Prototypes Injection Molding Services

Robotika delivers prototype injection molding services, offering fast lead times, precise low-volume runs, and reliable part quality for early testing and validation.

- Tolerances controlled as tight as ±0.05 mm

- Able to prototype injection molding parts 10,000+ per month

- Standard injection molding lead time 7-15 days

- Support low-volume production, material versatility, and rapid turnaround

Start a New Prototypes Injection Molding Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable Prototypes Injection Molding Supplier from China

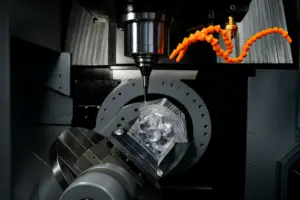

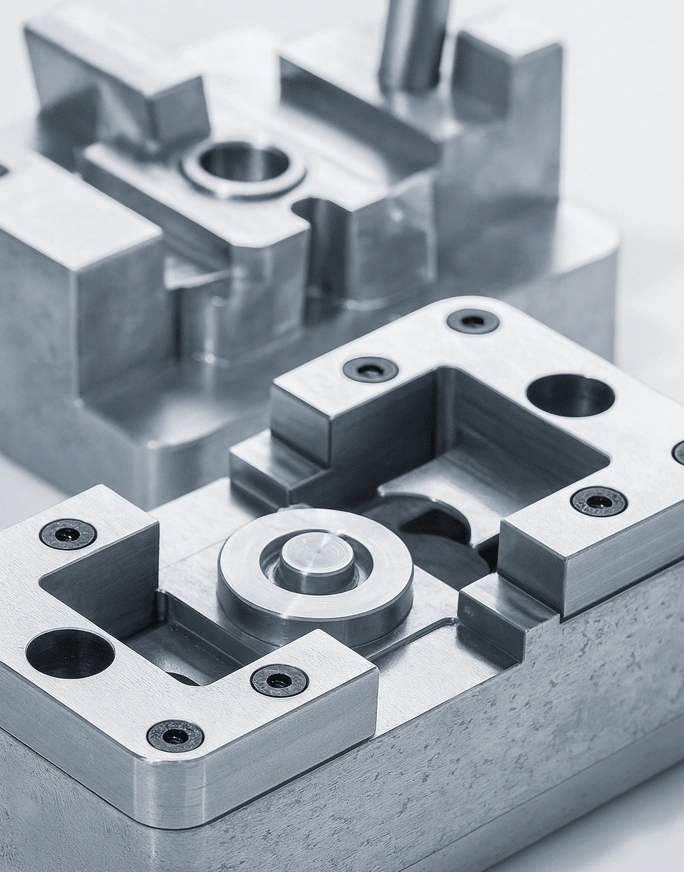

Robotika is a professional Prototypes Injection Molding manufacturer in China. With over 10 years of industry manufacturing experience, Robotika produces thousands of prototype and low-volume molded parts annually for global clients. Our prototype injection molding services are designed to help customers accelerate product development and reduce costs in early-stage manufacturing. By combining CNC-machined tooling with rapid molding techniques, we provide functional prototypes and small-batch production that closely match final products in material, strength, and surface quality. This allows clients to validate designs, perform functional testing, and prepare for full-scale production with confidence.

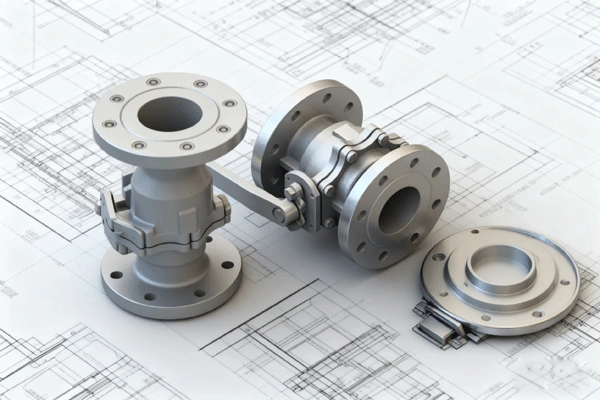

Our services support a wide range of industries, including automotive, medical devices, aerospace, electronics, and industrial equipment. By integrating precision machining with rapid molding solutions, we deliver stable supply, flexible capacity, and reliable support for businesses worldwide.

Our Prototypes Injection Molding Capabilities

Robotika’s prototype injection molding services combine CNC-machined tooling, low-volume production, material versatility, and rapid turnaround to support customers in accelerating product development. We work with a wide range of plastics and engineering resins, including ABS, PC, PP, nylon, and PEEK. We offer multiple surface finishing options such as polishing, texturing, painting, and bead blasting, allowing prototypes to meet both functional and aesthetic requirements. With CNC precision mold making, our processes can achieve tolerances as tight as ±0.02 mm for plastic parts, ensuring high dimensional accuracy and repeatability. Every part undergoes strict quality inspection to guarantee consistency and performance for demanding industries.

Prototypes Injection Molding Capabilities

Maximum Build Size

We can manufacture parts as large as 800mm × 500mm × 300mm, suitable for most prototype needs

Material Compatibility

We support general injection molding material like ABS, PP, PC, Nylon, POM, PEEK, and more, addressing diverse prototyping requirements.

Molding Precision

Our standard tolerance is controlled within ±0.05mm, ideal for functional prototypes and small batch production in small numbers.

Surface Finishing Options

We provide texturing, polishing, painting, pad printing, laser engraving, and other finishing methods for better aesthetics and functionality.

Delivery Time

Our standard injection molding lead time is 7-15 days, with expedited services available for urgent projects.

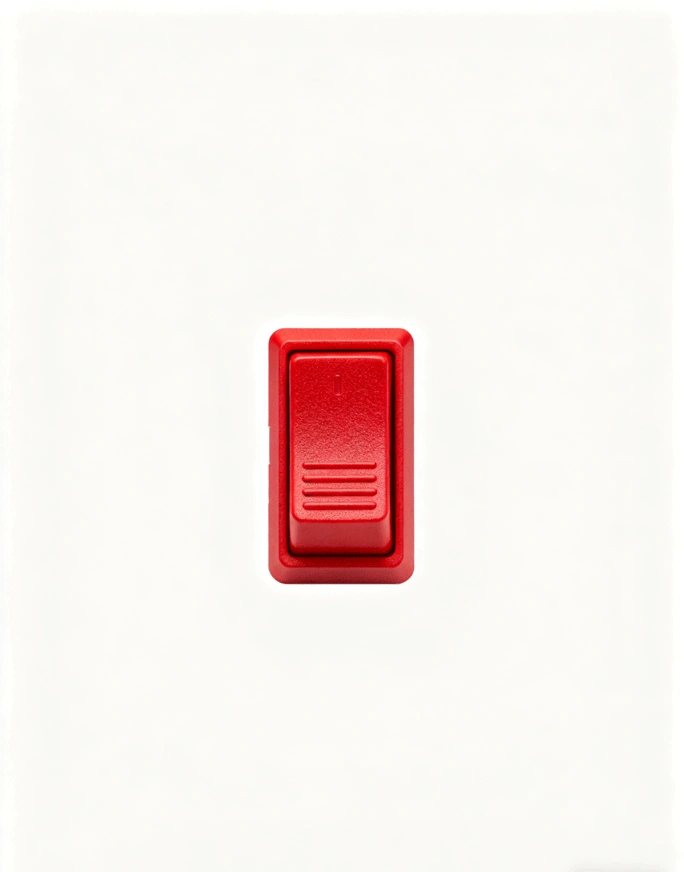

Our Latest Prototypes Injection Molding Products We have Manufactured

Our production-grade plastic parts molded for functional testing, design validation, and smooth transition to mass production.

Prototypes Injection Molding Tolerance

| Part Type | Tolerance Range |

|---|---|

| Linear Dimensions | ±0.05 – ±0.10 mm |

| Small Features (<100 mm) | ±0.02 – ±0.05 mm |

| Large Features (>100 mm) | ±0.10 – ±0.20 mm |

| Hole Diameters | ±0.05 – ±0.10 mm |

| Wall Thickness | ±0.05 – ±0.10 mm |

| Flatness/Parallelism | ±0.05 – ±0.15 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm |

- *Robotika accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Prototypes Injection Molding Materials

ABS

ABS is one of the most widely used materials for prototype injection molding due to its excellent toughness, impact resistance, and dimensional stability. It is easy to mold and finish, making it ideal for functional prototypes and appearance models. ABS is commonly used in automotive interior components, electronic housings, and home appliance parts. For example, dashboards, remote control shells, and computer cases are often prototyped with ABS to validate both function and aesthetics.

Mill Lead Time: As fast as 3 days

Finishes: Raw, painted, plated, textured

PP (Polypropylene)

Polypropylene is a lightweight, chemically resistant material ideal for prototype injection molding of consumer products and packaging. It provides excellent flexibility, fatigue resistance, and moisture resistance, making it suitable for hinges, caps, and containers. PP prototypes are often used in automotive trims, medical packaging, and household goods, where toughness and chemical resistance are required. For example, prototype bottle caps or storage boxes are frequently made from PP to simulate end-use conditions.

Mill Lead Time: 3–5 days

Finishes: Raw, textured, polished

PE (Polyethylene)

Polyethylene is a versatile thermoplastic for prototype injection molding thanks to its toughness, flexibility, and impact resistance. It is widely used in consumer goods, packaging, and industrial applications where durability is essential. PE prototypes are commonly applied in containers, protective cases, and tubing. For instance, industrial storage bins or prototype protective covers are often made with PE to test strength and resilience before production.

Mill Lead Time: 3–5 days

Finishes: Raw, polished, textured

PC (Polycarbonate)

Polycarbonate is an excellent choice for prototype injection molding where clarity, toughness, and heat resistance are required. It offers high optical transparency and excellent impact strength, making it suitable for lighting covers, lenses, and electronic housings. PC prototypes are widely used in automotive lighting, consumer electronics, and safety equipment. For example, headlamp covers and safety goggles are frequently prototyped in PC to evaluate optical performance and durability.

Mill Lead Time: 4–6 days

Finishes: Raw, polished, painted, UV-coated

PS (Polystyrene)

Polystyrene is a cost-effective material for prototype injection molding, offering ease of processing and good dimensional stability. It is suitable for non-structural prototypes where visual validation and lightweight design are priorities. PS prototypes are often used in packaging, disposable products, and lightweight consumer goods. For example, prototype trays, cosmetic containers, and display items are commonly molded in PS to verify appearance and fit.

Mill Lead Time: 3–4 days

Finishes: Raw, polished, painted

Nylon (PA, PA66 with GF)

Nylon is a popular choice for prototype injection molding due to its excellent strength, wear resistance, and toughness. When reinforced with glass fiber, it offers even greater stiffness and dimensional stability. Nylon prototypes are widely used in gears, mechanical housings, and automotive under-the-hood components, where durability and fatigue resistance are critical. For example, gear wheels and bearing housings are often prototyped with Nylon to test mechanical performance.

Mill Lead Time: 4–6 days

Finishes: Raw, polished, painted

PEEK (Polyether Ether Ketone)

PEEK is a high-performance thermoplastic known for its outstanding heat resistance, chemical resistance, and mechanical strength. It is suitable for prototype injection molding of aerospace, medical, and industrial components that must withstand extreme conditions. PEEK prototypes are commonly used in surgical instrument handles, aerospace brackets, and semiconductor parts. For instance, a prototype implantable device housing may be molded in PEEK for biocompatibility and strength validation.

Mill Lead Time: 7–10 days

Finishes: Raw, polished, machined

PPS (Polyphenylene Sulfide)

PPS is ideal for prototype injection molding where high dimensional stability, chemical resistance, and flame retardancy are required. It performs well under high temperatures and harsh environments, making it suitable for automotive, electrical, and industrial applications. PPS prototypes are often used in connectors, pump housings, and electronic components. For example, automotive electrical connectors are prototyped with PPS to test heat and chemical resistance in real conditions.

Mill Lead Time: 6–8 days

Finishes: Raw, polished, coated

POM (Polyoxymethylene/Acetal/Delrin)

POM is valued in prototype injection molding for its excellent stiffness, low friction, and dimensional accuracy. It is particularly suited for functional prototypes requiring smooth movement and wear resistance. POM prototypes are widely used in gears, fasteners, and precision mechanical components. For instance, snap-fit housings or gear assemblies are commonly prototyped with POM to validate assembly performance and tolerance control.

Mill Lead Time: 4–6 days

Finishes: Raw, polished, painted

PSU / PES (Polysulfone Family)

PSU and PES are high-performance plastics offering excellent heat resistance, hydrolytic stability, and transparency. They are ideal for prototype injection molding of medical, laboratory, and electronic applications. PSU/PES prototypes are often used in sterilizable medical components, filter housings, and electronic casings. For example, transparent sterilization trays and medical connectors are frequently molded in PSU/PES to test strength and high-temperature performance.

Mill Lead Time: 6–9 days

Finishes: Raw, polished, transparent finish

Finishing Options for Prototypes Injection Molding

| Name | Description | Can Be Applied with | Applicable Materials |

|---|---|---|---|

Polishing

Polishing

|

Creates a smooth, glossy surface for improved appearance and optical clarity. | Manual polishing, CNC polishing | ABS, PC, PMMA, PEEK, Aluminum molds |

Texturing (Etching/Grain)

Texturing (Etching/Grain)

|

Adds matte or patterned textures on part surfaces, often via chemical etching. | Mold surface treatment | ABS, PP, PE, PC, Nylon |

Painting / Spray Coating

Painting / Spray Coating

|

Adds color, UV resistance, or protective coatings to prototypes. | Manual spray or automated system | ABS, PC, PS, Nylon, PEEK |

Plating (Chrome / Nickel)

Plating (Chrome / Nickel)

|

Provides decorative or functional metallic coating for aesthetics and conductivity. | Electroplating / vacuum plating | ABS, PC, POM, Metal inserts |

Bead Blasting

Bead Blasting

|

Creates a uniform matte finish by blasting fine media onto the surface. | Sandblasting / bead blasting | ABS, Nylon, PC, Aluminum molds |

Anodizing

Anodizing

|

Forms a corrosion-resistant oxide layer with optional coloring (for metal molds). | Electrochemical process | Aluminum, Magnesium |

Laser Engraving

Laser Engraving

|

Permanent marking or logos directly on parts or molds. | CNC laser engraving | ABS, PC, Nylon, Aluminum, Steel |

Powder Coating

Powder Coating

|

Durable coating with color and texture options for improved wear resistance. | Electrostatic spraying | Metal prototypes, Aluminum, Steel molds |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Prototypes Injection Molding Design Guide

In this guide to prototype injection molding, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

Prototypes Injection Molding Service FAQs

What’s the minimum order quantity (MOQ) for prototype injection molding?

We don’t have a strict MOQ. Most projects start from as low as 1–50 parts depending on the design.

How fast can I get my prototype parts?

Lead time is usually 7–10 days for prototypes, and as fast as 3–5 days if the design is simple.

Can I use the same prototype mold for small-batch production?

Yes, our CNC-machined molds are durable enough for low-volume runs before moving to mass production.

What file formats do you accept for quotation?

We accept STEP, IGES, STL, and other common CAD files. Just send us your 3D model for review.

Do you provide surface finishing for prototypes?

Yes, we offer polishing, texturing, painting, plating, and other finishes to match your end-use requirements.

How do you ensure quality for prototype parts?

All parts are inspected with precision tools, and critical dimensions are verified using CMM if required.

Can you handle both plastic and metal prototypes?

Yes, we support a wide range of plastics and engineering resins, plus metal inserts if needed.

Are You Looking for Prototypes Injection Molding Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.