CNC Manufacturing for Robotics

Robotika provides high-quality CNC machining services for the robotics industry, with rapid prototype delivery in as fast as 7 days.

- 10+ years of CNC manufacturing experience in robotics

- Parts with tolerances as low as +/- 0.001 inches

- Advanced materials such as aluminum, titanium and composite materials are available

- 24/7 engineering support

Start Manufacturing Your Robotics Parts!

STEP | STP | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Reliable CNC Robotics Parts Supplier from China

Robotika provides CNC manufacturing services for the robotics industry, delivering precision-machined components with reliable accuracy and consistent quality. With strong prototyping and low- to medium-volume production capabilities, we help customers accelerate product development while ensuring parts such as housings, brackets, gears, and frames meet strict performance requirements. Our advantage lies in combining fast lead times, DFM analysis, and flexible material options to give robotics companies both design freedom and cost efficiency.

In addition, Robotika offers value-added services including material consultation, custom finishing for wear resistance and aesthetics, and rigorous dimensional inspection using automated CMM systems. With over 10 years of experience and more than 100,000 parts produced annually, we are trusted by industrial automation companies, service robot manufacturers, drone developers, and research institutions worldwide to deliver reliable CNC solutions for advanced robotics applications.

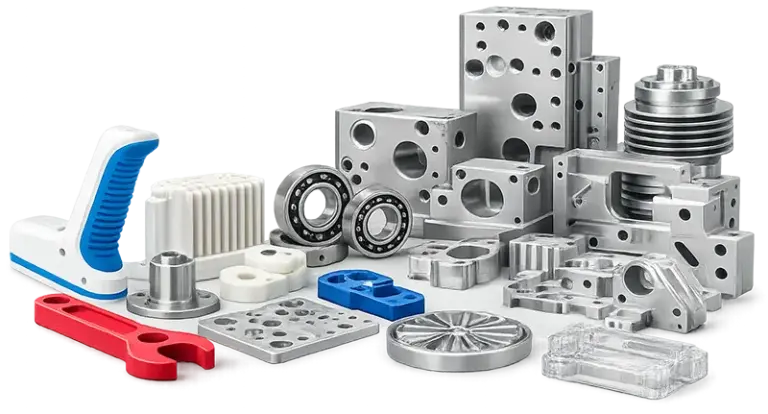

What kind of robotics parts can we make?

Robotika produces a wide range of CNC-machined components for the robotics industry, such as joint housings, gear brackets, actuator bases, end-effector fingers, cooling plates, and sensor enclosures. For load-bearing and structural parts, we typically machine aluminum alloys to ensure high strength while keeping weight low, and stainless steel for wear resistance in high-friction joints. Copper and brass are applied in conductive or heat-dissipating components like busbars and thermal plates, while engineering plastics such as PEEK and nylon are chosen for lightweight insulation, low noise, and smooth motion in sliding or guiding parts. To meet the functional and aesthetic demands of robotic systems, we provide finishes including anodizing for corrosion protection, bead blasting and brushing for improved surface texture, hard coating for wear resistance, and powder coating for durability.

- Joint housings

- Actuator bases

- Gear brackets

- Gearbox housings

- End-effector fingers

- Robotic arms and linkages

- Motor mounts

- Bearing seats

- Structural frames

- Cooling plates

- Heat sinks

- Sensor housings

- Camera mounts

- Gripper jaws

- Drive shafts

- Pulley wheels

- Guide rails

- Protective enclosures

- Control unit casings

- Cable clamps

- Spacer rings

- Mounting brackets

- Servo covers

- Lightweight aluminum panels

Robotics CNC Machining Capabilities

Supported Materials

We machine robotics-grade materials including aluminum alloys (6061, 7075), titanium (Ti-6Al-4V), stainless steel (304, 316L), and high-performance plastics like PEEK and PTFE, ideal for precise and durable robotics components.

Machining Accuracy

Our standard tolerances are maintained within ±0.01mm, ensuring reliable performance for structural and functional robotics parts.

Maximum Machining Size

Up to 1000mm × 600mm × 500mm to accommodate diverse robotics components.

Surface Finishing Options

Anodizing, polishing, bead blasting, powder coating, and more to enhance performance and durability.

Delivery Time

Our typical lead time: 5–10 days, with expedited options for urgent projects.

CNC Manufacturing for Robotics Workflow

Our precision-driven CNC manufacturing workflow built for robotics components, ensuring tight tolerances, assembly accuracy, and consistent quality.

Engineering Review & DFM

We review drawings and 3D models to evaluate tolerances, interfaces, motion requirements, and manufacturability, ensuring robotic components meet precision and assembly needs.

Precision CNC Machining

Using advanced multi-axis CNC machines, we manufacture robotic components from aluminum, steel, stainless steel, and engineering plastics with tight tolerances and consistent quality.

Prototype & Validation

Prototype or first article parts are produced for dimensional verification, assembly fitting, and motion validation before moving to volume production.

Inspection & Quality Control

All parts undergo in-process and final inspections, including dimensional and visual checks, to ensure repeatability, accuracy, and reliable robotic performance.

Packaging & Delivery

Components are cleaned, protected, and securely packaged to prevent damage during handling and transportation, ensuring safe delivery for robotic system integration.

Services that Meet Your Robotics CNC Manufacturing Needs

Our CNC manufacturing services support robotic components with high precision, assembly accuracy, and repeatability, from engineering review to production-ready delivery.

Drawing Review

We review drawings and 3D models to understand geometry tolerances interfaces motion requirements and functional constraints for robotic components applications.

Material Evaluation

We confirm material types and grades to ensure strength optimization durability wear resistance and long term performance for robotics applications.

Tolerance Evaluation

We analyze critical tolerances alignment points and mating dimensions to ensure precise motion control and repeatable assembly in robotics systems.

Manufacturability Review

We identify machining challenges and optimize designs to improve manufacturability reduce rework shorten lead times and support scalable robotics production.

Machining Strategy

We define machining strategies setups and sequences based on geometry materials and precision requirements for robotic component production consistency efficiency.

Tooling & Fixtures

We select appropriate tools and fixtures to ensure machining stability accuracy repeatability and surface quality during robotics component manufacturing processes.

Quality Planning

We establish inspection plans measurement methods and quality controls to maintain consistent performance across robotic component manufacturing processes operations projects.

Production Scheduling

We plan capacity resources and lead times to support stable supply on time delivery and scalable robotics manufacturing programs globally.

Prototype Machining

We produce prototype or first article parts to validate geometry tolerances and machining feasibility for robotic components before production approval.

Assembly Verification

We verify part fit alignment and interface accuracy to ensure smooth assembly and precise motion within robotic systems during integration.

Functional Evaluation

We support functional testing to confirm motion accuracy load performance and operational reliability for robotic applications under real world conditions.

Design Optimization

We provide engineering feedback to refine designs reduce iterations improve manufacturability and prepare robotics projects for production scale volume manufacturing.

Multi-Axis CNC Machining

We machine robotic components using advanced CNC equipment to achieve tight tolerances consistent accuracy and complex geometry control during production.

Material Processing

We process aluminum steel stainless steel and engineering plastics commonly used in robotic system manufacturing applications requiring precision durability consistency.

In-Process Inspection

We perform inspections during machining to detect deviations early maintain accuracy and ensure consistent robotic component quality across all batches.

Batch Production Control

We ensure stable processes repeatable quality and dimensional consistency across small to medium robotics production runs for long term supply.

Dimensional Inspection

We conduct final dimensional inspections using calibrated equipment to verify accuracy and tolerance compliance for robotic components before customer delivery.

Visual Inspection

We inspect surface finish edges and critical features to meet appearance durability and functional expectations for robotics equipment manufacturing standards.

Final Approval

We document inspection results to support traceability consistency and quality management for robotics component supply programs across global customer projects.

Quality Documentation

We approve parts for delivery only after all inspection results and quality requirements are fully satisfied by engineering teams internally.

Part Cleaning

We clean finished components to remove residues oils and contaminants before packaging for robotics manufacturing supply chain readiness and protection.

Protective Packaging

We apply protective packaging to prevent damage deformation or contamination during handling storage and transportation of robotics components worldwide safely.

Secure Packing

We pack components securely based on size weight and logistics requirements to ensure safe transit for robotics projects globally delivered.

On-Time Delivery

We arrange reliable logistics to ensure robotic components arrive on time supporting assembly schedules and production continuity for customer operations.

Total Robotics Project Success with 360° Robotika Approach

Precision for Robotic Motion

We deliver tight tolerances and consistent dimensional accuracy to ensure robotic components move smoothly, assemble precisely, and perform reliably in dynamic operating conditions.

Materials Optimized for Robotics

We machine aluminum, steel, stainless steel, and engineering plastics selected for strength, weight balance, wear resistance, and long-term robotic performance.

Engineering-Driven Manufacturing

Our engineering team supports DFM review, process planning, and rapid problem-solving to improve manufacturability, reduce iterations, and accelerate robotics project timelines.

Stable Supply and Scalable Production

From prototypes to repeat production, our controlled manufacturing processes ensure consistent quality, stable supply, and on-time delivery for robotics programs.

Robotics Parts We Have Manufactured

Explore a selection of robotics components we have manufactured, showcasing our capabilities in precision machining, material control, and quality assurance.

Robotics CNC Machining FAQs

Standard lead time is 5–10 days, with expedited options available for urgent orders, allowing delivery in as fast as 3–5 days.

Yes, we specialize in high-strength materials like 7075 aluminum, titanium (Ti-6Al-4V), stainless steel, and composites like CFRP for robotics components.

Absolutely! You can provide us with 3D files (STL, STEP, IGES), and we’ll give you a detailed quote based on material, complexity, and quantity.

Yes, we provide Certificates of Conformance (COC) and full material traceability reports for all critical parts, ensuring compliance with industry standards.

Please provide your 3D files or CAD drawings, specify material type, quantity, surface finish preferences, and any specific tolerance or assembly requirements.

Start Your Robotics CNC Machining Project Now!

Contact us for free quote and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.