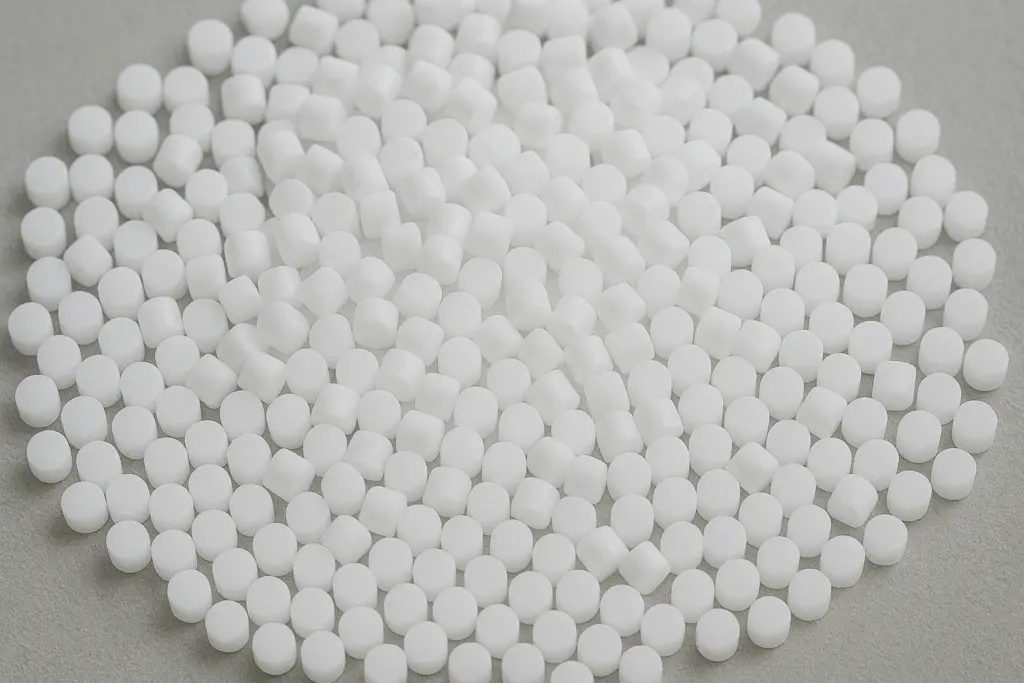

PA – Nylon

Polyamide (PA), commonly known as Nylon, is widely used for Two-Color Injection Molding due to its high strength, wear resistance, and ability to withstand high temperatures. It is commonly used in automotive, electrical, and industrial applications, where robust, durable components are required. For example, it is frequently used for gears, bearings, and electrical connectors, providing excellent mechanical properties while allowing for efficient integration with other materials in multi-component molding.

- Mill Lead Time: As fast as 5 days

- Finishes: Raw, textured, bead blasted, polished.