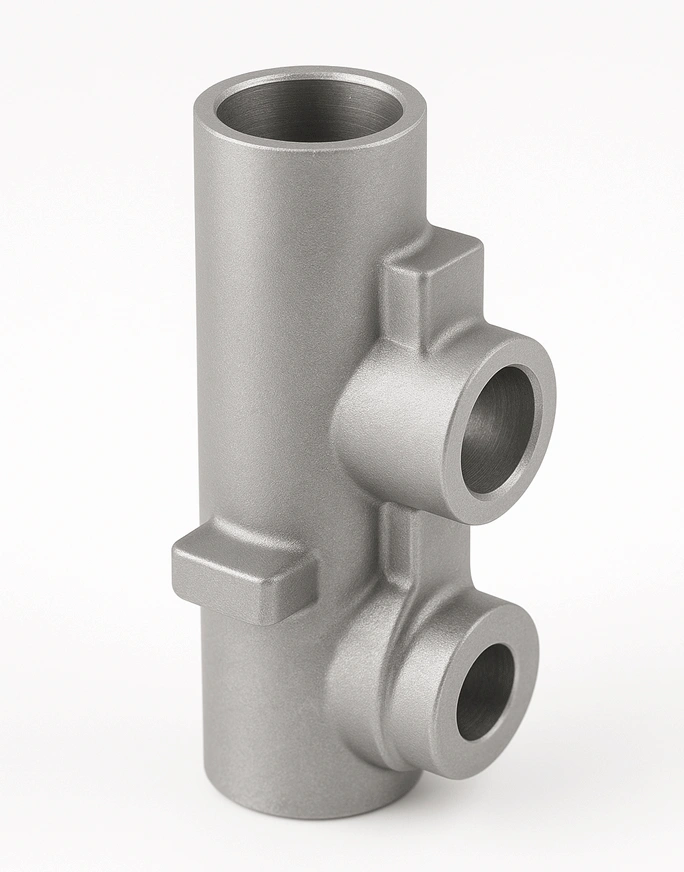

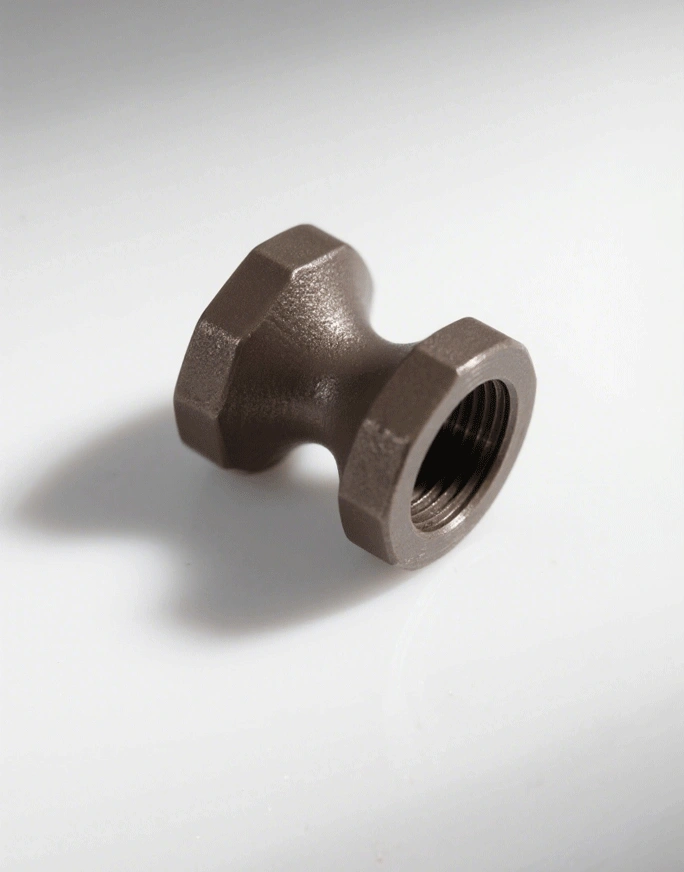

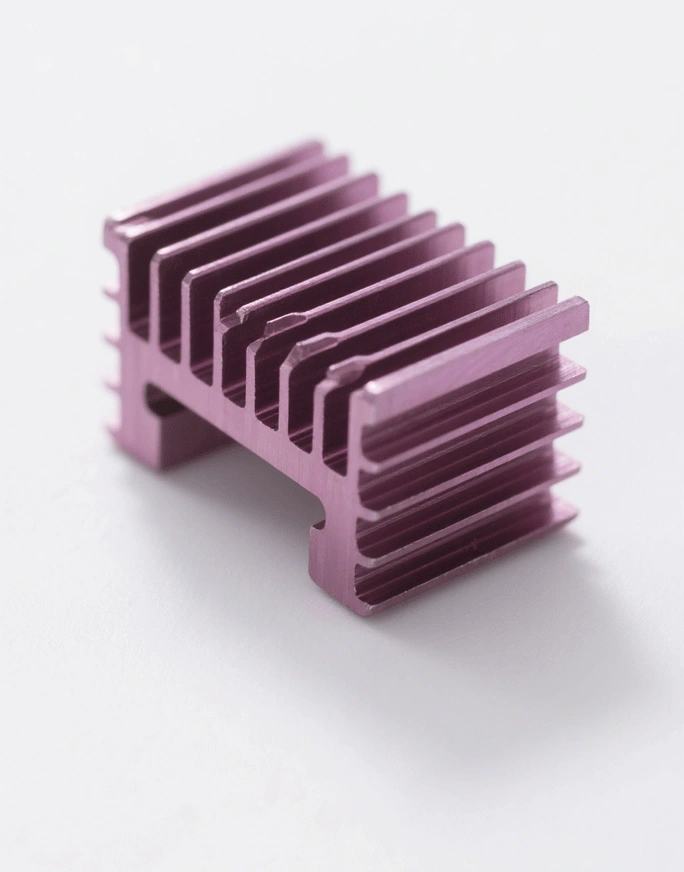

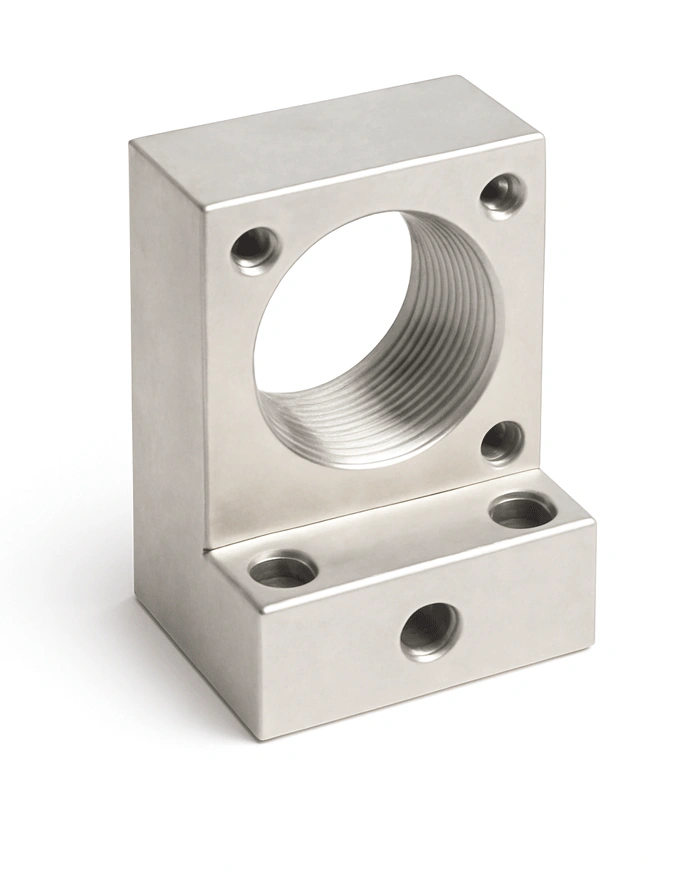

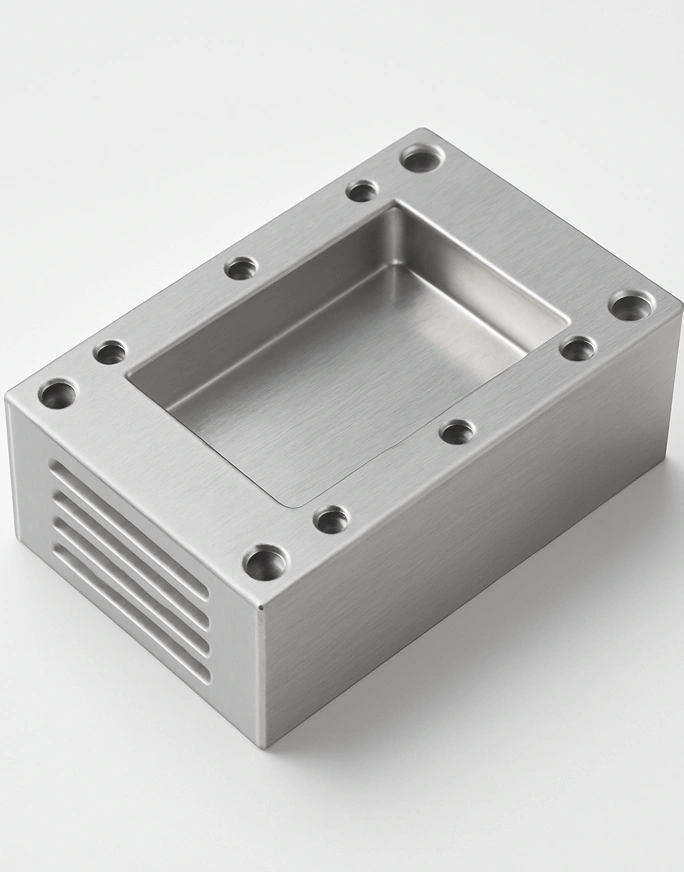

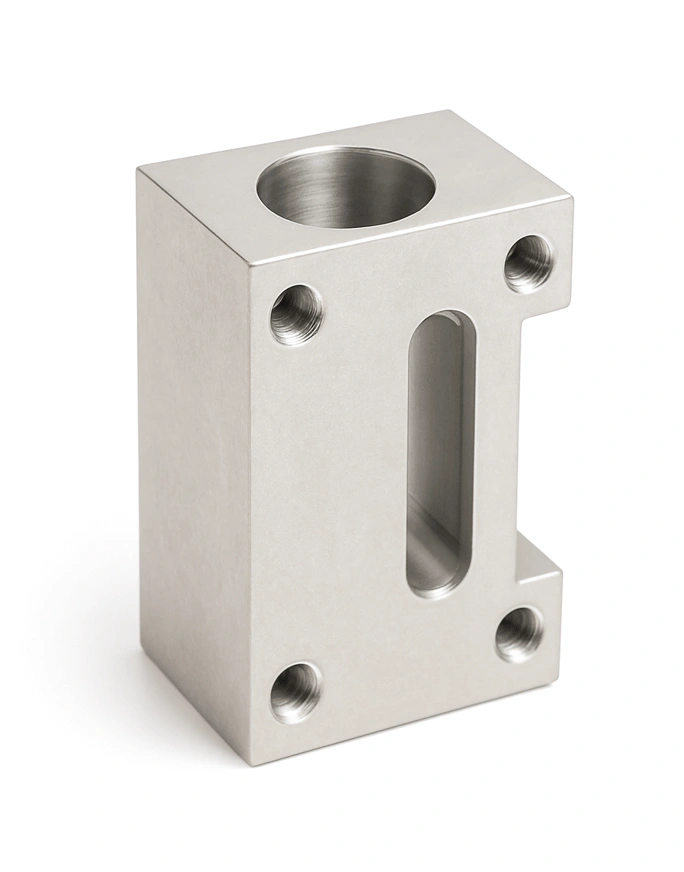

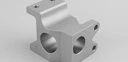

Our Latest Precision Machining Products We have Manufactured

Our ultra-precision components meet strict tolerances, ensuring reliable performance and consistent quality.

Precision Machining Tolerance

| Part Type | Tolerance Range |

|---|---|

| Metals (Aluminum, Stainless Steel, Brass, Copper Alloys) | ±0.01 mm |

| Engineering Plastics (ABS, POM, Nylon, PEEK, PTFE) | ±0.01 mm – ±0.02 mm |

| High-Performance Plastics (PEEK, PPSU, PTFE) | ±0.01 mm – ±0.03 mm |

| Large or Complex Components (>500 mm) | ±0.02 mm – ±0.05 mm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Precision Machining Materials

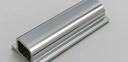

Aluminum alloys

Aluminum is lightweight, corrosion-resistant, and highly machinable, making it an excellent choice for precision machining. It provides a strong balance of durability and surface finish while maintaining a high strength-to-weight ratio. Aluminum parts are widely used in aerospace housings, automotive brackets, electronic enclosures, and medical instruments where both precision and performance are required.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, anodized, bead blasted, polished

Stainless steel

Stainless steel offers outstanding corrosion resistance, toughness, and long-term durability, making it suitable for precision-machined parts that must perform under demanding conditions. It is commonly used in medical implants, surgical devices, food-grade processing equipment, automotive components, and aerospace fasteners where hygiene and strength are critical.

- Mill Lead Time: As fast as 5 days

- Finishes: Passivated, polished, bead blasted, electropolished

Tool Steel

Tool steels are valued for their superior hardness, wear resistance, and heat resistance, making them ideal for precision tooling and mold-making. They are often used to manufacture dies, stamping tools, cutting inserts, and industrial mold components for aerospace, automotive, and heavy-duty machinery industries where durability and accuracy are essential.

- Mill Lead Time: As fast as 7 days

- Finishes: Heat-treated, polished, ground

Carbon steel

Carbon steel is versatile, cost-effective, and provides excellent strength and toughness, making it suitable for precision machining of structural and mechanical components. It is widely used in shafts, gears, fasteners, and machine parts for automotive, construction, and general industrial applications, where reliability and mechanical performance are important.

- Mill Lead Time: As fast as 5 days

- Finishes: Black oxide, zinc plated, polished

Brass & Bronze

Brass and bronze are easy to machine, resistant to corrosion, and have good strength and conductivity, making them ideal for precision fittings, bushings, and decorative parts. These materials are widely used in plumbing fixtures, aerospace connectors, electronic components, and architectural hardware where machinability and surface aesthetics are highly valued.

- Mill Lead Time: As fast as 3 days

- Finishes: Polished, nickel plated, sandblasted

Copper

Copper provides excellent electrical and thermal conductivity, making it an essential choice for precision-machined electronic and heat management components. It is commonly used in heat exchangers, electrical contacts, conductive terminals, and telecommunication parts, where efficiency and accuracy are critical for performance in demanding industrial environments.

- Mill Lead Time: As fast as 4 days

- Finishes: Polished, nickel plated, tin coated

Titanium Alloys

Titanium combines exceptional strength, corrosion resistance, and lightweight properties, making it highly suitable for high-performance precision machining applications. It is frequently used in aerospace turbine components, aircraft structures, orthopedic implants, and racing parts where both biocompatibility and structural reliability are crucial.

- Mill Lead Time: As fast as 7 days

- Finishes: Polished, anodized, bead blasted

Magnesium Alloys

Magnesium is the lightest structural metal and offers excellent machinability with a superior strength-to-weight ratio. It is widely applied in aerospace housings, automotive lightweight parts, and electronic casings where weight reduction without sacrificing strength is essential, helping manufacturers improve efficiency and performance in critical designs.

- Mill Lead Time: As fast as 4 days

- Finishes: Anodized, chromate plated, polished

ABS

ABS is tough, impact-resistant, and easy to machine, making it ideal for prototypes and functional plastic components. Its stability and low processing cost make it suitable for automotive dashboards, electronic housings, appliance parts, and consumer products where strength and accuracy are required.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, painted, polished, textured

PC

Polycarbonate offers excellent impact resistance, optical clarity, and dimensional stability, making it perfect for precision machining. It is often used in protective covers, transparent housings, lenses, and medical device components that require durability with high visual quality.

- Mill Lead Time: As fast as 3 days

- Finishes: Polished, vapor polished, clear-coated

PMMA

Acrylic provides excellent optical transparency and is easy to machine, making it suitable for parts requiring both clarity and aesthetics. It is commonly applied in light guides, display covers, signage, and optical instrument components where polished finishes and precision are essential.

- Mill Lead Time: As fast as 3 days

- Finishes: Polished, vapor polished, UV-coated

POM

Acetal is highly machinable, dimensionally stable, and provides low friction, making it excellent for precision machining of functional parts. It is widely used in gears, conveyor rollers, pump components, and automotive mechanical parts where durability and low wear are important.

- Mill Lead Time: As fast as 4 days

- Finishes: Raw, polished, dyed

Nylon (PA6, PA66)

Nylon is strong, wear-resistant, and offers self-lubricating properties, making it well-suited for moving and load-bearing parts. It is frequently used in gears, bushings, bearings, and industrial mechanical components where toughness and long-term performance are required.

- Mill Lead Time: As fast as 4 days

- Finishes: Raw, polished, dyed

PVC (Polyvinyl Chloride)

PVC is cost-effective, lightweight, and offers excellent chemical and corrosion resistance, making it suitable for precision machining of fittings, valves, and enclosures. It is often used in industrial fluid handling, electrical insulation, and protective housings.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, polished, painted

HDPE (High-Density Polyethylene)

HDPE is lightweight, impact-resistant, and easy to machine, with strong chemical resistance. It is often applied in food processing equipment, fluid containers, outdoor enclosures, and packaging components where durability and hygiene are critical.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, polished, textured

PEEK

PEEK combines excellent mechanical strength, chemical resistance, and heat stability, making it one of the most advanced plastics for precision machining. It is widely used in aerospace brackets, medical implants, semiconductor equipment, and high-performance automotive parts where both durability and biocompatibility are required.

- Mill Lead Time: As fast as 5 days

- Finishes: Raw, polished, machined textured

PTFE (Teflon)

PTFE is non-stick, chemically inert, and has one of the lowest friction coefficients, making it ideal for precision seals, gaskets, valve seats, and insulators. It is widely used in chemical processing, food-grade equipment, and electronics where high purity and wear resistance are essential.

Mill Lead Time: As fast as 4 days

Finishes: Raw, polished, machined textured

PEI (Ultem)

PEI combines high strength, flame resistance, and dimensional stability, making it suitable for precision parts in aerospace, electronics, and medical devices. It is commonly used in electrical connectors, sterilizable surgical components, and high-heat housings where reliability under stress is critical.

- Mill Lead Time: As fast as 5 days

- Finishes: Raw, polished, dyed

PPSU (Polyphenylsulfone)

PPSU offers outstanding impact resistance, hydrolytic stability, and sterilization tolerance, making it ideal for precision machining in demanding environments. It is often used in reusable medical instruments, fluid handling systems, and aircraft interior components requiring strength and heat resistance.

Mill Lead Time: As fast as 5 days

Finishes: Raw, polished, machined textured

PPS (Polyphenylene Sulfide)

PPS is known for its high thermal stability, chemical resistance, and rigidity, making it suitable for precision-machined parts in automotive, electronics, and aerospace sectors. Typical applications include pump components, electrical connectors, and engine parts exposed to high temperatures.

Mill Lead Time: As fast as 4 days

Finishes: Raw, polished, machined textured

Glass-Filled Nylon / Reinforced Composites

Glass-filled nylon significantly improves stiffness, strength, and dimensional stability compared to standard nylon, making it suitable for structural precision parts. It is commonly used in automotive housings, gears, industrial equipment brackets, and aerospace applications where lightweight yet durable performance is needed.

Mill Lead Time: As fast as 5 days

Finishes: Raw, polished, machined textured

Finishing Options for Precision Machining

| Name | Description | Can Be Applied with |

|---|---|---|

Chem Film / Anodizing (Type I, II, III)

Chem Film / Anodizing (Type I, II, III)

|

Improves corrosion resistance and surface hardness, commonly used for aluminum alloys. | Aircraft frames, wing structures, engine parts, landing gear components |

Passivation

Passivation

|

Enhances corrosion resistance by removing free iron and creating a protective oxide layer. | Aircraft engine parts, structural components, fasteners |

Bead Blasted Finish

Bead Blasted Finish

|

Creates a uniform matte or satin texture for improved aesthetics and surface uniformity. | Aluminum housings, titanium covers, stainless steel enclosures |

Electropolishing

Electropolishing

|

Polishes metal parts to improve smoothness, reduce friction, and enhance corrosion resistance. | Stainless steel parts in medical devices, aerospace turbine blades |

Powder Coating

Powder Coating

|

Provides a durable coating that offers protection against wear, chemicals, and environmental factors. | Aircraft exterior panels, engine components, industrial machine housings |

Nickel Plating (Electroless / Electroplated)

Nickel Plating (Electroless / Electroplated)

|

Adds a layer of nickel to improve surface hardness, corrosion resistance, and wear resistance. | Aerospace engine components, valve seats, mechanical brackets |

Zinc Plating

Zinc Plating

|

Cost-effective corrosion protection, provides a shiny finish. | Automotive fasteners, steel shafts, mechanical components |

Black Oxide

Black Oxide

|

Creates a dark matte finish with mild corrosion resistance. | Custom ColorsPrecision steel tools, gears, machine parts |

Polishing / Mirror Finish

Polishing / Mirror Finish

|

Achieves smooth or reflective surfaces for cosmetic or functional needs. | Medical instruments, consumer electronics housings, decorative components |

Painting / Spray Coating

Painting / Spray Coating

|

Adds protective color layers, improves aesthetics and branding. | Metal casings, plastic enclosures, industrial and consumer product housings |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Precision Machining Design Guide

In this guide to precision machining, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

Precision Machining Service FAQs

What is your typical lead time for precision machining orders?

Prototypes can be delivered in as fast as 3–5 days, while batch production usually takes 1–2 weeks depending on complexity and volume.

What materials can you machine?

We work with a wide range of metals (aluminum, stainless steel, titanium, copper, brass, steel) and plastics (ABS, POM, PC, PEEK, PTFE, etc.).

What tolerances can you achieve?

We can hold tolerances down to ±0.005 mm for metals and ±0.01 mm for plastics, verified with CMM and optical inspection.

Do you provide surface finishing?

es, we offer anodizing, plating, bead blasting, powder coating, polishing, and more, depending on your design needs.

Can you handle both prototypes and mass production?

Absolutely. We specialize in rapid prototyping, small-batch machining, and full-scale production with consistent quality.

How do you ensure part quality?

Every part goes through strict dimensional checks, including CMM inspection and visual QC, to meet design specifications.

Can you provide DFM feedback before production?

Yes, our engineers review every design and give manufacturability feedback to save time and reduce costly revisions.

Do you ship internationally?

Yes, we regularly ship machined parts worldwide using DHL, FedEx, UPS, or sea freight based on customer preference.

Are You Looking for Precision Machining Manufacturer in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.