Rapid Tooling Service

Robotika provides rapid tooling services that support fast prototype molds and low-volume production tooling. Delivery within 7 days at the fastest.

- Lower development costs

- Development cycle can be shortened to 5-10 days

- Suitable for small-batch production and prototype development

- Enables frequent design changes and rapid iteration

- Supports personalized production

Start a New Rapid Tooling Project!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable Rapid Tooling Service Provider from China

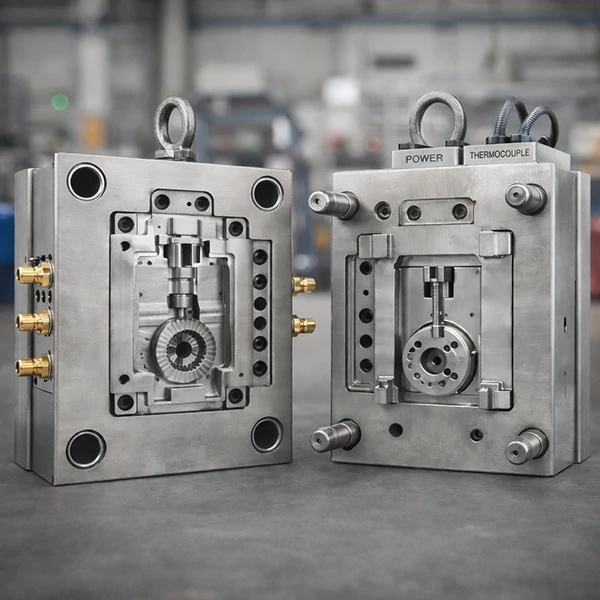

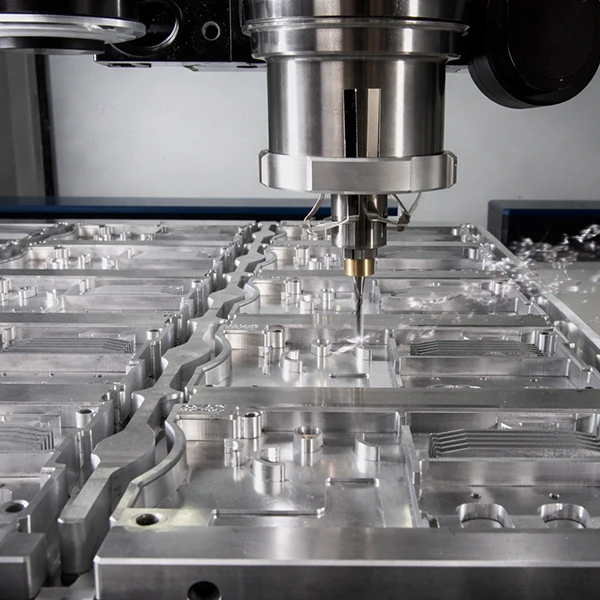

Robotika is a Chinese manufacturer of rapid tooling, which offers rapid tooling solutions between product development and production. Having the capability of highly developed CNC milling, turning, EDM, we are able to produce prototype molds, soft molds, and transitional molds to allow injection molding of plastics with high precision and accuracy. We possess internal machining capabilities and the expertise of our mold engineers to help us effectively serve the design verification, small-batch trials, and low-volume production.

Compared to traditional tooling, Robotika’s rapid tooling services can increase production speed by 1.5 times and reduce tooling costs and development risks. With over 10 years of CNC machining experience, Robotika supports rapid tooling projects for industries such as automotive, electronics, medical, industrial equipment, and consumer goods. We provide a stable supply of molds and fast-response engineering support. Supported by rigorous inspection standards and a manufacturing-oriented workflow, Robotika helps customers confidently transition from the prototyping stage to mass production.

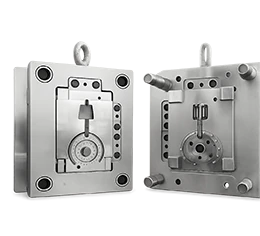

Our Rapid Tooling Capabilities

Robotika’s rapid tooling capabilities cover prototype molds, soft tooling, and bridge tooling, designed to support fast validation and low-volume injection molding. We deal with standard fast tooling material like aluminum alloy and pre-hardened tool steel and have a versatile trade off between tooling price, lead time, and mold durability. Such a choice of material enables our rapid tooling to satisfy the functional test, pilot production, and short-run production requirements. In order to maintain consistent molding performance and uniform quality of the part, Robotika provides a variety of surface finishing procedures to the rapid tooling components such as fine machining finishes, polishing and sandblasting to suit the mold durability and part release conditions. Our CNC machining processes for rapid tooling typically achieve tolerances of ±0.01 mm, with tighter control applied to critical mold areas such as shut-offs, core inserts, and parting lines when required.

Rapid Tooling Capabilities

Stage

Prototyping, low-volume batches, market testing

Mold Cost

1,000−20,000

Lead Time

5-10 days

Mold Lifespan

100-10,000 cycles

Design Flexibility

High (easy gate/cooling adjustments)

Tooling Materials

Aluminum alloys, pre-hardened tool steels

Tolerance

±0.01 mm

Typical Part Volume

Hundreds to low thousands of parts

Rapid Tooling Design Guide

In this guide to rapid tooling, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

Our Rapid Tooling Capabilities

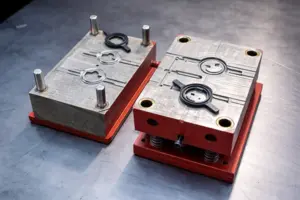

Prototype Molds

We use prototype molds to quickly validate part design, fit, and function without committing to production tooling, ideal for early development where speed, flexibility, and cost control matter most.

Prototypes molds are simpler structures and have shorter lead times compared to production molds that enable quick iteration and redesign. Although there is a restricted range of mold life, they provide dependable performance of molding with functional testing and preliminary check with plastic material of production grade.

- CNC Milling — Precision machining of mold cores, cavities, and inserts

- CNC Turning — Machining of round mold components and alignment features

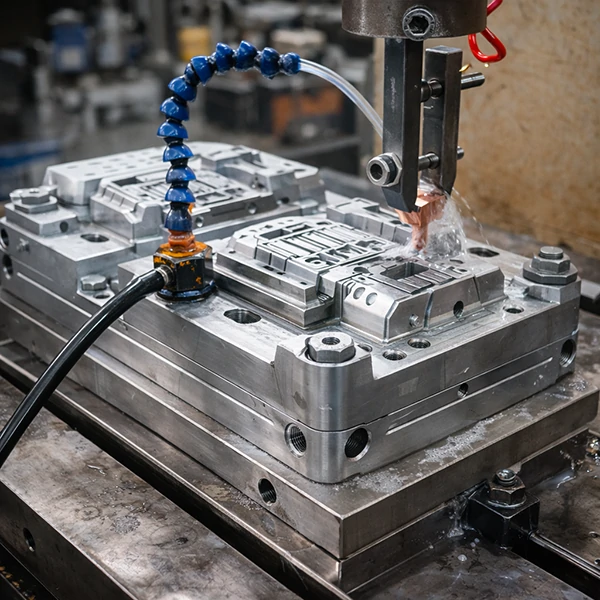

- CNC EDM — Deep cavities, sharp corners, and complex mold geometries

- Wire-Cut EDM — Accurate cutting of inserts, parting lines, and shut-off areas

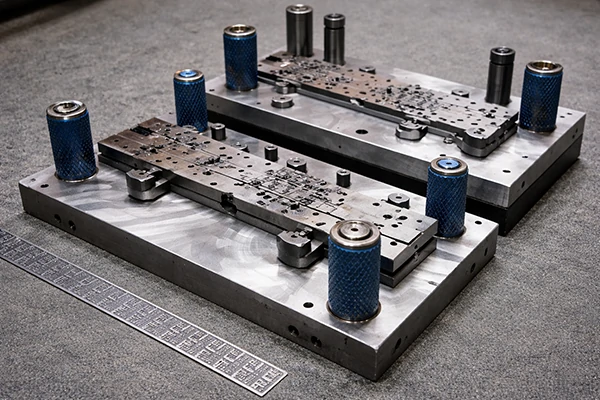

Injection Mold Making

We provide injection mold making services to support reliable plastic part production, covering prototype, pre-production, and low-volume manufacturing requirements. Our molds are engineered for dimensional accuracy, stable molding performance, and consistent part quality across development stages.

Our injection molds are built with optimized structures, selected steels, and precise machining to ensure durability, repeatability, and efficient cycle performance. Each mold is manufactured through design review, DFM optimization, assembly, and testing to meet project-specific quality and production targets.

- CNC Milling — Precision machining of mold bases, cores, cavities, and inserts

- CNC Turning — Machining of cylindrical mold components, bushings, and alignment parts

- CNC EDM — Machining of deep cavities, fine details, and complex mold features

- Wire-Cut EDM — Accurate cutting of parting lines, inserts, sliders, and shut-off areas

Prototypes Injection Molding

We provide prototypes injection molding services to validate part design, material selection, and molding performance using prototype tooling, without the cost and lead time of full production molds. This approach is ideal for early-stage development where fast turnaround, design flexibility, and controlled cost are critical.

Prototype injection molds feature simplified structures and shorter lead times, enabling rapid iteration and design refinement. While mold life is limited, they deliver stable molding performance for functional testing, assembly evaluation, and preliminary production-grade material verification before scaling to higher-volume manufacturing.

- CNC Milling — Precision machining of prototype mold cores, cavities, and inserts

- CNC Turning — Machining of round mold components and alignment features

- CNC EDM — Deep cavities, sharp corners, and complex mold geometries

- Wire-Cut EDM — Accurate cutting of inserts, parting lines, and shut-off areas

Materials & Precision Machining

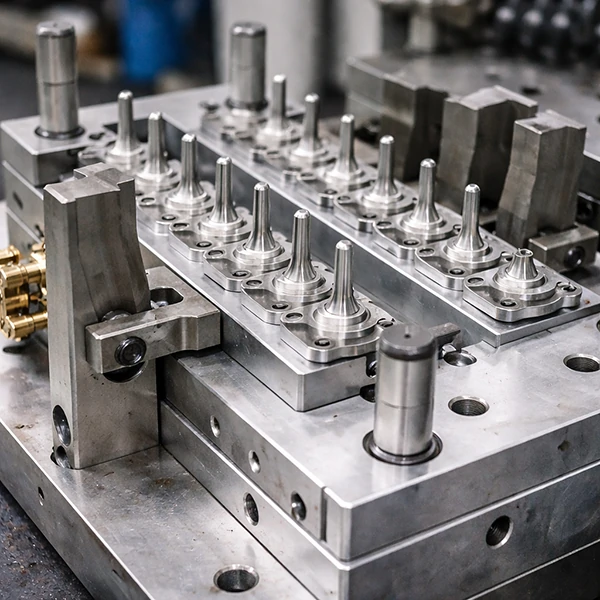

Our rapid tooling is produced with a well-chosen combination of aluminum alloys and pre-hardened tool steels to optimize the lead time, life, and the cost of the tooling. Selection of material is optimized depending on part geometry, anticipated production volume and molding performance requirements.

Accurate mold structures, close fit, and predictability in component positioning of the mold are guaranteed as a result of precision CNC machining. The important features of the molds are high repeatability machined to facilitate uniformity of part quality across the low-volume injection molding cycles.

- CNC Milling — High-precision machining of mold cavities, cores, and inserts

- CNC Turning — Round mold components, bushings, and alignment features

- CNC EDM — Fine details, deep pockets, and sharp internal geometries

- Wire-Cut EDM — Accurate parting lines, inserts, and shut-off surfaces

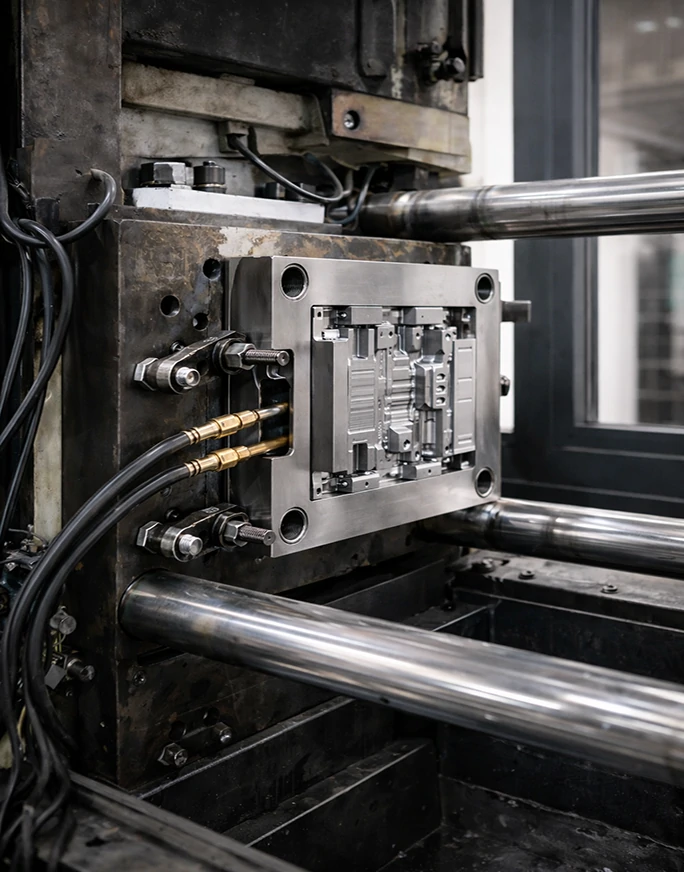

Rapid Tooling for Low-Volume Injection Molding

Our low-volume injection molding with rapid tooling enables fast production of end-use parts using tested, production-grade plastics, supporting part validation, pilot runs, and early market launch without the long lead times of hardened tooling.

Rapid tooling-based low-volume injection molding saves initial investment and risk of failure during development compared to traditional production molding and does not compromise the quality of parts. It enables manufacturers to test design, performance of the process and market reaction prior to the scaling to the full production.We are powered by advanced CNC machining and EDM processes. These rapid tooling projects support practical manufacturing across automotive, electronics, medical, and industrial applications. Each tool is engineered for functional validation, pilot production, and reliable low-volume injection molding, helping customers reduce risk and accelerate market entry.

- Injection Molding Setup — Optimized for short-run and pilot production

- Process Control — Stable molding parameters for consistent part quality

- Material Validation — Production-grade plastics for functional testing

- Rapid Transition — Seamless move from low-volume to mass production

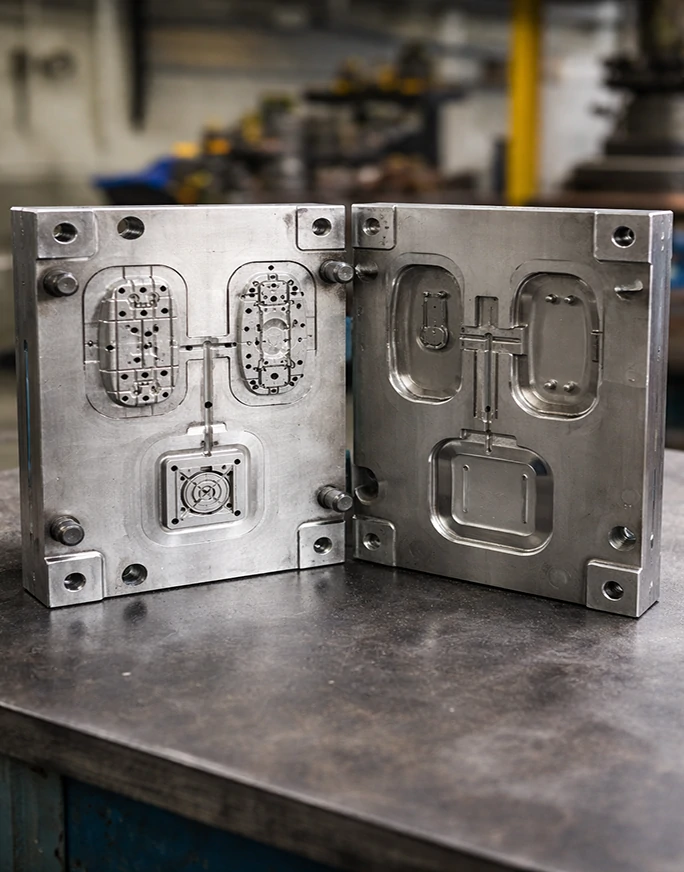

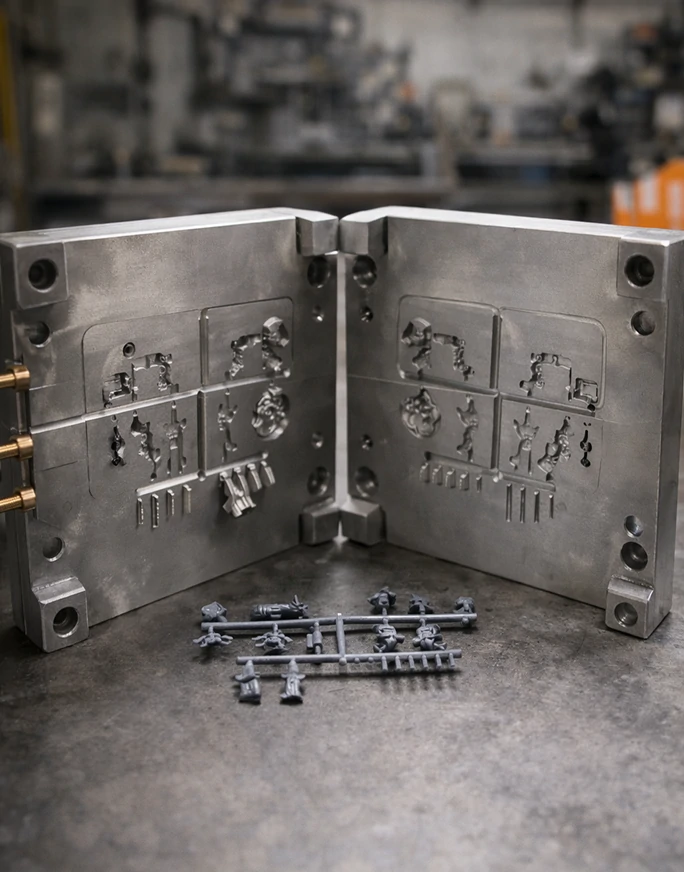

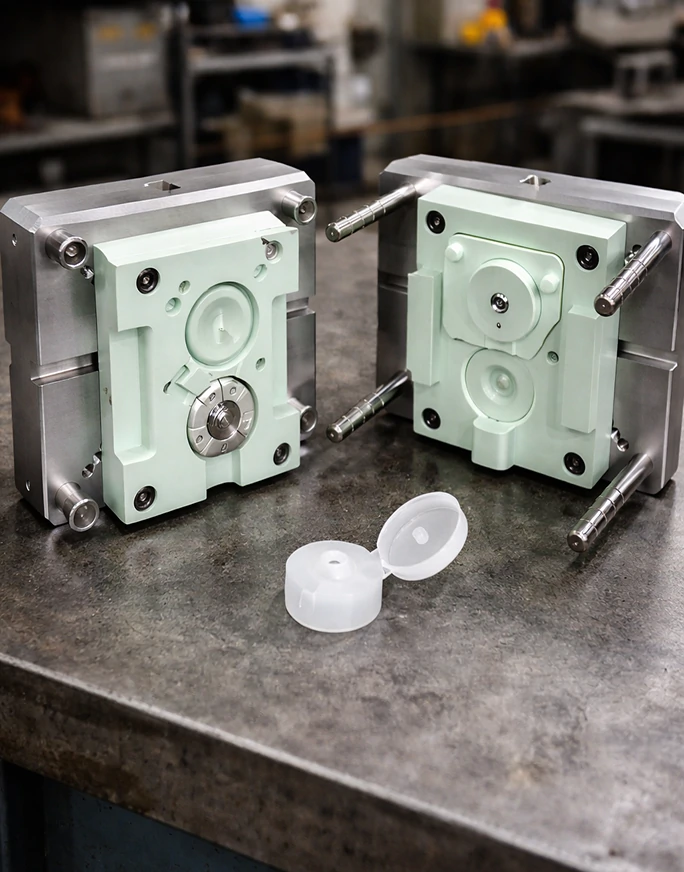

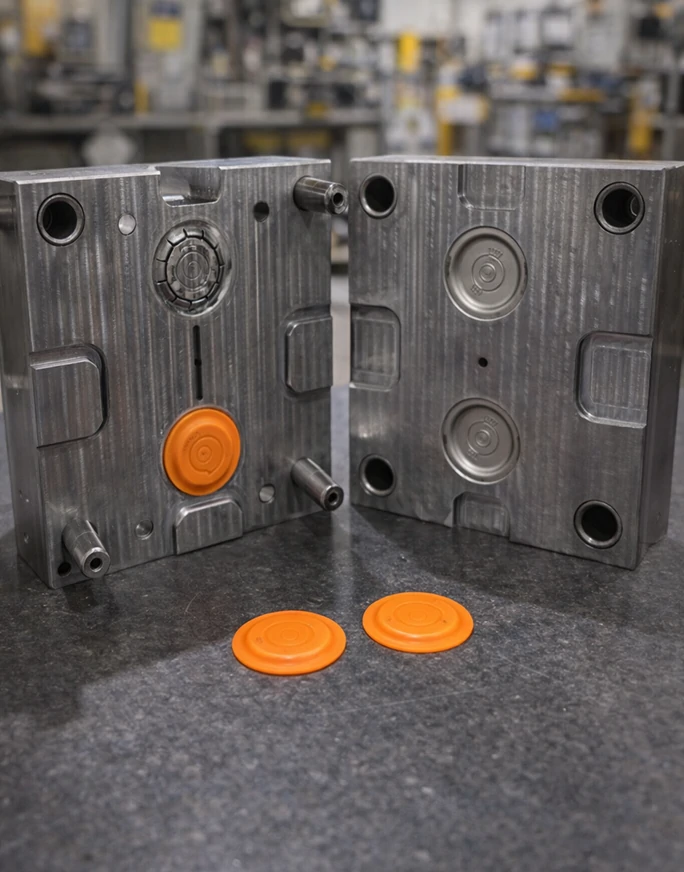

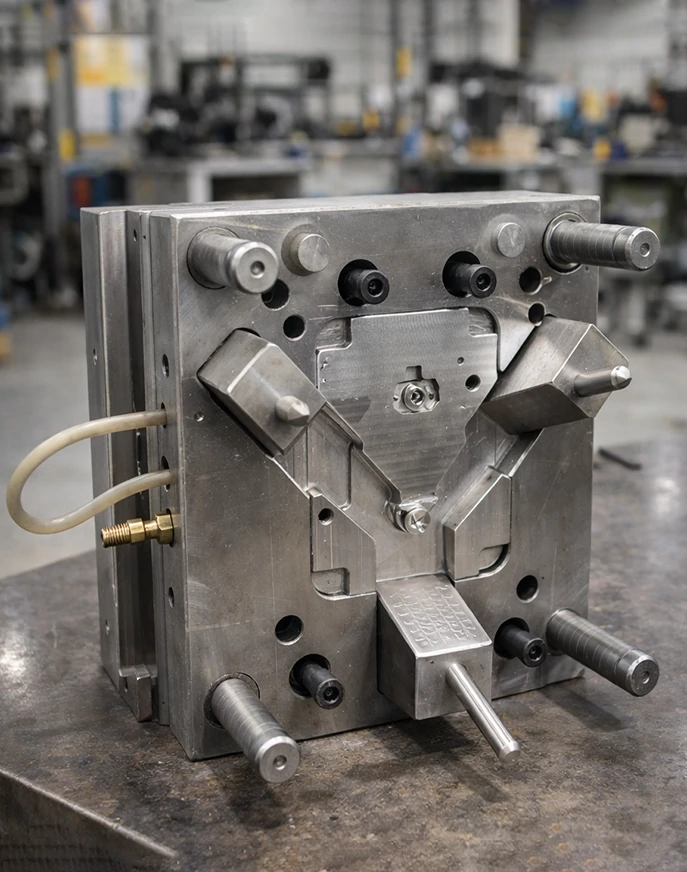

Our Latest Rapid Tooling Projects

Our machines are driven by the sophisticated CNC machining and EDM. These are fast tooling programs that are practical in manufacturing automotive, electronic, medical as well as industrial. All tools are designed to be functionally validated, pilot production, and have a dependable low-volume injection molding to assist customers mitigate the risk and quicken their market introduction.

Rapid Tooling Services FAQs

What is the lead time average of rapid tooling?

The majority of the rapid tooling projects are fully accomplished in 7-10 working days based on the complexity of the mold and the choice of materials.

What is the minimum order requirement?

Rapid tooling has no minimum order quantity. It is most suitable in prototyping, pilot run, and low volume production.

What is the number of parts that a fast tooling mold can make?

The average number of shots between 200 and several thousand is typical of the mold life based on the tooling material and the design of the part.

Is it possible to speed up tooling production on production grade materials?

Yes. Common plastics used in rapid tooling include ABS, PP, PC and engine grade.

Can it be redesigned once the design has been made?

Yes. Quick tooling enables quicker and more economical modification of design than hardened production molds.

What is the cost between rapid and production tooling?

When production is at the initial stage, rapid tooling is much cheaper, with a shorter lead time hence suitable.

Can rapid tooling transition to mass production later?

Absolutely. Rapid tooling is often used as a bridge to full production tooling, ensuring a smooth scale-up.

Are You Looking for Rapid Tooling Manufacturers in China?

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.